6 Popular Uses of Ceramic Materials in Our Daily Life

Ceramics are available in many different types, and so are their applications in the industry. Generally, in terms of applications, ceramics can be grouped as traditional ceramics and advanced ceramics. Traditional ceramics, on the one hand, are made from basic materials like clay, silica, and feldspar. Examples include bricks and porcelain articles. However, advanced ceramic materials are made up of very pure compounds, such as aluminum oxide (Al2O3), silicon nitride (Si3N4), and silicon carbide (SiC). Ceramics are applied in glasses, clay products, refractories, cement, and advanced ceramics. In this article, we’ll look at some common applications of ceramics, including advanced ceramics in daily life, as well as some common ceramics.

Common Applications of Ceramic Materials

Glasses

Glasses constitute a major application of ceramic materials in our daily life. Starting from windows, glass containers, mirrors, and lenses to glass mugs and decorations, glasses are a common group of ceramics and they offer many benefits known to man. Glasses are typically non-crystalline silicates that contain other oxides, such as calcium oxide, sodium oxide, potassium oxide, and aluminum oxide. These components influence the properties and color of the glass. glass properties and its color.

Glass-ceramics are typically polycrystalline materials manufactured by controlled crystallization of base glass. There are different types of ceramic glasses, from the glass jars in your kitchen to the bottles holding your drugs, you’ll find a wide variation in the use of ceramics as glasses in your home.

Refractories

Another common application of ceramics is in refractories. These are ceramic materials designed to withstand extreme temperatures (typically above 1,000°F), which are found in modern manufacturing. Refractories serve as heat-resistant insulators lining the hot surfaces found in a number of industrial processes. Refractories can withstand these very high temperatures without melting or decomposing. Besides, they are inert in such environments, meaning that they will not interact with the reacting components. and their inertness in severe environments. Refractories are made from both natural and synthetic materials. This can be nonmetallic or a combination of different substances, such as alumina, bauxite, dolomite, magnesite, silicon carbide, zirconia, etc. Generally, refractories are classified into two broad categories: preformed shapes (also known as specialty and monolithic refractories) and refractory ceramic fibers. The refractory ceramic fibers are similar to residential insulation. However, they insulate at relatively higher temperatures.

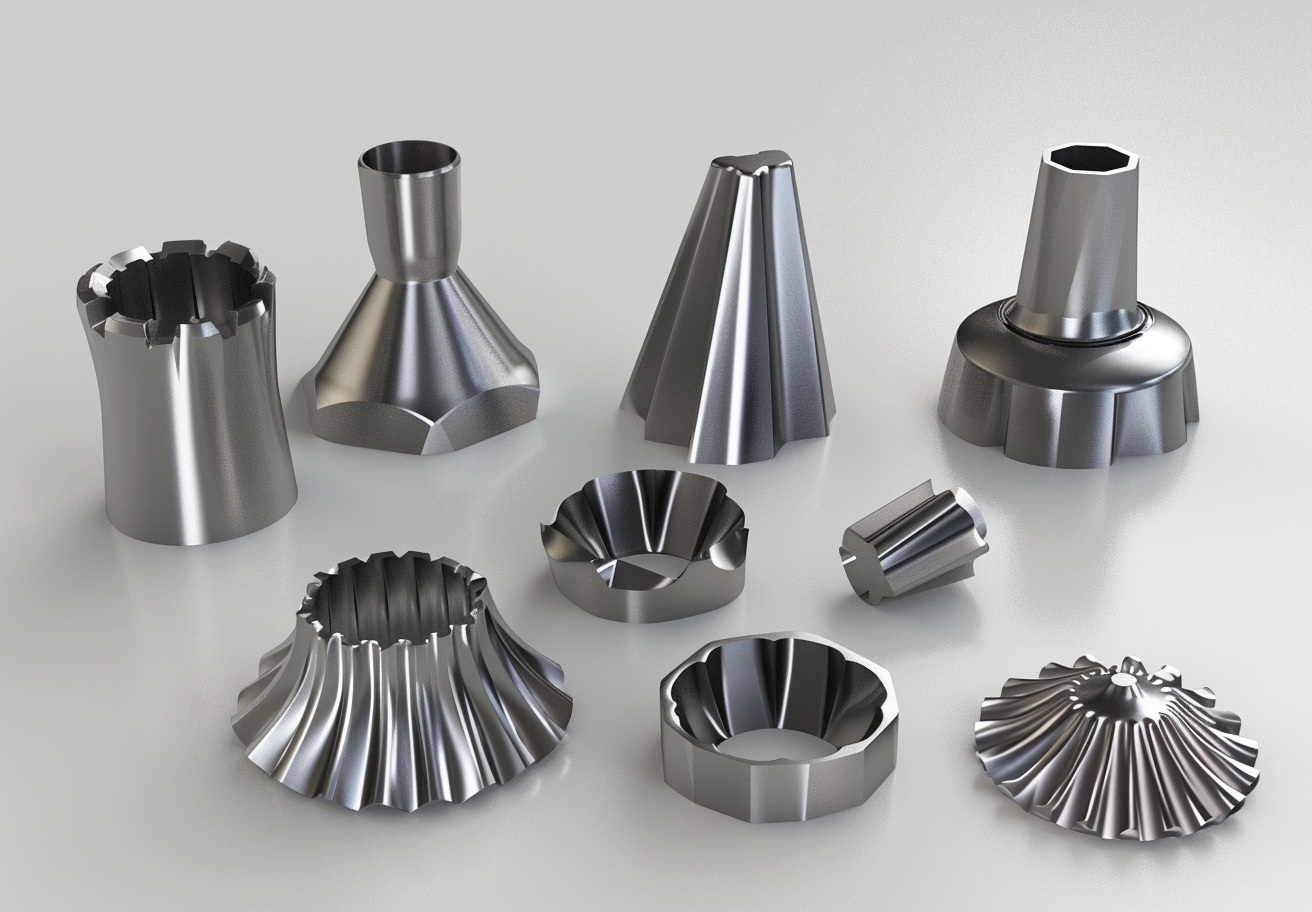

Abrasive Ceramics

As the name implies, abrasives are hard substances used in handling or cutting out other softer materials. Common examples of abrasive ceramics are diamond, silicon carbide, tungsten carbide, silica sand, aluminum oxide, etc. They also have refractory properties, which makes them resistant to extreme situations, such as high temperatures. Abrasive ceramics are tough and have high wear resistance.

Clay Products

Clay is a common and familiar form of ceramic raw material used to produce several important items for both home and office use. Clay products are found in great abundance because they are easy to make and often come out really beautiful when finished. It is found in great abundance and popular because of the ease with which products are made.

Clay products can be any of the following and even more: porcelain, pottery, chinaware, roofing tiles, fired bricks, terra-cotta, brick veneer, sculptured brick, and sewer pipes, are mainly two kinds. All these are broadly classified into two kinds of clay products: structural products and whiteware.

Cement

Cements is a category of ceramic applications that encompass products with elements of cement, such as limestone, plaster of Paris, (PoP), and actual cement. Cement is known to form slurries, which quickly solidify when mixed with water. This means that any shape can be formed from Cement. The materials are typically also utilized to bond construction bricks. Note that concrete is not exactly ceramic since it is a combination of sand and cement. The mixture only solidifies upon the addition of water the cement reacts, forming a ceramic-like structure that holds the composite particles together. The strength of the concrete is gained from a reaction between the water and the cement.

Advanced Ceramics

Other than traditional ceramics, what we have is advanced ceramics, which have been manufactured for specific applications: Advanced ceramics are usually explored for their electrical, magnetic, and optical properties. They are used in heat engines, nuclear reactor reactors, armor plates, and electronic packaging. Examples of advanced ceramic materials include titanium oxide (TiO2), titanium boride (TiB2), uranium oxide (UO2), diamond, aluminum nitride (AlN), yttrium aluminum garnet (YAG, Y3Al5O12), zirconia (ZrO2), Silica (SiO2), silicon carbide (SiC), aluminum oxide, etc. There are several other applications or uses of ceramics in our daily life. It is logical to say that ceramic plays a more role as raw material in manufacturing industries and a host of other domestic fabrication processes.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- An Overview of Nozzle Materials: Including ZSBN and Other Advanced Options

- Introduction to Magnesium Oxide Stabilized Zirconia Ceramics

- Silicon Nitride Bearing Balls: The 4000 MPa Solution for Aerospace Applications

- Boron Carbide (B10) for Effective Neutron Shielding in Nuclear Radiation

- Ceramic Materials for Surgical Devices: Al₂O₃ vs. ZrO₂