Common Materials and Properties of Industrial Ceramics

Introduction

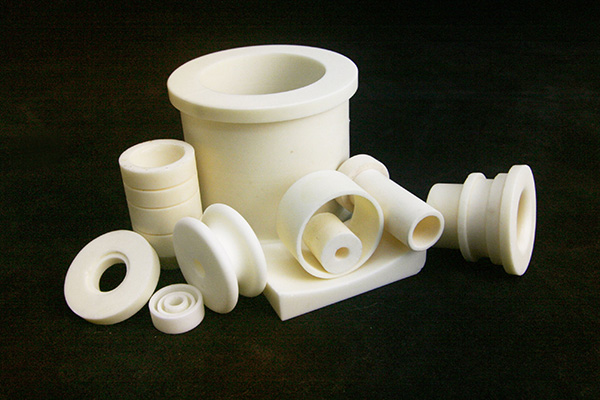

Ceramic materials have become increasingly popular in various industries for their unique properties like strength, hardness, and high-temperature resistance. This article discusses some of the most common ceramic materials used today, including aluminum oxide, zirconia, silicon nitride, graphite, and boron nitride.

Aluminum Oxide

Aluminum oxide is a porous and opaque ceramic variety commonly used in traditional pottery. It requires glazing to make it waterproof enough to hold liquid, but it is not very hard or dense compared to porcelain or clay. However, it is highly stable during production and processing, making it ideal for low-temperature baking. Aluminum oxide has multiple processing techniques, lower sintering temperatures, and is more affordable than other ceramic materials. Its typical application ranges from large-scale sanitary ware to cup and saucer products.

Material Properties

- Low sintering temperature (<1200 degrees Celsius)

- Less deformation during baking

- Various processing techniques

- Low cost

- More fragile than porcelain

Typical Applications

- Large-scale sanitary ware

- Cup and saucer products

Zirconia

Zirconia is a high-performance ceramic material that is more widely used than alumina due to its toughness. Its smaller particles make it suitable for cutting tools, pistons, bearings, and even ornate jewelry. Superfine zirconia powder or titanium carbide powder can be used in watchmaking, where they are pressed into shape, sintered at 1,450 degrees Celsius, and polished with diamond sand to give them a metallic finish. Zirconia is also used in automotive oxygen sensors, medical-biological applications, pump valves, and mechanical seals.

Material Characteristics

- Excellent strength and fracture toughness

- Super hard, super abrasion resistance

- Excellent chemical stability

- High-temperature resistance, up to 2400 degrees Celsius

- Low thermal conductivity (20% of alumina)

Typical Applications

- Cutting props and kitchen knives

- Marine fish reels, bicycle racing cars, skating shoes, and skateboards

- Automotive oxygen sensors

- Medical biological applications

- Pump valves and mechanical seals

Silicon Nitride

Silicon nitride is one of the hardest materials in the world, with excellent wear resistance, loss, and compression properties. It was discovered in the 1960s by a group of engineers looking for materials that could withstand the harsh conditions inside jet engines. Its super hardness makes it the primary bearing material in products such as Marine fish reels, bicycle racing cars, skating shoes, and skateboards.

![]()

Material Characteristics

- The friction of silicon nitride is 80% lower than that of steel

- Three times harder than steel

- 60% lighter than steel

- The operating temperature is lower than that of steel

Typical Applications

- Shuttle's main engines, military missiles, and gyroscopes

- Marine fish reels, bicycle racing cars, skating shoes, and skateboards

Graphite

Graphite's physical properties often make it a member of the ceramic family. It has a wide range of uses, from everyday applications like coins to high-end sporting goods like tennis rackets and golf clubs. Graphite's layered structure gives it a smooth, distinctive feel and makes it an excellent lubricant at high temperatures. Its ability to withstand high temperatures has led to its use in refracting telescopes, space shuttles, and vehicles.

Material Properties

- Absorbable energy

- Good strength-to-weight ratio

- Small coefficient of friction

- Non-toxic

- Excellent machining performance

- Good resistance to chemical corrosion

- Good electrical conductivity

- Stable at high temperatures, high strength

- Excellent thermal shock resistance

Typical Applications

- Graphite pencils

- Refracting telescopes, space shuttles, and vehicles

- Conformable materials enhance plasticity, make products more flexible, promote energy absorption, and enhance strength and hardness

Boron Nitride

Boron nitride is often used in cosmetics, where it is added to ingredients to make the skin look softer and smoother. Various grades are used in a wide variety of products, with cubic boron nitride being one of the hardest materials in the world and excellent for making cutting tools. Boron nitride is divided into two types: hexagonal boron nitride, which is similar to graphite and has high-temperature resistance, and cubic boron nitride, which has excellent hardness and is commonly used for cutting, grinding, and drilling.

Material Properties

- Silky smooth

- Excellent adhesion

- There are various levels of products, that can be widely used in a large number of products

- Inconvertibility

- Good lubricity

- Chemical inactivity

- Non-toxic

Typical Applications

- Cosmetics such as foundation cream, lipstick, eyebrow pencil, etc.

- Raw materials and industrial production and processing of friction reduction

- Cutting, grinding, and drilling

Conclusion

In conclusion, ceramic materials have come a long way and have become an essential component in various industries due to their unique properties such as strength, hardness, and high-temperature resistance. Aluminum oxide, zirconia, silicon nitride, graphite, and boron nitride are just a few examples of the different types of ceramic materials available, each with their own set of distinct characteristics and applications. With continued research and development, ceramic materials will continue to play a vital role in modern technology and manufacturing processes.

Advanced Ceramic Materials (ACM) supplies high-quality industrial ceramics and related products to meet our customers' R&D and production needs. For more information, please visit https://www.preciseceramic.com/.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Alumina vs. Beryllia: Comprehensive Comparison of Thermal Conductivity, Electrical Resistivity, and Cost

- Ceramic Material Selection Made Easy: A Buyer's Guide to Key Properties

- A Comprehensive Guide to Silicon Monoxide (SiO) and Its Applications

- Main Production Methods of SIlicon Carbide Ceramics

- Applications of ZSBN Ceramics: Molds and Nozzles for Molten Metal Handling