Do you have any questions? Email Us

[email protected]

High-tech precision ceramics have come a long way since their inception. Initially developed in the early 2000s by Chanel, these high-temperature hard ceramics were created by adding precious metals like titanium and iridium to natural mineral powders of zirconium dioxide and yttrium. These materials were then roasted at over 1000 degrees Celsius, subjected to rigorous testing and machine polishing, resulting in a unique high-tech precision ceramic with superior hardness and temperature resistance.

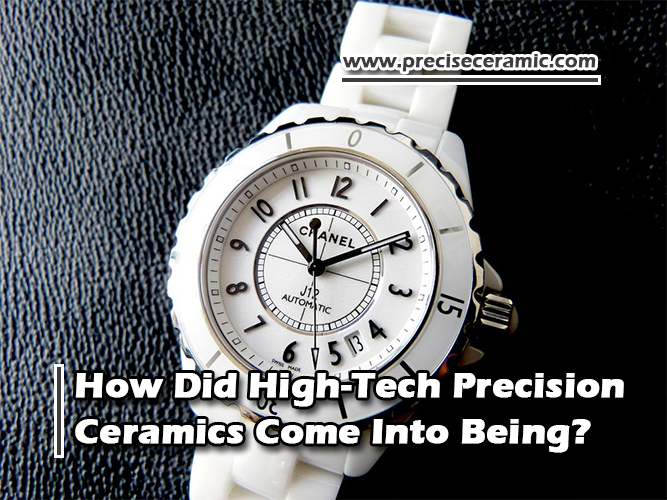

The first high-tech precision ceramics made a splash in the fashion industry when Chanel introduced them in their wristwatch jewelry store in Paris's Fontainebleau square. The deep, dark sheen of the ceramic made it an instant hit with consumers, who appreciated the lightweight, non-wear, non-fading, and comfortable properties of the material.

Today, high-tech precision ceramics have become a staple in the watchmaking industry, with leading brands like Rado and Chanel incorporating them into their watches' cases and straps. The added elements determine the color of the ceramic, with titanium-coated ceramics appearing silver-gray, while iridium metal creates mostly white ceramics.

In addition to their aesthetic appeal, high-tech precision ceramics are also known for their excellent properties, such as lightweight, high hardness, non-wear, non-fading, and comfort, among others. These characteristics make high-tech precision ceramics a favorite among consumers and manufacturers alike.

One of the most significant advantages of high-tech precision ceramics is that they can be manufactured in different colors, making them versatile for use in various applications. For instance, RADO radar meters use ultra-light high-tech ceramic Si3N4TiN to create diamond bar series wristwatches that appear in different old bronze colors.

In conclusion, the evolution of high-tech precision ceramics has been impressive since Chanel first introduced them in the early 2000s. Their superior hardness, temperature resistance, and aesthetic appeal have made them a staple in the watchmaking industry. Manufacturers like Advanced Ceramic Materials (ACM) continue to supply high-quality zirconia ceramics and related products to meet the R&D and production needs of consumers.