An Overview of Pyrolytic Boron Nitride Ceramic Materials

About PBN

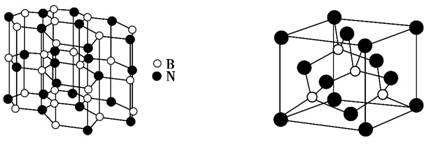

Pyrolytic boron nitride is abbreviated as Pyrolytic BN or PBN, also known as Chemical vapor-deposited Boron Nitride, or CVD-BN, since PBN is mainly obtained by chemical vapor deposition. When it comes to boron nitride, we must talk about its two main structures: hexagonal and cubic. Hexagonal boron nitride and graphite are very similar in many respects, and thus hexagonal boron nitride is also called white graphite. (Related: Detailed Introduction to Boron Nitride Structure) The pyrolytic boron nitride we talked about is the hexagonal boron nitride. The PBN prepared by chemical vapor deposition is characterized by excellent thermal stability, intrinsic purity, and much greater mechanical strength, which make PBN very attractive to many industry sectors such as semiconductor, photovoltaic, coatings on graphite, and crystal growth crucibles.

Structure of PBN

Pyrolytic boron nitride (PBN) belongs to the hexagonal system and is a typical layered material. The inter-layer and intra-layer atom spacing are quite different: the inter-layer atom spacing is 3.33, and the intra-layer atom spacing is 1.45. The structure of the PBN is composed of B and N atoms alternately arranged in the layer and in the C-axis direction, respectively. It can be observed under a high power microscope that PBN exhibits stacking faults, resulting in the average layer spacing greater than the theoretical layer spacing.

Features of PBN

PBN is an advanced material with excellent properties. It is deposited by the reaction of ammonia and boron halide under high temperature and high vacuum conditions. It can be deposited as PBN sheet material or directly into PBN final products such as tubes, rings or thin-walled containers. Unlike ordinary hot-pressed boron nitride (BN), PBN does not have to undergo a conventional hot press sintering process and does not add any sintering agent, so the obtained product has the following remarkable features:

- Excellent thermal conductivity

- Extreme high purity with low density

- High insulation resistance

- High dielectric strength over a wide range of temperatures

- Non-wetting

- Non-toxic

- Non-reactive to most other compounds

- Very easily machined

Compared with normal boron nitride ceramic, pyrolytic boron nitride (PBN) has a much better purity level and density. Advanced Ceramic Materials (ACM) provides PBN crucibles with high purity and competitive price. We offer LEC crucibles, MBE crucibles, and VGF crucibles made by the CVD process with PBN material. Please visit https://www.preciseceramic.com/ for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Why Alumina Grinding Balls Are Replacing Steel Across Multiple Industries

- Case Study: Replacing Alumina Tubes with Mg-Stabilized Zirconia to Meet 1850°C Demands

- Case Study: Why 95% Alumina Beats 99% in Thermal Cycling

- Guide to Alumina Grinding Balls: Properties, Applications, and Selection

- Understanding DFARS Compliance: What It Means for Material Sourcing and Why It Matters