Spherical Ceramic Powder

Spherical ceramic powder, characterized by its finely crafted spherical particles, offers enhanced flowability, packing density, and sintering behavior. This specialized form is utilized across industries for applications demanding precise material properties.

Spherical Ceramic Powder Properties:

- Enhanced Strength

- Tailored Conductivity

- Thermal Stability

- Biocompatibility

- Miniaturized Dimensions

Spherical Ceramic Powder Key Characteristics

- Uniform Spherical Shape: The standout feature of this powder lies in its shape. The particles are deliberately designed to be spherical, promoting homogeneity in size and morphology. This uniformity plays a crucial role in achieving consistent results in various applications.

- High Purity: Spherical Ceramic Powder boasts high purity levels, minimizing the presence of impurities. This purity is a vital factor in applications where material integrity and performance are paramount, such as electronics and biomedical devices.

- Controlled Particle Size Distribution: The manufacturing process ensures precise control over the particle size distribution. This attribute allows engineers and manufacturers to tailor the powder for specific applications, providing flexibility and customization.

- Enhanced Flowability: The spherical shape contributes to improved flowability during processing. This is particularly beneficial in applications where the powder needs to flow smoothly, such as in coatings and additive manufacturing processes.

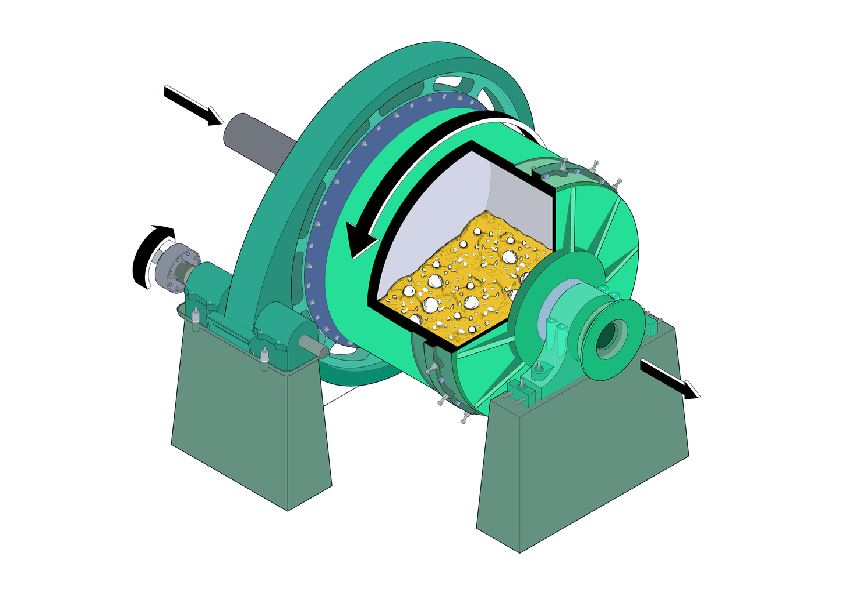

- Optimized Packing Density: Achieving high packing density is crucial in material compaction. The uniform shape of the spherical particles facilitates efficient packing, enhancing the overall density of the final product.

- Improved Sintering Behavior: Sintering, a process of compacting and forming a solid mass from powder, is significantly improved with Spherical Ceramic Powder. The particles sinter more effectively, resulting in denser and stronger final products.

- Smooth Surface Finish: The smooth and uniform surface finish of the spherical particles is advantageous in applications where a flawless appearance is essential. Coatings and surfaces benefit from the even distribution and adherence of these particles.

Spherical Ceramic Powder Applications

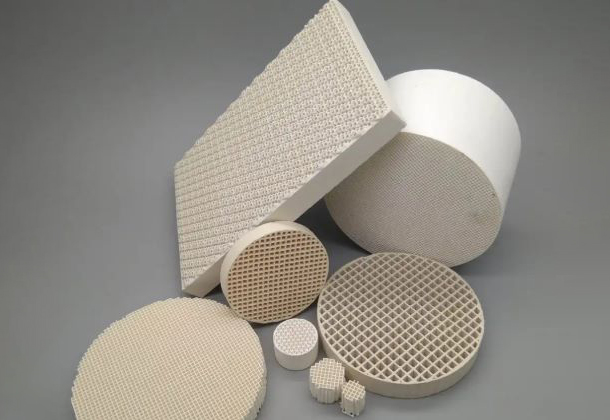

- Advanced Ceramics Manufacturing: Spherical Ceramic Powder finds extensive use in the production of advanced ceramics for industries ranging from aerospace to electronics.

- Coatings and Surface Treatments: Industries requiring precise and uniform coatings, such as automotive and aerospace, utilize this powder to achieve superior surface finishes.

- Additive Manufacturing: In the realm of additive manufacturing or 3D printing, especially in powder bed fusion processes, Spherical Ceramic Powder plays a crucial role in creating intricate and high-quality ceramic components.

- Electronics and Semiconductor Industry: The material's properties make it ideal for fabricating components used in electronic devices and semiconductor manufacturing.

- Biomedical Applications: Spherical Ceramic Powder is applied in the biomedical field for creating biocompatible ceramics, especially in the development of medical implants and devices.

- Energy Storage Systems: The material contributes to the production of ceramic components used in batteries and other energy storage devices.

- Precision Equipment Components: Manufacturing precision components for machinery and equipment benefits from the unique characteristics of Spherical Ceramic Powder.

Your Spherical Ceramic Powder Supplier

Advanced Ceramic Materials is a leading supplier of spherical ceramic powder products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us for any questions about spherical or other ceramic materials that are not listed on the website.

FAQs

What Are the Key Characteristics of Spherical Ceramic Powder?

How Does the Uniform Spherical Shape Impact the Performance of Spherical Ceramic Powder in Applications?

What Role Does Spherical Ceramic Powder Play in Additive Manufacturing or 3 D Printing?

Unsure Which Ceramic Material to Choose?