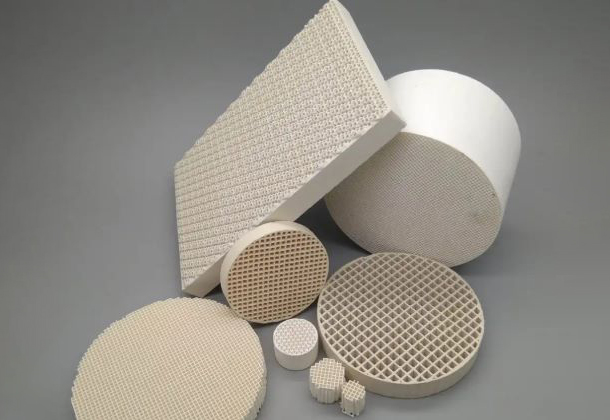

Metal Coated Substrate

Metal Coated Substrate is a composite material composed of a base substrate, typically ceramic or polymer, that has been coated with a thin layer of metal. This combination enhances the substrate's properties by providing improved electrical conductivity, thermal management, corrosion resistance, and mechanical strength. Metal Coated Substrates are widely used in industries such as electronics, optics, aerospace, medical devices, and energy solutions due to their versatility and superior performance characteristics.

Key Features:

- Excellent Electrical Conductivity

- Superior Thermal Management

- High Corrosion Resistance

- Enhanced Mechanical Strength

- Diverse Metal Options

Application Areas

Our Metal Coated Substrates are widely utilized across various industries, meeting diverse high-performance requirements. Below are the primary application areas:

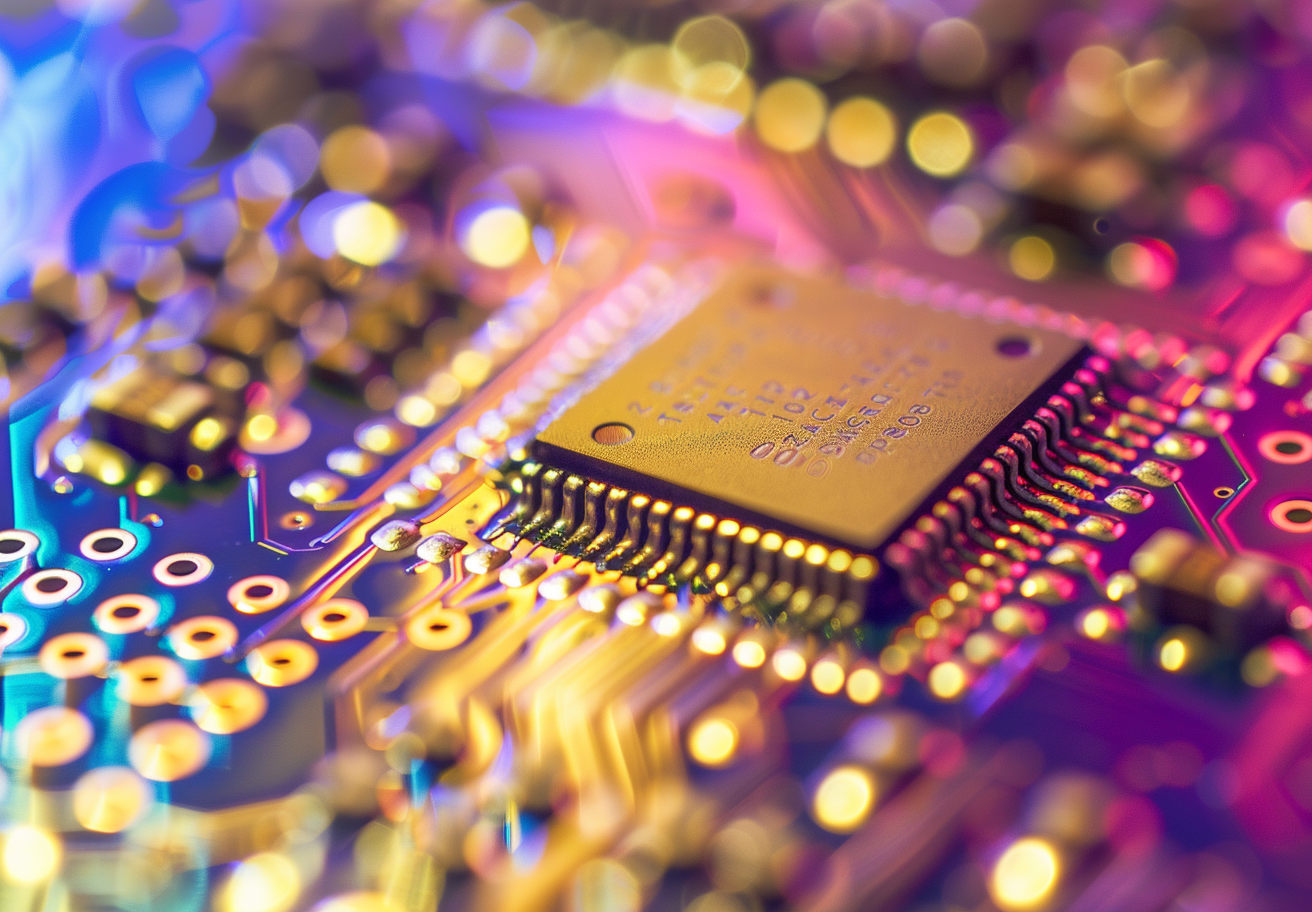

Electronics and Electrical

In the electronics and electrical sector, Metal Coated Substrates are used for high-frequency circuit boards, heat sinks, connectors, and other critical components. Their excellent electrical conductivity and thermal management capabilities ensure efficient operation and stability of devices.

Optics and Display

In optical and display technologies, Metal Coated Substrates are employed in the fabrication of high-reflectivity mirrors, optical sensors, and high-resolution display panels. Precise metal coatings guarantee exceptional performance and clarity in optical equipment.

Aerospace

The aerospace industry relies on Metal Coated Substrates for structural components, missile guidance systems, and protective coatings. Their high strength and corrosion resistance ensure reliability and longevity under extreme conditions.

Medical Devices

In the medical field, Metal Coated Substrates are applied in diagnostic instruments, sensors, and implantable devices. Antimicrobial properties and high conductivity make them ideal for high-precision medical equipment, ensuring patient safety and device stability.

Energy Solutions

Metal Coated Substrates play a crucial role in the energy sector, used in solar panels, fuel cells, and energy storage systems. Their superior thermal and electrical conductivity enhances energy conversion efficiency and overall system performance.

Product Categories

We offer a diverse range of Metal Coated Substrates to meet the specialized needs of different application areas. Below are the main product categories:

Aluminum Coated Substrates

Aluminum Coated Substrates are renowned for their high reflectivity and outstanding thermal management capabilities. They are ideal for applications requiring efficient heat dissipation and reflective properties, such as heat sinks and reflectors.

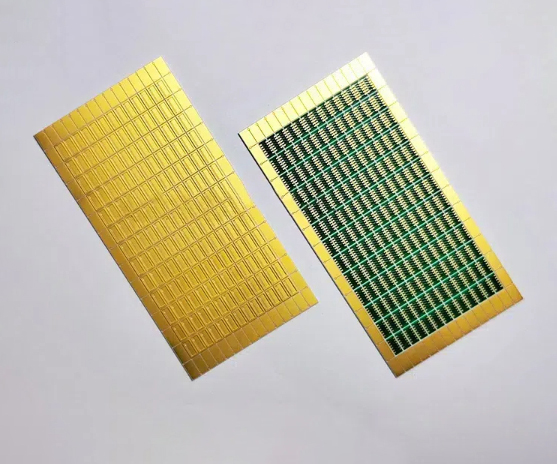

Copper Coated Substrates

Copper Coated Substrates provide excellent electrical conductivity and thermal dissipation performance. They are the perfect choice for high-performance electronic components and thermal management systems, ensuring efficient device operation.

Silver Coated Substrates

Silver Coated Substrates offer superior electrical conductivity and antimicrobial properties, making them particularly suitable for advanced electronics and medical devices. Their high electrical performance and hygienic characteristics add extra value to your products.

Nickel Coated Substrates

Nickel Coated Substrates are distinguished by their high corrosion resistance, widely used in industrial and mechanical applications. Their durability and stability ensure long-term use in harsh environments.

Multi-Layer Metal Coated Substrates

Multi-Layer Metal Coated Substrates combine the advantages of different metal layers to achieve specific performance requirements. Through customized metal combinations, we provide solutions that meet complex application demands, ensuring optimal overall performance.