Silicon Oxide

Silicon oxide, often referred to as silica (SiO₂), is a highly versatile and widely utilized ceramic material, known for its exceptional properties that are essential in numerous industries. As one of the most plentiful compounds on Earth, silica occurs naturally in quartz and many living organisms. It is a key component in the production of various products, from common glass to advanced ceramics.

Properties of Silicon Oxide Ceramic

Silicon oxide is renowned for its exceptional thermal stability, high hardness, and impressive chemical resistance. These characteristics make it ideal for applications that demand durability and reliability under extreme conditions. Silica is also an excellent electrical insulator, which contributes to its use in electronic and semiconductor industries.

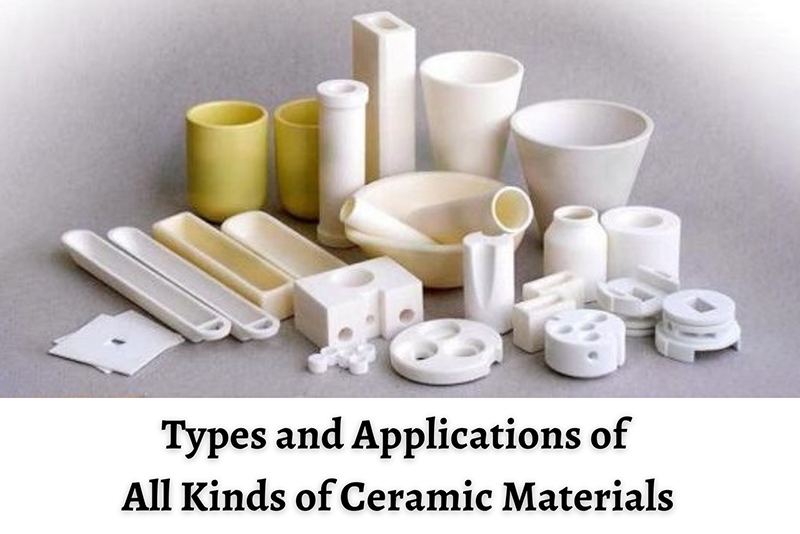

Applications of Silicon Oxide Ceramic

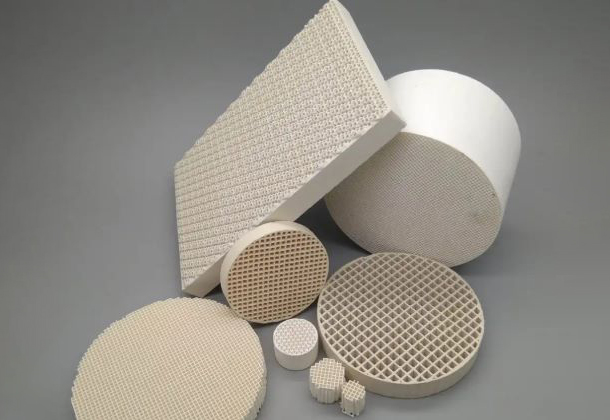

The applications of silicon oxide ceramics are extensive and diverse. In the glass industry, silica is the primary ingredient used to produce different types of glass, including optical, container, and flat glass. Its chemical inertness makes it an essential material for coatings and refractories, protecting surfaces from heat and corrosion.

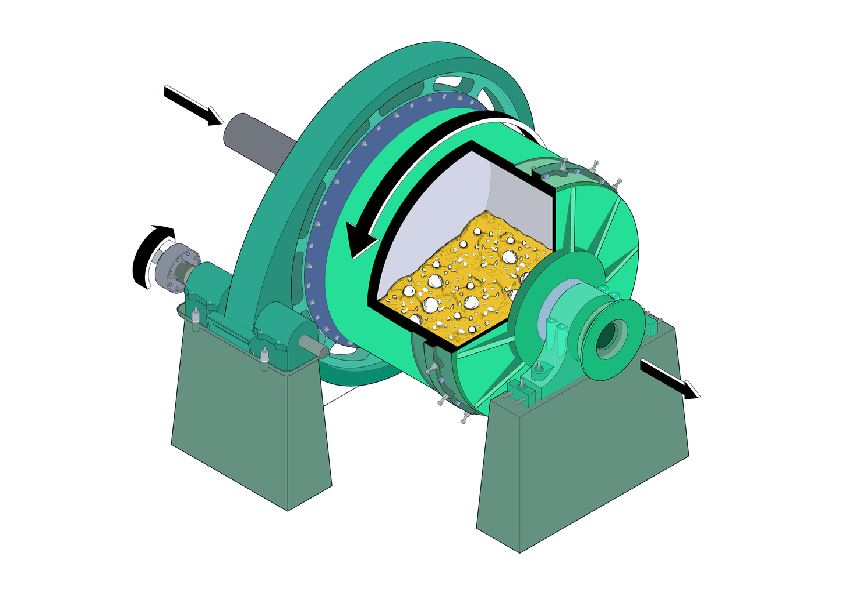

In advanced ceramics, silicon oxide is utilized to create components that require high strength and resistance to wear and tear, such as in aerospace, automotive, and industrial machinery. Additionally, in the electronics sector, silica is a key material in the production of insulators, substrates, and other components critical to the performance of electronic devices.

Why Choose Silicon Oxide Ceramic?

The unique combination of properties—thermal stability, hardness, and chemical resistance—makes silicon oxide ceramic a top choice for engineers and manufacturers looking for a material that can withstand harsh environments while maintaining performance. Whether in traditional applications like glassmaking or in cutting-edge technologies, silicon oxide continues to be a material of choice for industries aiming for high performance and reliability.

Explore the full potential of silicon oxide ceramic and discover how it can enhance the durability and efficiency of your products.