Diverse Classification Factors of Boron Nitride and Their Correlation with PBN, HBN, CBN, and ZSBN Variants

Introduction

Boron Nitride (BN), with its diamond-like hardness and graphite-like lubricity, stands out in the material science world for its exceptional properties and versatility. This compound exists in several forms, each suited to specific industrial applications, ranging from electronics to aerospace. Key variants include Pyrolytic Boron Nitride (PBN), Hexagonal Boron Nitride (HBN), Cubic Boron Nitride (CBN), and Zirconia Stabilized Boron Nitride (ZSBN), each offering unique properties such as high thermal conductivity, electrical insulation, and mechanical strength.

This article delves into the classification factors of BN, exploring how chemical composition, physical and mechanical properties shape its applications. We will also examine the production processes, key properties, and uses of BN's main variants, providing insights into their comparative analysis and application-specific decision criteria. Through this exploration, we aim to highlight the current and future potential of Boron Nitride in technological advancements.

Here is a QUICK GUIDE for this article:

- Variants of Boron Nitride

- Pyrolytic Boron Nitride (PBN)

- Hexagonal Boron Nitride (HBN)

- Cubic Boron Nitride (CBN)

- Zirconia Stabilized Boron Nitride (ZSBN)

- Classification Factors of Boron Nitride

- Chemical Composition and Structure

- Physical Properties

- Mechanical Properties

- Correlation Among PBN, HBN, CBN, and ZSBN

- Comparative Analysis

- Decision Criteria for Application-Specific Use

- Future Potential Based on Current Research Trends

- Challenges and Opportunities

Variants of Boron Nitride

Boron Nitride (BN) presents in various forms, each tailored for specific applications thanks to their unique properties. Here, we delve into the four primary variants: Pyrolytic Boron Nitride (PBN), Hexagonal Boron Nitride (HBN), Cubic Boron Nitride (CBN), and Zirconia Stabilized Boron Nitride (ZSBN).

Pyrolytic Boron Nitride (PBN)

- Production Process: PBN is produced through chemical vapor deposition (CVD), involving the reaction of boron halides with ammonia or nitrogen at high temperatures.

- Key Properties: PBN is known for its high purity, excellent thermal stability, and uniformity. It also has great dielectric strength and is non-toxic.

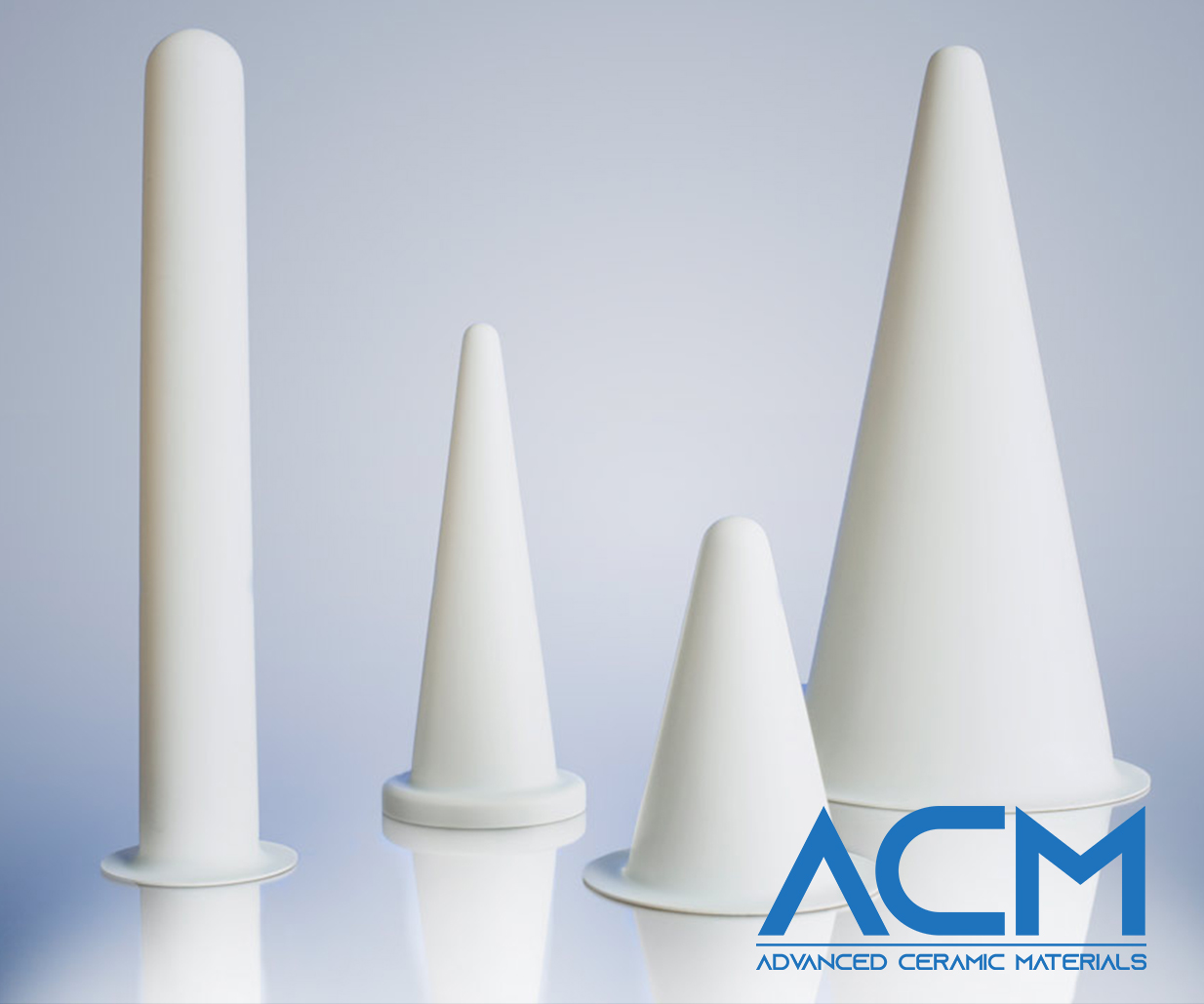

- Applications: Utilized in semiconductor manufacturing for insulators, crucibles, and boats due to its high thermal resistance and purity.

Hexagonal Boron Nitride (HBN)

- Production Process: HBN is synthesized through a high-temperature, high-pressure process that mimics the natural formation of graphite.

- Key Properties: It exhibits a graphite-like layered structure, providing excellent lubricative properties, thermal stability, and electrical insulation.

- Applications: Commonly used as a lubricant, in thermal spray coatings, and in cosmetic products due to its softness and health safety.

Cubic Boron Nitride (CBN)

- Production Process: CBN is produced by treating HBN at extremely high pressure and temperature, similar to the process used to create synthetic diamonds.

- Key Properties: CBN is one of the hardest materials known, second only to diamond. It also has high thermal conductivity and chemical stability.

- Applications: Primarily used in cutting and grinding tools, where its hardness enables it to cut hard materials like steels and ceramics.

Zirconia Stabilized Boron Nitride (ZSBN)

- Production Process: ZSBN is created by adding zirconia to BN, enhancing its thermal shock resistance and mechanical strength through a sintering process.

- Key Properties: It combines the thermal stability of BN with the toughness of zirconia, offering improved thermal shock resistance.

- Applications: Ideal for applications requiring high toughness and thermal stability, such as in aerospace and defense sectors.

Here's a comparative table summarizing the key aspects of the Boron Nitride (BN) variants:

|

Variant |

Production Process |

Properties (Advantages) |

Applications |

Temperature Resistance |

Electrical Resistivity (Ω·cm) |

Hardness (GPa) |

|

CVD |

High purity, stability, dielectric strength |

Semiconductor, insulators |

Up to 2000°C in vacuum |

>10¹⁶ |

2 |

|

|

High-temp, high-pressure synthesis |

Lubricity, stability, insulation |

Lubricants, coatings, cosmetics |

Up to 1000°C in air |

10¹⁴ to 10¹⁵ |

1-2 |

|

|

High pressure & temperature |

Extreme hardness, conductivity, stability |

Cutting/grinding tools |

Up to 1400°C in inert |

10¹⁰ to 10¹² |

45-50 |

|

|

Zirconia sintering |

Stability, toughness, shock resistance |

Aerospace, defense |

Up to 1500°C in air |

10¹⁴ |

3-4 |

This table provides a clear overview of each BN variant, highlighting their distinct production processes, key properties, and applications, thus offering insights into their suitability for various industrial and technological uses.

Classification Factors of Boron Nitride

Boron Nitride (BN), a material with exceptional versatility and performance in various applications, owes its unique properties to several key classification factors. These factors include chemical composition and structure, physical properties, and mechanical properties. Understanding these factors is crucial for tailoring BN to specific applications, maximizing its effectiveness and efficiency.

Chemical Composition and Structure

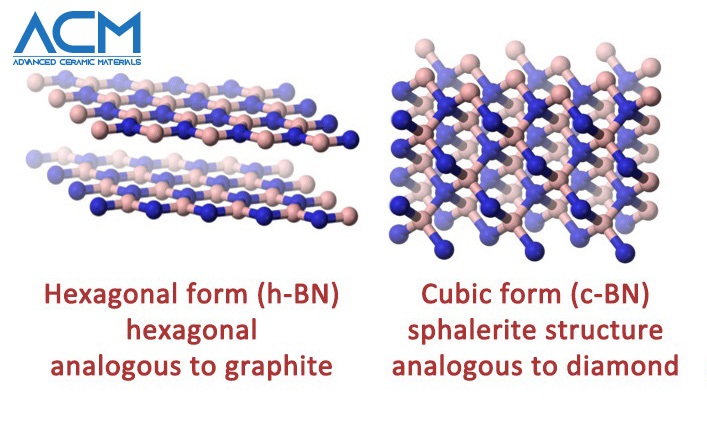

BN's ability to mimic the structures of carbon allotropes allows it to exhibit a range of properties. Its chemical composition—consisting of equal numbers of boron and nitrogen atoms—enables it to form structures that are analogs of graphite and diamond, known as hexagonal boron nitride (HBN) and cubic boron nitride (CBN), respectively. This structural versatility is the foundation of BN's wide-ranging applications, from lubricants to cutting tools.

Read more: Hexagonal Boron Nitride VS. Cubic Boron Nitride

Physical Properties

- Thermal Conductivity: BN variants exhibit remarkable thermal conductivity, with CBN and PBN, in particular, standing out for their ability to efficiently dissipate heat, making them ideal for thermal management applications in electronics and aerospace.

- Electrical Insulation: Despite its high thermal conductivity, BN is an excellent electrical insulator across all its forms. This property is invaluable in electrical and electronic applications, where materials must withstand high temperatures without conducting electricity.

Mechanical Properties

- Hardness: CBN is noted for its extreme hardness, surpassed only by diamond. This makes it suitable for cutting and grinding applications where conventional materials fail.

- Flexural Strength: The ability of a material to withstand bending forces, or flexural strength, is critical in structural applications. PBN and ZSBN, with their high flexural strength, are preferred materials for components that require high mechanical integrity under stress.

The interplay between these classification factors determines the suitability of BN variants for specific uses. For instance, the high thermal conductivity and electrical insulation properties make BN an excellent candidate for electronic substrates and insulators, while its mechanical properties are leveraged in abrasive and cutting tools.

Understanding these classification factors not only aids in selecting the appropriate BN variant for an application but also in developing new BN-based materials tailored for future technological advances and applications.

Correlation Among PBN, HBN, CBN, and ZSBN

The diverse variants of Boron Nitride (BN) - Pyrolytic Boron Nitride (PBN), Hexagonal Boron Nitride (HBN), Cubic Boron Nitride (CBN), and Zirconia Stabilized Boron Nitride (ZSBN) - each possess unique properties tailored for specific applications. The correlation among these variants can be understood through their comparative analysis based on the classification factors discussed earlier: chemical composition and structure, physical properties, and mechanical properties.

Comparative Analysis

- Chemical Composition and Structure: All BN variants share the same chemical composition of boron and nitrogen but differ significantly in their structure. HBN's graphite-like structure offers excellent lubricity, making it ideal for applications requiring low friction. In contrast, CBN's diamond-like structure provides extreme hardness, suitable for cutting tools. PBN, produced via chemical vapor deposition, offers high purity and thermal stability, while ZSBN's incorporation of zirconia enhances its toughness and thermal shock resistance.

- Physical Properties: Thermal conductivity and electrical insulation are two key physical properties where BN variants excel, albeit to varying degrees. PBN and CBN, in particular, show high thermal conductivity, essential for heat dissipation in electronic devices. All variants exhibit excellent electrical insulation, a critical feature for electronic substrates and components.

- Mechanical Properties: The hardness of CBN stands out, making it the material of choice for abrasive and cutting applications. PBN and ZSBN, with their superior flexural strength, are preferred in structural applications where high mechanical integrity is required under thermal stress.

Decision Criteria for Application-Specific Use

The selection of a specific BN variant for an application depends on a careful consideration of these properties. For instance, CBN is chosen for abrasive tools due to its hardness and thermal conductivity, while HBN is favored in applications requiring good lubrication and thermal stability. PBN's exceptional thermal stability and purity make it ideal for semiconductor manufacturing, and ZSBN's toughness and thermal shock resistance suit it for demanding environments like aerospace.

Future Potential Based on Current Research Trends

Ongoing research into BN materials focuses on enhancing their properties and discovering new applications. For example, advancements in CVD techniques could further improve PBN's purity and thermal properties, expanding its use in high-temperature applications. Similarly, the development of composite materials combining BN variants with other materials could lead to innovations in electronics, aerospace, and beyond.

Challenges and Opportunities

The main challenge in the wider adoption of BN variants lies in their production cost and complexity. However, the continuous improvement in synthesis methods and the exploration of new applications present significant opportunities for the BN market.

Conclusion

In wrapping up our exploration of Boron Nitride (BN) and its variants—PBN, HBN, CBN, and ZSBN—we've delved into their indispensable roles across a spectrum of applications, showcasing the material's versatility and significance in current and future technologies. Each variant's unique properties cater to specific needs, from thermal management to abrasive tools, highlighting the adaptability of BN to meet diverse engineering challenges. The progress in research and development promises to unlock even greater potentials of these materials. Suppliers like Advanced Ceramic Materials, offering a comprehensive range of BN variants, support the ongoing innovation by ensuring the availability of high-quality materials for research and industrial applications. This collaborative ecosystem between material suppliers and innovators is pivotal in driving the advancements in materials science, paving the way for new technologies that leverage the unique benefits of BN and its variants.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments