Comparing Alpha and Beta Phase Silicon Nitride

Introduction

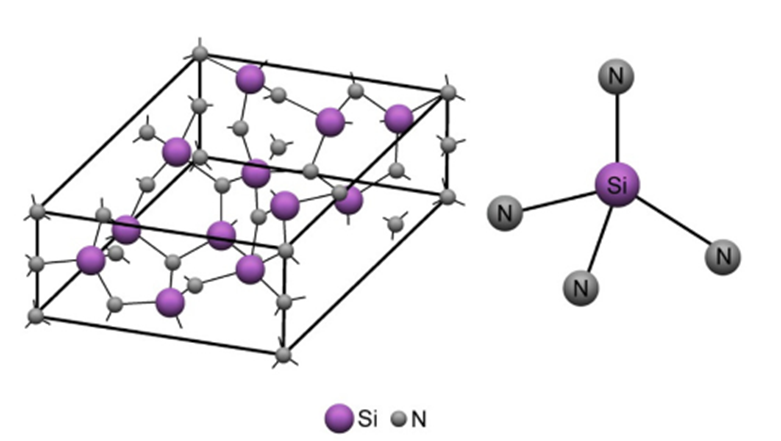

Silicon nitride is a versatile ceramic with different atomic lattice arrangements that give it unique structural properties. These structural variations give rise to distinctive phases with varying properties, making Si3N4 a remarkable material with diverse applications.

Si3N4 has two main forms: α-Si3N4 and β-Si3N4. These forms are significant in various industries and technologies because of their distinct crystal structures and properties.

Figure 1. Crystal Structure of Si3N4

1. α-Si3N4 (Alpha Phase)

α-Si3N4 (Alpha Phase) is an important form of silicon nitride with unique qualities and many uses.

- Trigonal Crystal Structure: α-Si3N4 features a trigonal crystal structure characterized by a repeating unit cell with sixfold symmetry.

- Moderate Temperature Stability: This phase exhibits stability at moderately high temperatures, typically up to around 1300°C.

- Oxidation Resistance: α-Si3N4 is resistant to oxidation at moderate temperatures, making it suitable for applications where oxygen exposure is a concern.

- Applications: It finds use in various applications, including refractories, bearings, cutting tools, and wear-resistant components.

2. β-Si3N4 (Beta Phase)

β-Si3N4 (Beta Phase) is another structural form of silicon nitride (Si3N4) known for its unique properties and wide-ranging applications:

- Hexagonal Crystal Structure: β-Si3N4 possesses a hexagonal crystal structure, known for its symmetrical cubic unit cell arrangement.

- High-Temperature Stability: In contrast to α-Si3N4, β-Si3N4 exhibits remarkable thermal stability at higher temperatures, typically up to around 1900°C.

- Mechanical Robustness: It boasts superior mechanical properties, making it ideal for applications that demand strength, toughness, and resistance to extreme conditions.

- Applications: β-Si3N4 is used in hot environments for aerospace parts, cutting tools, and bearings that endure strong mechanical and thermal forces.

The two main phases of Si3N4 have different benefits and drawbacks. This helps engineers and researchers pick the right phase for their needs.

Table 1. α-Si3N4 VS. β-Si3N4

|

|

α-Si3N4 |

β-Si3N4 |

|

Crystal Structure |

the trigonal Si3N4 phase; |

the hexagonal Si3N4 phase; |

|

Density |

lower density compared to β-Si3N4; |

higher density compared to α-Si3N4; |

|

Temperature Stability |

stable at lower temperatures, typically up to around 1300°C; |

stable at higher temperatures, typically up to around 1900°C; |

|

Properties |

good oxidation resistance at moderate temperatures, and is suitable for applications where high-temperature stability is not required; |

higher density, better high-temperature stability, and improved mechanical properties compared to α-Si3N4; |

Clarification on the Cubic Phase (γ-Si3N4):

In addition to the α and β phases, silicon nitride also has a cubic phase known as γ-Si3N4. This γ phase is distinct from the α and β phases and is characterized by a cubic (spinel-type) crystal structure. However, it is not commonly encountered under normal conditions because it requires very high temperature and very high pressure to form. Due to these stringent synthesis conditions, γ-Si3N4 is much less common in practical applications compared to the α and β phases.

Other Types of Silicon Nitride

However, there are additional types and modifications of silicon nitride, which are important in various applications. Here are some of the key types of silicon nitride:

1. Amorphous Si3N4: This form of silicon nitride lacks a well-defined crystal structure and is non-crystalline or amorphous. It is used in applications such as thin-film coatings, insulators, and electrical insulating materials.

2. SiAlON (Silicon Aluminum Oxynitride): SiAlON ceramics are a family of materials that contain silicon, aluminum, oxygen, and nitrogen. They have various compositions and can be tailored for specific properties, including high-temperature resistance and high strength.

3. Sialon (Silicon Nitride-Aluminum Oxide): Sialon ceramics are a subset of SiAlON ceramics with a specific range of compositions. They are known for their excellent mechanical properties, resistance to wear, and high-temperature stability.

4. Liquid Phase Sintered Si3N4: This method involves incorporating a sintering aid, like yttrium oxide, into the Si3N4 powder during the sintering procedure. This leads to enhanced densification and can be customized for particular uses.

5. Hot Isostatic Pressed (HIPed) Si3N4: HIPed Si3N4 is a strong material. It is made by using high pressure and temperature with an inert gas. This process yields dense and robust Si3N4 parts.

Conclusion

In summary, the choice between α-Si3N4 and β-Si3N4 depends on the specific requirements of an application. If you need high-temperature stability and excellent mechanical properties, you often prefer β-Si3N4. On the other hand, if lower-temperature applications with good oxidation resistance are more critical, α-Si3N4 may be suitable. Both phases offer advantages and limitations, and you should select based on the specific demands of the intended use.

Advanced Ceramic Materials (ACM) stands at the forefront as a premier supplier of top-tier silicon nitride ceramic products. For any inquiries regarding different types of Si3N4 or other ceramic materials, please don't hesitate to reach out to us. You can also check the following table for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments