The Essential Guide to Understanding Barium Titanate and Its Applications

Introduction

Barium Titanate (BaTiO3) is a versatile ceramic material renowned for its exceptional electrical properties. It plays a pivotal role in modern technology, making it indispensable in various industrial, medical, and electronic applications. This guide aims to provide a comprehensive understanding of Barium Titanate, its properties, production, and wide-ranging applications, especially for those looking to purchase this critical material.

What is Barium Titanate?

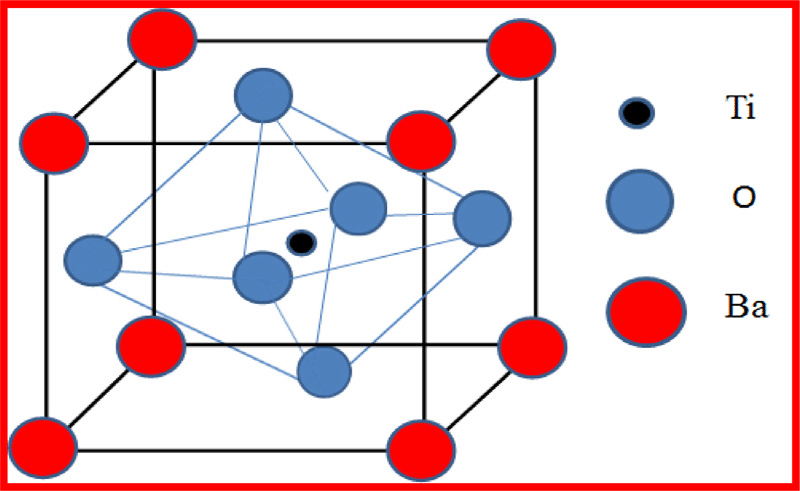

Barium Titanate is a ferroelectric ceramic material with the chemical formula BaTiO3. It is characterized by a perovskite structure, which contributes to its high dielectric constant and piezoelectric properties. This material exhibits excellent insulation capabilities and can undergo phase transitions, making it highly responsive to temperature changes.

Structure of pervoskite ABO3 unit cell structure of barium titanate. Singh, Monika & Yadav, Bal & Ranjan, Ashok & Kaur, M. & Gupta, Siddhant. (2016). Synthesis and characterization of perovskite barium titanate thin film and its application as LPG sensor. Sensors and Actuators B: Chemical. 241. 10.1016/j.snb.2016.10.018.

Key properties of Barium Titanate include:

- High Dielectric Constant: Essential for capacitors and other electronic components.

- Piezoelectricity: Ability to generate an electric charge in response to mechanical stress, useful in sensors and actuators.

- Thermal Stability: Maintains performance across a wide range of temperatures.

- Non-linear Optical Properties: Suitable for photonic and electro-optic applications.

Production and Manufacturing

The production of Barium Titanate involves several steps to ensure purity and performance. The primary methods include solid-state reaction, sol-gel process, and hydrothermal synthesis. Each method has its advantages:

-

Solid-State Reaction: This method involves mixing barium carbonate (BaCO3) and titanium dioxide (TiO2) powders, followed by calcination at high temperatures. It is a cost-effective method and suitable for large-scale production but may result in less uniform particle sizes and purity.

-

Sol-Gel Process: This chemical method involves the transition of a solution into a solid gel phase. It offers precise control over the material's properties, including particle size and purity. The sol-gel process allows for the production of highly uniform and pure Barium Titanate, making it ideal for applications requiring high performance.

-

Hydrothermal Synthesis: This method uses high-temperature water under high pressure to dissolve and recrystallize the raw materials. Hydrothermal synthesis provides high purity and uniformity in the final product. It is particularly useful for producing Barium Titanate nanoparticles and other specialized forms of the material.

Here is a concise table summarizing the different production methods for Barium Titanate:

| Production Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Solid-State Reaction | Mixing barium carbonate and titanium dioxide powders, followed by calcination at high temperatures. | Cost-effective, suitable for large-scale production | Less uniform particle sizes and purity |

| Sol-Gel Process | Chemical method involving the transition of a solution into a solid gel phase. | Precise control over properties, highly uniform, and pure | Complex process, higher cost |

| Hydrothermal Synthesis | Uses high-temperature water under high pressure to dissolve and recrystallize raw materials. | High purity and uniformity, ideal for nanoparticles | Requires specialized equipment, can be costly |

Quality control is critical in the manufacturing process to meet industry standards. This includes rigorous testing for dielectric properties, purity levels, and structural integrity to ensure the material performs as required in various applications.

Applications of Barium Titanate

Barium Titanate's unique properties make it suitable for a broad range of applications across various industries:

Electronic Components

Barium Titanate is widely used in the production of various electronic components due to its high dielectric constant and excellent insulation properties:

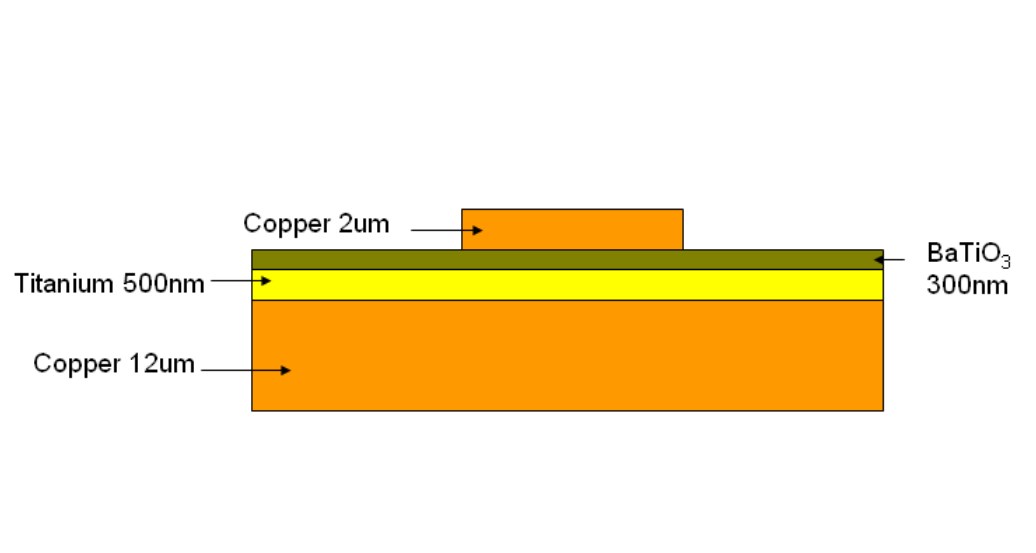

- Capacitors: Barium Titanate is a key material in the manufacturing of capacitors, particularly ceramic capacitors. Its high dielectric constant allows for greater capacitance in a smaller volume, which is essential for miniaturizing electronic devices.

Cross section of a barium titanate capacitor. Muthana, Prathap & Engin, Arif & Pulugurtha, Markondeya & Swaminathan, Madhavan & Tummala, Rao & Sundaram, Venkatesh & Amey, Daniel & Dietz, Karl & Banerji, Sounak. (2006). Design, Modeling and Characterization of Embedded Capacitors for Decoupling Applications.

- Multilayer Ceramic Capacitors (MLCCs): MLCCs are essential in modern electronics, providing stable capacitance across a wide range of frequencies and temperatures. Barium Titanate's properties ensure these capacitors maintain performance and reliability in compact and complex electronic circuits.

- Dielectric Resonators: Used in microwave communication systems, Barium Titanate's dielectric properties enable the production of high-performance resonators that are crucial for signal filtering and frequency stabilization.

- Transducers and Piezoelectric Devices: Barium Titanate's piezoelectric properties make it ideal for use in transducers, which convert electrical signals into mechanical movement and vice versa. This application is crucial in various sensors, actuators, and sound-producing devices.

Industrial Applications

The industrial sector leverages Barium Titanate's piezoelectric properties for precision control and measurement systems:

- Sensors: Barium Titanate is used in pressure, temperature, and acoustic sensors due to its ability to generate an electrical signal in response to mechanical stress. These sensors are vital in monitoring and controlling industrial processes.

- Actuators: In industrial automation, actuators made from Barium Titanate convert electrical signals into precise mechanical movements. This application is essential in robotics, precision machining, and various automated control systems.

- Non-Destructive Testing (NDT): Barium Titanate-based devices are used in NDT to evaluate the integrity of materials and structures without causing damage. This application is important in maintaining safety and quality in the manufacturing, construction, and aerospace industries.

Medical Applications

Barium Titanate's ability to convert mechanical energy into electrical signals enhances its utility in medical technology:

- Medical Imaging Equipment: In ultrasound machines, Barium Titanate transducers generate and receive sound waves, creating detailed images of internal body structures. This capability is crucial for diagnostic imaging in various medical fields.

- Diagnostic Devices: Barium Titanate is used in sensors and diagnostic tools to measure physiological parameters such as blood pressure and heart rate. Its piezoelectric properties ensure high sensitivity and accuracy in these measurements.

- Implantable Medical Devices: Barium Titanate's biocompatibility and electrical properties make it suitable for use in implantable devices, such as pacemakers and defibrillators, which require reliable and long-lasting components.

By leveraging the exceptional properties of Barium Titanate, industries can develop advanced technologies and devices that improve performance, efficiency, and reliability across a wide range of applications.

Advantages and Disadvantages of Barium Titanate

Advantages:

- A high dielectric constant enhances energy storage capabilities.

- Excellent piezoelectric properties for sensors and actuators.

- Thermal stability ensures consistent performance in varying conditions.

- Versatile applications across different industries.

Disadvantages:

- Material brittleness can limit its mechanical applications.

- Production methods can be complex and costly.

- Sensitivity to environmental factors such as humidity and temperature variations.

Buying Barium Titanate

When purchasing Barium Titanate, consider the following factors to ensure you get the best quality for your needs:

- Purity and Composition: Verify the material's purity levels and composition to match your specific application requirements.

- Supplier Reputation: Choose reputable suppliers like Advanced Ceramic Materials (ACM) with a track record of delivering high-quality materials.

- Cost Considerations: While cost is a factor, prioritize quality and performance to avoid potential issues in your applications.

Conclusion

Barium Titanate is a critical material with extensive applications in electronics, industry, and medicine. Its unique properties, such as high dielectric constant and piezoelectricity, make it indispensable for various high-performance applications. When buying Barium Titanate, it is essential to consider purity, supplier reputation, and cost to ensure optimal performance. As part of the broader category of Advanced Ceramic Materials (ACM), Barium Titanate exemplifies the innovation and technological advancements in modern material science, driving progress in multiple fields.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity