Yttria vs. Calcia vs. Magnesia: Decoding Stabilized Zirconia Options

Introduction to Zirconia Stabilization

Zirconia, or zirconium dioxide (ZrO2), stands out in the world of advanced ceramics due to its remarkable combination of strength, toughness, and resistance to wear and corrosion. Its unique properties have made it an indispensable material in a wide range of industrial and technological applications, from cutting-edge aerospace components to dental prosthetics, showcasing its versatility and high performance in challenging environments.

However, the full potential of zirconia is hindered by its tendency to undergo phase transitions at varying temperatures. In its pure form, zirconia can exist in three different crystal structures: monoclinic at room temperature, tetragonal at moderate temperatures, and cubic at high temperatures. These phase changes are accompanied by significant volume alterations, which can lead to cracking and mechanical failure, severely limiting the material's practical applications.

To address this vulnerability, the stabilization of zirconia has become a critical step in its utilization. By introducing small amounts of stabilizing oxides, such as yttria (Y2O3), calcia (CaO), and magnesia (MgO), it is possible to maintain the zirconia in a tetragonal or cubic phase at room temperature, effectively preventing the detrimental phase transitions. This process not only enhances the material's mechanical and thermal properties but also expands its applicability across various fields.

Stabilized zirconia combines the toughness and strength of ceramic materials with the thermal and chemical stability required for high-performance applications, making it a cornerstone of modern material science. Through stabilization, zirconia's inherent limitations are overcome, unlocking its full potential as a versatile and durable engineering material.

Detailed Analysis of Each Stabilizer

Yttria-Stabilized Zirconia (YSZ)

Historical Development: The development of Yttria-Stabilized Zirconia (YSZ) dates back to the mid-20th century when researchers sought materials that could withstand extreme conditions, particularly in the aerospace and nuclear industries. Yttria was identified as an effective stabilizer due to its ability to maintain zirconia's cubic phase at room temperature, thus enhancing its mechanical properties and thermal stability.

Chemical and Physical Properties: YSZ is characterized by its high ionic conductivity, making it ideal for use in solid oxide fuel cells (SOFCs) and oxygen sensors. The addition of yttria to zirconia leads to the formation of a cubic phase structure that remains stable across a wide temperature range, eliminating the phase transition issue. This stabilization results in improved fracture toughness and resistance to thermal shock. YSZ's density, thermal conductivity, and ionic conductivity are optimized for high-performance applications, contributing to its widespread use.

Manufacturing Processes: YSZ is typically produced using powder metallurgy techniques, which include mixing zirconia powder with yttria, pressing the mixture into shapes, and then sintering at high temperatures. Advanced manufacturing processes such as chemical vapor deposition (CVD) or physical vapor deposition (PVD) can also be used to create thin films of YSZ for specific applications like thermal barrier coatings.

Calcia-Stabilized Zirconia (CSZ)

Historical Development: Calcia as a stabilizer for zirconia emerged as a cost-effective alternative to yttria, providing good thermal stability and resistance to thermal shock. It has been used since the late 20th century, primarily in refractory materials and other industrial applications where high temperature resistance is essential.

Chemical and Physical Properties: Calcia-Stabilized Zirconia (CSZ) exhibits a mix of cubic and tetragonal phases, depending on the calcia content. This mixed-phase structure offers good thermal stability and mechanical properties, though generally not to the level of YSZ. CSZ's thermal conductivity is lower than that of YSZ, making it suitable for applications where insulation is key. Its ionic conductivity, while lower than YSZ's, is sufficient for certain types of electrochemical applications.

Manufacturing Processes: Similar to YSZ, CSZ is produced through powder metallurgy, involving the mixing of zirconia with calcia, forming, and sintering. The sintering temperature and time are critical factors in achieving the desired phase composition and properties. Additives can be used to enhance sintering and the final material properties.

Magnesia-Stabilized Zirconia (MSZ)

Historical Development: The use of magnesia as a stabilizing agent in zirconia was explored for its potential to improve the material's resistance to thermal shock and its mechanical strength. Magnesia-Stabilized Zirconia (MSZ) has found applications in environments where both high temperature performance and durability are required.

Chemical and Physical Properties: MSZ is typically stabilized in the tetragonal phase, which provides a good balance between mechanical strength and thermal stability. It has moderate thermal conductivity and ionic conductivity compared to YSZ and CSZ. The addition of magnesia helps to improve the material's resistance to low-temperature degradation, a phenomenon that can affect the longevity and performance of zirconia-based components.

Manufacturing Processes: The manufacturing process for MSZ is similar to that of YSZ and CSZ, with the primary difference being the type of stabilizer used. Powder metallurgy is the most common method, with careful control over the mixing, forming, and sintering processes to ensure the desired properties. Innovations in manufacturing, such as the use of nanopowders and novel sintering techniques, have further enhanced the performance of MSZ.

Below is a table providing a concise overview of the three types of stabilized zirconia, encapsulating the essence of their development, key properties, and production methods.

|

Stabilizer Type |

Historical Development |

Chemical and Physical Properties |

Manufacturing Processes |

|

Yttria-Stabilized Zirconia (YSZ) |

Developed in the mid-20th century for high-performance applications. |

High ionic conductivity, stability across a wide temperature range, improved fracture toughness. |

Powder metallurgy, pressing, sintering, advanced techniques like CVD/PVD for coatings. |

|

Emerged as a cost-effective alternative, used primarily in refractory materials. |

Mix of cubic and tetragonal phases, good thermal stability, slightly higher thermal conductivity than YSZ. |

Similar to YSZ, involving mixing zirconia with calcia, forming, and sintering. |

|

|

Magnesia-Stabilized Zirconia (MSZ) |

Explored for its potential to improve thermal shock resistance and mechanical strength. |

Typically stabilized in the tetragonal phase, moderate thermal conductivity, improved resistance to low-temperature degradation. |

Powder metallurgy process, with careful control over mixing, forming, and sintering phases. |

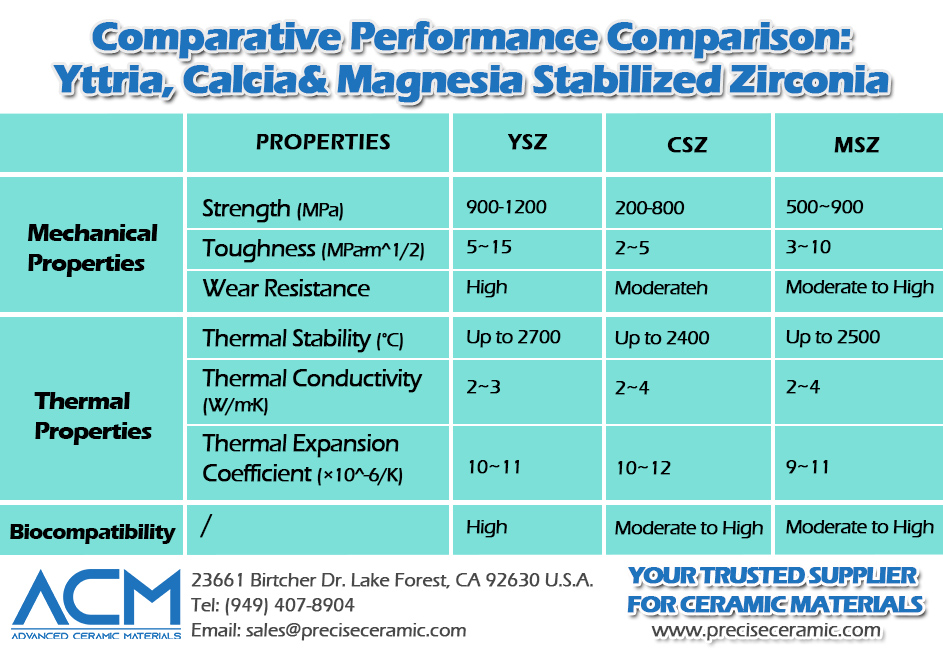

Comparative Performance Analysis

The stabilization of zirconia using yttria, calcia, and magnesia significantly influences its mechanical and thermal properties, as well as its biocompatibility, making each variant uniquely suited to specific applications. This comparative analysis delves into these aspects to highlight the distinctions and potential applications of each stabilized zirconia type.

Mechanical Properties

Strength and Toughness: Yttria-stabilized zirconia (YSZ) is renowned for its exceptional strength and toughness, attributed to the transformation toughening mechanism. This makes YSZ ideal for high-load bearing applications, such as dental implants and cutting tools. Calcia-stabilized zirconia (CSZ), while offering good strength, tends to have slightly lower toughness compared to YSZ, limiting its use in applications where mechanical load and wear resistance are critical. Magnesia-stabilized zirconia (MSZ) provides a balance between strength and toughness, suitable for structural ceramics and refractory materials where moderate mechanical properties are sufficient.

Wear Resistance: YSZ exhibits superior wear resistance due to its high hardness and strength, making it the material of choice for components subjected to abrasive conditions. CSZ and MSZ, although durable, do not match the wear resistance of YSZ, primarily due to their lower hardness and, in the case of CSZ, a greater susceptibility to grain pullout.

Generalized Mechanical Properties Table

|

Property |

YSZ |

CSZ |

MSZ |

|

Strength (MPa) |

900-1200 |

200-800 |

500-900 |

|

Toughness (MPa·m^1/2) |

5-15 |

2-5 |

3-10 |

|

Wear Resistance |

High (Best among the three) |

Moderate |

Moderate to High |

Thermal Properties

Thermal Stability: All three stabilizers improve the thermal stability of zirconia, but YSZ stands out for its ability to withstand higher temperatures without degradation, making it suitable for thermal barrier coatings in jet engines and gas turbines. CSZ and MSZ also offer good thermal stability but are more commonly used in applications with lower temperature thresholds.

Thermal Conductivity and Expansion Coefficients: YSZ has a relatively low thermal conductivity, which is advantageous in thermal barrier applications. It also has a thermal expansion coefficient closely matched to that of metal alloys, facilitating its use in metal-ceramic joints. CSZ has a slightly higher thermal conductivity than YSZ, making it less ideal for thermal insulation but useful in refractories where heat distribution is necessary. MSZ's thermal conductivity is similar to CSZ's, but it offers better thermal shock resistance due to its moderate thermal expansion coefficient.

Generalized Thermal Properties Table

|

Property |

YSZ |

CSZ |

MSZ |

|

Thermal Stability (°C) |

Up to 2700 |

Up to 2400 |

Up to 2500 |

|

Thermal Conductivity (W/m·K) |

2-3 |

2-4 |

2-4 |

|

Thermal Expansion Coefficient (×10^-6/K) |

10-11 |

10-12 |

9-11 |

Biocompatibility

Medical Applications: Biocompatibility is a critical factor for materials used in medical applications. YSZ is highly biocompatible, with minimal ion release, making it suitable for dental and orthopedic implants. Its aesthetic translucency also makes it preferred for dental applications where cosmetic appearance is important. CSZ is used less frequently in direct contact with biological tissues due to concerns about calcium ion release over time, which could affect long-term stability and tissue response. MSZ, while generally biocompatible, is less studied in medical applications compared to YSZ but holds potential for specific applications where its mechanical properties and stability are beneficial.

Generalized Biocompatibility Table

|

Material Type |

Biocompatibility |

Common Medical Applications |

|

YSZ |

High |

Dental implants, hip and knee replacements, other bone implants. High aesthetic quality makes it preferred for visible applications like dental crowns. |

|

CSZ |

Moderate to High |

Limited direct tissue contact applications. Primarily used in medical tools and devices where prolonged tissue exposure is minimal. |

|

MSZ |

Moderate to High |

Emerging applications in bone implants and dental applications, though less common than YSZ. Research ongoing for broader medical uses. |

In summary, the choice between yttria, calcia, and magnesia-stabilized zirconia depends on the application's specific requirements for mechanical strength, wear resistance, thermal stability, and biocompatibility. YSZ offers the best overall performance in high-wear, high-temperature, and biomedical applications, while CSZ and MSZ are more suited to specific niches where their unique properties can be leveraged effectively. Understanding these differences is crucial for material scientists and engineers in selecting the appropriate stabilized zirconia for their specific application needs.

Application-Specific Insights

The diverse properties of yttria, calcia, and magnesia-stabilized zirconia have tailored them for specific uses across various sectors, from aerospace and automotive to energy and medical devices. Each variant’s unique attributes cater to the rigorous demands of these applications, showcasing their pivotal roles in advancing technology and improving life quality.

Aerospace and Automotive

In the aerospace and automotive industries, the high temperature and wear resistance of yttria-stabilized zirconia (YSZ) are invaluable. YSZ’s exceptional thermal stability and low thermal conductivity make it an ideal material for thermal barrier coatings on turbine blades and engine components. These coatings significantly enhance the efficiency and lifespan of engines by allowing higher operating temperatures while protecting underlying metal parts from heat damage. Furthermore, YSZ’s ionic conductivity at high temperatures is leveraged in oxygen sensors, crucial for optimizing fuel combustion and reducing emissions in automotive engines.

Calcia-stabilized zirconia (CSZ) finds its niche in less demanding thermal environments within automotive and aerospace applications, such as insulating layers or components in exhaust systems where cost-effectiveness is a priority over the extreme performance provided by YSZ.

Magnesia-stabilized zirconia (MSZ), with its good thermal shock resistance, is suited for components that undergo rapid temperature changes, offering durability and stability in aerospace materials and automotive sensors that monitor critical engine and exhaust parameters.

Energy Sector

The energy sector benefits significantly from the advancements in stabilized zirconia materials, particularly in solid oxide fuel cells (SOFCs) and battery technologies. YSZ’s high ionic conductivity makes it an excellent electrolyte in SOFCs, facilitating the efficient transport of oxygen ions at high temperatures and contributing to the cell’s overall efficiency and longevity. This property is crucial for developing clean and sustainable energy solutions.

CSZ and MSZ, while not as commonly used in SOFCs as YSZ, have potential applications in other energy technologies, including as components in batteries and energy storage systems where their stability and durability can be advantageous.

Medical Devices

The biomedical sector has seen significant benefits from the use of stabilized zirconia, particularly YSZ, in implants and prosthetics. The high strength, toughness, and excellent wear resistance of YSZ, combined with its exceptional biocompatibility, make it an ideal material for hip and knee replacements. Its aesthetic qualities, resembling the natural color of teeth, have also made YSZ a popular choice in dental implants and crowns, where both durability and appearance are critical.

Calcia and magnesia-stabilized zirconia are less prevalent in direct-contact medical applications due to their slightly lower biocompatibility compared to YSZ. However, their mechanical properties and cost-effectiveness make them suitable for specialized medical tools and equipment where direct long-term contact with body tissues is not a concern.

Across these diverse applications, the choice of stabilized zirconia material hinges on a delicate balance between mechanical performance, thermal properties, biocompatibility, and aesthetic considerations. The ongoing research and development in material science continue to expand the possibilities for these materials, driving innovations that further leverage their unique properties in solving complex challenges across various industries.

Future Trends and Research Directions

The evolving landscape of material science, particularly in the domain of stabilized zirconia, hints at a future ripe with innovation and new applications. As researchers continue to explore and refine stabilization techniques, the emergence of novel stabilizers and composite materials is poised to further enhance the properties and applicability of stabilized zirconia.

Innovations in Stabilization Techniques

Current research is increasingly focused on developing new stabilizers that can offer improved thermal stability, mechanical strength, and biocompatibility. Innovations include the investigation of rare earth oxides beyond yttria, such as scandia, which has shown promise in enhancing the ionic conductivity and thermal stability of zirconia for fuel cell applications. Additionally, composite materials that combine zirconia with other ceramics or metals are being explored to create materials with tailored properties for specific applications, such as improved toughness or electrical conductivity.

Advanced Applications

The future of stabilized zirconia in nanotechnology is particularly exciting, with potential applications in nano-sized sensors and actuators that could revolutionize electronics, environmental monitoring, and healthcare. In electronics, the high ionic conductivity of certain stabilized zirconia materials offers opportunities for developing more efficient and compact solid-state ionics devices.

Advanced manufacturing processes, such as 3D printing and additive manufacturing, are also being adapted to work with stabilized zirconia, opening up new possibilities for complex, custom-designed components in aerospace, automotive, and medical devices. This technology enables the production of parts with intricate geometries that were previously impossible or too costly to manufacture, significantly expanding the scope of applications for stabilized zirconia.

As research continues to push the boundaries of what is possible with stabilized zirconia, these innovations and applications promise to lead to breakthroughs in materials science. The exploration of novel stabilizers, the development of composite materials, and the integration of zirconia into nanotechnology and advanced manufacturing processes are set to redefine the role of this versatile ceramic in the modern world.

Environmental Impact and Sustainability

The manufacturing and disposal of stabilized zirconia, while crucial for various high-tech and medical applications, also pose environmental challenges. The production process, involving high-temperature sintering and the use of potentially hazardous stabilizing agents, can lead to significant energy consumption and the emission of greenhouse gases. Furthermore, the disposal of zirconia-based products, especially those not biodegradable, raises concerns about landfill space and potential soil and water contamination.

Efforts to mitigate the environmental impact of stabilized zirconia are focusing on recycling and reducing the materials' overall footprint. Recycling of zirconia from used products, such as dental crowns and industrial components, is becoming more common. This process involves collecting the used zirconia, crushing it into powder, and then repurposing it for new products, thereby conserving raw materials and reducing waste. However, the recycling process itself must be carefully managed to minimize energy use and avoid releasing harmful substances.

Research is also underway to develop more sustainable manufacturing processes. This includes the exploration of lower-temperature sintering techniques, which can significantly reduce energy consumption. Additionally, there is interest in finding more eco-friendly stabilizers that do not compromise the material's properties but are less harmful to produce and dispose of.

As the demand for stabilized zirconia continues to grow, these efforts to enhance its sustainability are crucial. By improving recycling methods and developing greener manufacturing processes, the material science community aims to ensure that the benefits of stabilized zirconia can be enjoyed without compromising environmental health.

Conclusion

The exploration of yttria, calcia, and magnesia-stabilized zirconia reveals the material's unparalleled versatility and potential across diverse applications. Each variant, from YSZ's exceptional mechanical and thermal properties to CSZ and MSZ's unique balances of cost-effectiveness and performance, offers distinct advantages tailored to specific industry needs. The choice of stabilizer significantly impacts the zirconia's properties, underscoring the importance of selecting the right material for optimizing performance in sectors such as aerospace, automotive, energy, and medical devices.

In this context, the role of companies like Advanced Ceramic Materials (ACM) is crucial. As a leading supplier of advanced ceramic materials, including stabilized zirconia variants, they play a pivotal role in bridging the gap between research findings and real-world applications. By providing high-quality materials that meet the specific requirements of diverse industries, Advanced Ceramic Materials enables innovation and supports the development of cutting-edge technologies.

The journey of stabilized zirconia, from its origins to its current and future applications, highlights the importance of continuous innovation and collaboration between material suppliers, researchers, and engineers. ACM, with its focus on supplying a wide range of advanced ceramics, is instrumental in ensuring that the benefits of stabilized zirconia can be fully leveraged across technological advancements while minimizing environmental impact. This partnership between industry and science is key to harnessing the full potential of stabilized zirconia, paving the way for new discoveries and applications that will shape the future of material science.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments