AlN vs BN-AlN vs BeO: Thermal Conductivity Comparison

Thermal conductivity is a critical property in materials used for high-performance applications such as electronics, aerospace, and industrial thermal management systems. Efficient heat dissipation is essential to maintain performance and longevity in these applications, making the choice of material paramount. Among the leading materials for high thermal conductivity are Aluminum Nitride (AlN), Boron Nitride-Aluminum Nitride composites (BN-AlN), and Beryllium Oxide (BeO). Each of these materials offers unique properties that make them suitable for specific applications. This article will compare their thermal conductivity, exploring their advantages and limitations to guide material selection for various high-performance uses.

Material Properties

Aluminum Nitride (AlN)

Aluminum Nitride (AlN) is renowned for its high thermal conductivity, typically around 170-200 W/m·K. It also possesses a low coefficient of thermal expansion, excellent electrical insulation properties, and good mechanical strength. These characteristics make AlN a preferred material for electronic substrates and heat sinks. Moreover, AlN is non-toxic, which adds to its desirability for applications in the electronics and semiconductor industries.

Boron Nitride-Aluminum Nitride (BN-AlN)

Boron Nitride-Aluminum Nitride composites (BN-AlN) combine the desirable properties of both BN and AlN. Boron Nitride (BN) is known for its excellent thermal stability and electrical insulation, while AlN offers high thermal conductivity. The resulting composite material can exhibit enhanced thermal conductivity and mechanical properties compared to pure BN, while also benefiting from the high thermal conductivity of AlN. This combination can be tailored to specific applications, providing a balance of thermal and mechanical performance.

Beryllium Oxide (BeO)

Beryllium Oxide (BeO) is another material known for its exceptional thermal conductivity, ranging from 260 to 300 W/m·K. BeO also offers high mechanical strength and good electrical insulation properties. However, it comes with significant health hazards due to its toxicity, requiring careful handling and specific safety measures. Despite these challenges, BeO is used in applications where its superior thermal performance is crucial, such as in high-power electronic devices and aerospace components.

Thermal Conductivity Comparison

Methods of Measuring Thermal Conductivity

Thermal conductivity is typically measured using techniques such as the laser flash method, steady-state method, and transient hot-wire method. Each method has its advantages and limitations, and the choice of method can affect the measured values. Consistent and accurate measurement techniques are essential for comparing materials fairly.

Comparative Data and Analysis

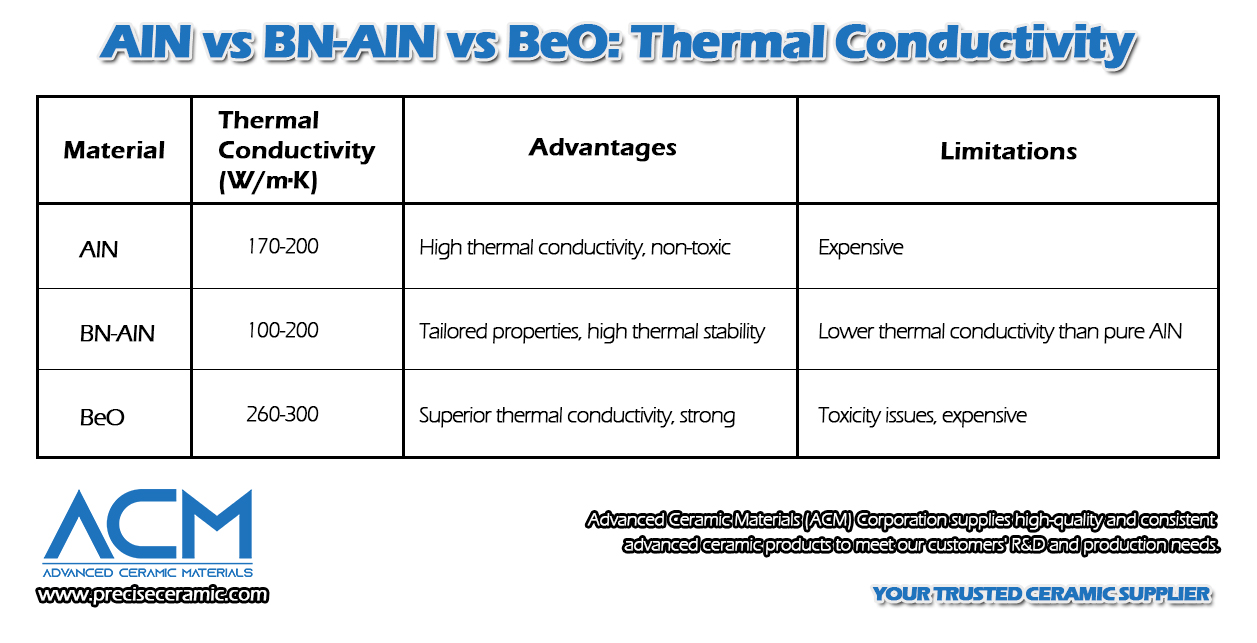

The following table provides a comparative overview of the thermal conductivity of AlN, BN-AlN, and BeO:

- Aluminum Nitride (AlN): With a thermal conductivity of 170-200 W/m·K, AlN is highly effective for heat dissipation in electronic devices. Its low thermal expansion reduces the risk of thermal stress and damage in components subjected to temperature variations.

- Boron Nitride-Aluminum Nitride (BN-AlN): The thermal conductivity of BN-AlN composites can vary widely depending on the composition and manufacturing process. Generally, they exhibit thermal conductivity in the range of 100-200 W/m·K, offering a balance of thermal and mechanical properties.

- Beryllium Oxide (BeO): BeO stands out with its thermal conductivity of 260-300 W/m·K, making it one of the most effective materials for heat dissipation. However, its toxicity requires stringent safety protocols, limiting its use to applications where its superior thermal performance outweighs the health risks.

Applications

Electronics

- Aluminum Nitride (AlN): Used in substrates for power electronics, LED packages, and microwave device packaging due to its high thermal conductivity and electrical insulation.

- Boron Nitride-Aluminum Nitride (BN-AlN): Ideal for applications requiring a combination of thermal conductivity and mechanical stability, such as in thermal interface materials and high-performance electronic substrates.

- Beryllium Oxide (BeO): Employed in high-power electronic devices, RF circuit boards, and semiconductor bases where maximum heat dissipation is critical.

Aerospace

- Aluminum Nitride (AlN): Utilized in components requiring thermal management and structural stability at high temperatures.

- Boron Nitride-Aluminum Nitride (BN-AlN): Suitable for lightweight, thermally stable components in aerospace systems.

- Beryllium Oxide (BeO): Used in aerospace applications where extreme thermal conductivity and mechanical strength are needed despite the toxicity concerns.

Industrial

- Aluminum Nitride (AlN): Used in high-temperature furnace linings and heat sinks in industrial processes.

- Boron Nitride-Aluminum Nitride (BN-AlN): Applied in thermal management systems requiring durable and thermally efficient materials.

- Beryllium Oxide (BeO): Found in high-temperature insulation and thermal management systems where its thermal properties are essential despite handling challenges.

Case Studies or Examples

-

LED Packaging (AlN)

- Example: AlN substrates are widely used in high-brightness LED packages to manage heat dissipation, ensuring longer life and consistent performance.

- Performance: High thermal conductivity of AlN effectively dissipates heat, maintaining LED performance and longevity.

-

Thermal Interface Materials (BN-AlN)

- Example: BN-AlN composites are used in thermal interface materials for processors and high-performance computing systems.

- Performance: The tailored thermal and mechanical properties of BN-AlN improve heat transfer efficiency and system reliability.

-

High-Power RF Devices (BeO)

- Example: BeO is used in high-power RF device substrates where its superior thermal conductivity ensures efficient heat dissipation.

- Performance: Despite handling challenges, BeO’s thermal performance justifies its use in critical applications, providing reliable thermal management.

Conclusion

In summary, AlN, BN-AlN, and BeO each offer unique advantages in thermal conductivity and are suited for specific high-performance applications. AlN is a versatile, non-toxic option with high thermal conductivity, making it suitable for electronics and industrial uses. BN-AlN composites provide a balance of thermal and mechanical properties, ideal for applications requiring tailored performance. BeO, with its exceptional thermal conductivity, remains a top choice for critical applications despite its handling challenges.

The selection of the right material depends on the specific requirements of the application, balancing thermal performance, safety, and cost. Advanced Ceramic Materials (ACM) play a crucial role in pushing the boundaries of thermal management solutions, offering innovative and highly efficient materials for the ever-evolving demands of modern technology. By leveraging the unique properties of these advanced ceramics, industries can achieve superior performance, reliability, and longevity in their thermal management systems.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments