Silicon Monoxide vs. Traditional Silicon: Which Is Better for Semiconductors

The semiconductor industry relies heavily on the materials used in manufacturing. These materials directly impact the performance, efficiency, and longevity of electronic devices. For many years, traditional silicon has been the preferred choice for semiconductor manufacturing. This preference is due to its excellent electrical properties and its abundance. However, a newer material, silicon monoxide (SiO), is now attracting attention. Researchers are studying its potential as an alternative to silicon for specific uses. This article compares silicon monoxide and traditional silicon to see which is better for future semiconductors.

Overview of Traditional Silicon

Silicon in Semiconductors

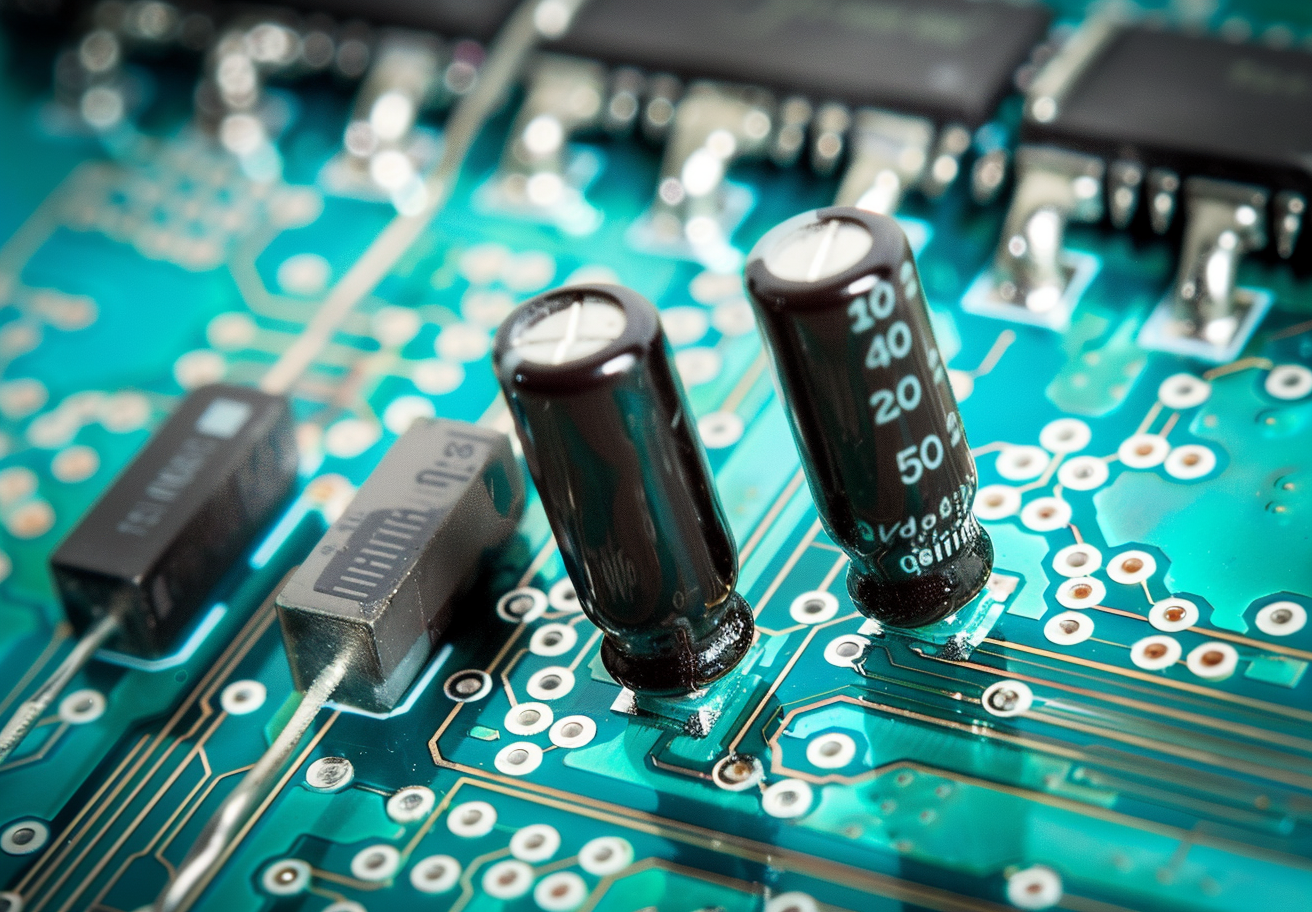

Silicon is the most widely used material in the semiconductor industry. Its role is fundamental to the operation of many electronic devices. The reason for this is silicon's unique electrical properties. Silicon has a 1.1 eV bandgap, which allows it to conduct electricity under certain conditions and act as an insulator under others. This makes silicon perfect for transistors, diodes, and integrated circuits, the foundations of modern electronics.

Properties of Silicon

Besides its electrical properties, silicon is valued for its physical traits. It is the second most abundant element in the Earth's crust, making it inexpensive. Silicon is also easy to process, refined into wafers that form the base of most semiconductor devices. These wafers are made through well-established processes, including cutting, polishing, and doping with other elements to change silicon's electrical properties. This process is vital for making semiconductors used in CPUs, GPUs, memory chips, and solar cells. Silicon's availability and ease of processing have cemented its dominance in the semiconductor industry.

Introduction to Silicon Monoxide (SiO)

What is Silicon Monoxide?

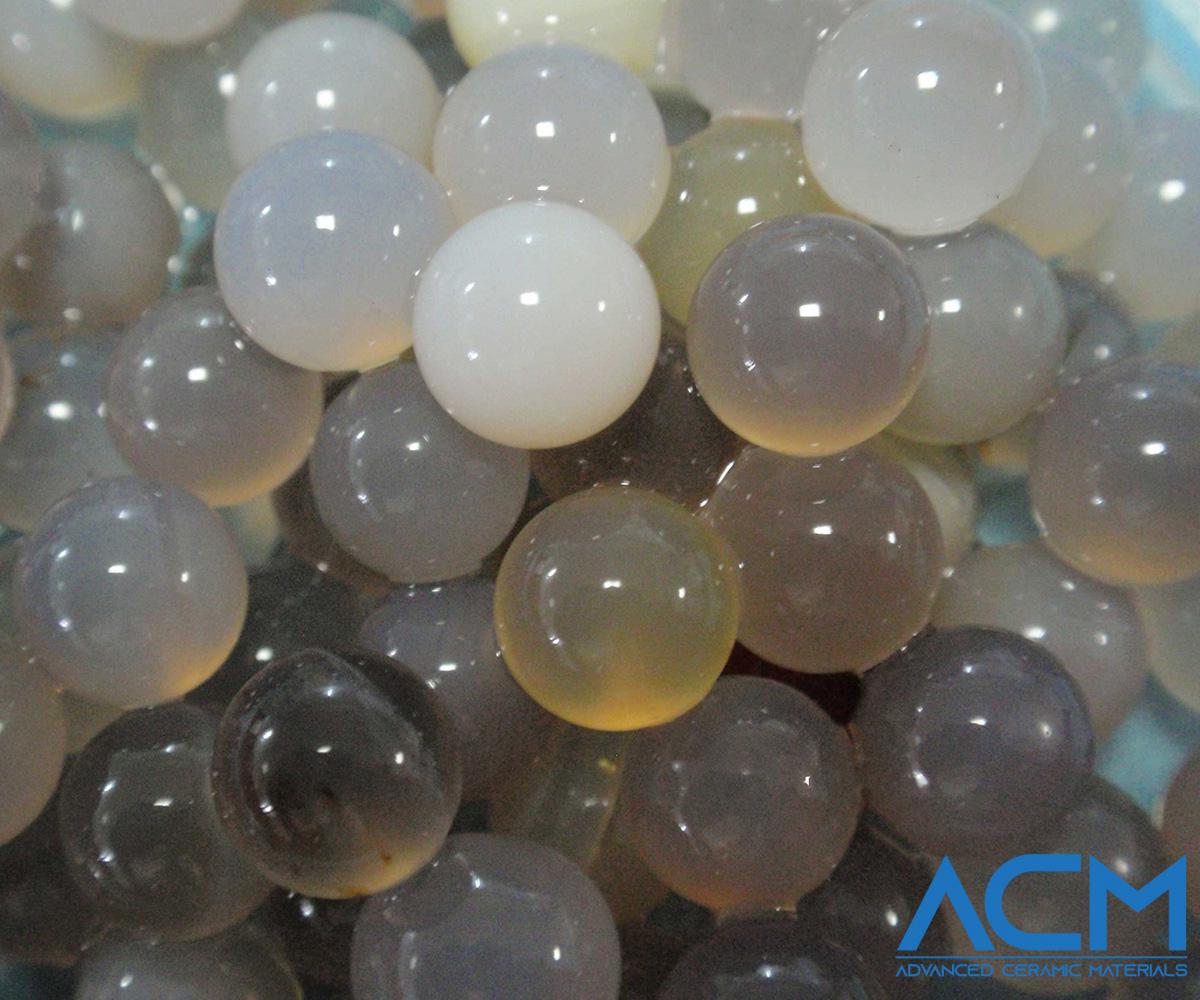

Silicon monoxide (SiO) is made of silicon and oxygen. Unlike silicon's usual crystalline structure, SiO is typically amorphous, with atoms arranged randomly. This structure gives SiO unique properties different from traditional silicon. Discovered in the early 20th century, SiO has been studied for various uses, such as thin films and optical coatings. More recently, researchers have explored its potential in the semiconductor industry.

Historical Background

Although silicon monoxide is not as widely used as traditional silicon, its promising properties make it valuable for specialized applications. One key feature is its ceramic nature, which, combined with high dielectric strength, makes SiO useful in situations where traditional silicon may fall short.

For instance, SiO is preferred in environments requiring high thermal stability or wear resistance. Additionally, SiO is often used in thin films as a protective layer in electronic applications. SiO film can enhance the durability and lifespan of devices.

Comparative Analysis: Silicon Monoxide vs. Traditional Silicon

Electrical Properties

Traditional silicon is well-known for its stability and reliability. These characteristics make it an excellent choice for a wide range of semiconductor applications. Additionally, silicon's consistent bandgap and electron mobility allow for precise control over the flow of electricity within devices. This is essential for the efficient operation of electronic components.

In contrast, silicon monoxide is less established in semiconductors, but it shows potential in specific areas. One of the notable properties of SiO is its high dielectric strength. This makes it a strong candidate for use as an insulating layer in microelectronics. In applications where high-voltage or high-frequency performance is required, SiO could potentially outperform silicon by providing better insulation and reducing the risk of electrical breakdown.

Physical and Chemical Properties

Silicon's stability at high temperatures is a key advantage in semiconductors, ensuring that devices function properly even under heat.

However, silicon monoxide offers benefits in material strength. SiO’s ceramic nature enhances durability and resistance to wear, making it ideal for harsh environments. In applications with frequent stress or abrasive conditions, SiO's toughness is a major advantage. Additionally, SiO can form thin, amorphous films that adhere well to various substrates, making it valuable where traditional silicon might struggle, such as in high-abrasion environments or where flexibility is needed.

Applications in Modern Technology

Traditional silicon remains crucial for manufacturing CPUs, GPUs, and other key electronic components. Its well-understood properties and the established infrastructure for silicon production make it a reliable choice for many applications.

Silicon monoxide is beginning to gain attention in certain advanced technology sectors. One area where SiO shows particular promise is in the development of advanced batteries. For example, SiO is being explored as a material for silicon-based anodes in lithium-ion batteries. SiO’s ability to boost energy density and charging speed could lead to major advancements in battery technology. This is crucial as demand for high-performance batteries grows in industries like electric vehicles and consumer electronics. Additionally, SiO is being investigated for use in microcircuits and optical films. In these applications, SiO’s ability to provide superior protection against moisture and physical wear could make it valuable for extending the lifespan and improving the performance of electronic devices.

Advantages and Disadvantages of Silicon Monoxide in Semiconductor Applications

Advantages

Silicon monoxide offers several advantages that make it an attractive option in certain semiconductor applications.

One of the most significant benefits is its potential to improve battery technology. When used in battery anodes, SiO can significantly increase battery capacity, offering up to ten times the energy density of traditional graphite anodes. This makes it highly appealing for high-performance electronics like smartphones, laptops, and electric vehicles.

Beyond batteries, SiO's superior dielectric properties make it valuable in thin-film applications, providing better insulation and protection in microelectronics, which enhances device performance and longevity.

Disadvantages

Despite its advantages, silicon monoxide faces challenges that could limit its widespread use in the semiconductor industry.

One major drawback is the complexity of its processing and manufacturing. Producing uniform, high-quality SiO films for semiconductor applications often requires advanced, costly, and time-consuming techniques compared to those used for traditional silicon. This results in higher production costs, which may hinder its adoption in industries focused on cost efficiency.

Additionally, the limited research and infrastructure for SiO compared to traditional silicon make it less accessible for large-scale use. This lack of widespread adoption, coupled with the need for further research, could slow SiO's integration into mainstream semiconductor manufacturing.

Conclusion

In conclusion, while traditional silicon remains the cornerstone of the semiconductor industry, silicon monoxide offers unique advantages for specialized applications. Its ceramic properties, such as high dielectric strength and durability, make SiO a promising material in areas where traditional silicon may not suffice. As demand for advanced materials grows, particularly in fields like battery technology and microelectronics, silicon monoxide could play a crucial role. Its potential as an advanced ceramic material suggests that it could complement, rather than replace, traditional silicon in the future of semiconductor technology.

For those interested in silicon monoxide materials or custom ceramic products, Advanced Ceramic Materials (ACM) has recently expanded its offerings to include Silicon Oxide. Feel free to contact us for more information or to discuss your specific needs.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments