Ceramic Dielectric Filler Powder for Next-Gen Circuits

Introduction

5G, or the fifth-generation mobile communication standard, is gaining popularity recently. It connects everyone and everything together with higher speeds, super low latency, much reliability, and improved availability. Thanks to these features, 5G is able to bring about the upgradation of the electronic information industry, and there appears a higher demand for high-frequency, high-speed, advanced circuit materials.

This article is going to discuss these ceramic dielectric filler powders used for next-gen circuits. Hope that you can have a better understanding and select suitable ceramic materials for your business or research.

Features of Ceramic Dielectric Filler Powder

Ceramic dielectric filler powder stands out for its dielectric and thermal features.

- Dielectric Strength: Ceramics are inorganic, non-metallic materials that are known for their excellent dielectric properties, including high electrical resistivity, low dielectric constant, and low dissipation factor. Take the case of boron nitride ceramic. It has a dielectric strength of 80 kV/mm and a dielectric constant of 4. Besides, the resistivity of boron nitride exceeds 1013 Ω cm at 25°C, and the dissipation factor is below 0.001.

- Thermal Properties: In addition to these properties, ceramics are known for their high melting points, chemical resistance, and mechanical strength, making them suitable for use in harsh environments. For example, boron nitride ceramics have excellent thermal performance. They can bear high temperatures up to 1800°C and have a thermal conductivity of 300 W/mK. They can also withstand rapid heating and cooling.

Benefits of Ceramic Dielectric Filler Powder

The use of ceramics as dielectric filler powders in next-gen circuits has several advantages.

- Firstly, they can be used to reduce the dielectric constant of the circuit. This can help to decrease the parasitic capacitance between circuit components and improve the performance of the circuit.

- Secondly, ceramics can be applied to improve the thermal stability of the circuit, which is particularly important in high-temperature applications.

- Also, ceramic dielectric filler powder comes with the enhanced mechanical strength of the circuit, which can help to prevent damage from physical stress or vibration.

- Last, the production cost of circuits can be reduced and market competitiveness can be improved since we use lower-price ceramic fillers instead of expensive resins.

Related reading: Which Inorganic Powder Filler Will Win in the 5G Copper Clad Markets?

Types of Ceramic Dielectric Filler Powder

There are several types of ceramics that are suitable for use as dielectric filler powders in circuits.

Alumina, Zirconia, and Titanium Dioxide

Alumina is an excellent insulator and is widely employed in electronic applications. Zirconia is known for its high mechanical strength and thermal stability, while titanium dioxide is used as a dielectric in high-frequency applications.

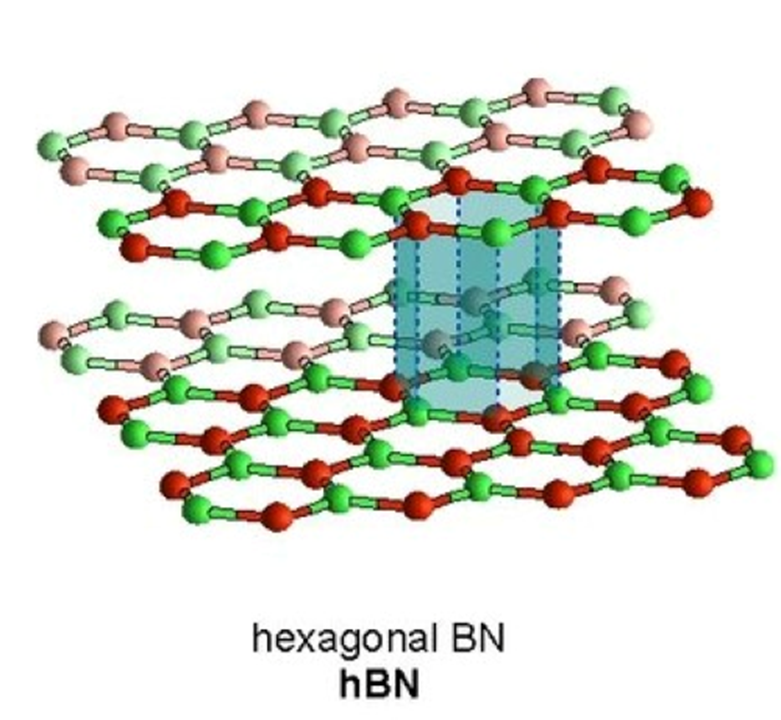

Hexagonal Boron Nitride

Hexagonal boron nitride is another dielectric ceramic material. It is characterized by a low friction coefficient and expansion coefficient, great thermal shock resistance, high strength, and high resistivity and corrosion resistance.

Barium Titanate

Apart from these ceramics, there are also new and emerging ceramics that are being developed specifically for use in electronic applications. For instance, barium titanate is a ceramic material that is currently being studied for use in capacitors and other electronic devices. This material has a high dielectric constant, so it is ideal for use in high-frequency applications.

Strontium Titanate

Another promising ceramic material is strontium titanate. This material has a lower dielectric constant than barium titanate, but it has excellent piezoelectric properties, which make it suitable for use in sensors and other electronic devices.

Conclusion

Overall, the use of ceramics as dielectric filler powders in next-gen circuits has significant potential for improving the performance, thermal stability, and mechanical strength of electronic devices. With ongoing research and development, new and improved ceramic materials will continue to emerge, offering even greater benefits to the electronics industry. As such, it is an exciting time for the use of ceramics in electronic applications.

Advanced Ceramic Materials (ACM) offers a variety of advanced dielectric ceramic materials, including boron nitride, alumina, and zirconia. For more information, please check our homepage.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments