Classification of Ceramic Materials Based on Composition

(i) Silicate ceramics

Silicates are materials generally having a composition of silicon and oxygen. The main types of silicate ceramics are based either on alumosilicates or magnesium silicates. Silicate ceramics are traditionally categorized into coarse or fine and, according to water absorption, into dense (< 2 % for fine and < 6 % for coarse) or porous ceramics (> 2% and > 6 %, respectively).

Further Reading: What are Silicate Ceramics

(ii) Oxide ceramics

Oxide ceramics include alumina, zirconia, silica, aluminium silicate, magnesia and other metal oxide-based materials. These are non-metallic and inorganic compounds by nature that include oxygen, carbon, or nitrogen. Oxide ceramics possess the following properties: (a) High melting points (b) Low wear resistance (c) An extensive collection of electrical properties These types of ceramics are available with a variety of special features. For example, glazes and protective coatings seal porosity, improve water or chemical resistance, and enhance joining to metals or other materials. Oxide ceramics are used in a wide range of applications, which include materials and chemical processing, radiofrequency and microwave applications, electrical and high voltage power applications and foundry and metal processing. Aluminium oxide (Al2O3) is the most important technical oxide ceramic material. This synthetically manufactured material consists of aluminium oxide ranging from 80 % to more than 99 %.

(iii) Non-Oxide ceramics

The use of non-oxide ceramics has enabled extreme wear and corrosion problems to be overcome, even at high temperatures and severe thermal shock conditions. These types of ceramics find their application in different spheres such as pharmaceuticals, oil and gas industry, valves, seals, rotating parts, wear plates, location pins for projection welding, cutting tooltips, abrasive powder blast nozzles, metal forming tooling etc.

(iv) Glass-ceramics

These are basically polycrystalline materials manufactured through the controlled crystallization of base glass. Glass-ceramic materials share many common characteristics with both glasses and ceramics. Glass-ceramics possess an amorphous phase and more than one crystalline phase. These are produced by a controlled crystallization procedure. Glass ceramics hold the processing advantage of glass and has special characteristics of ceramics.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of different classifications of ceramic materials. If you want to know more about ceramics, we would like to advise you to visit Advanced Ceramic Materials (ACM) for more information.

Further Reading: Types and Applications of All Kinds of Ceramic Materials

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

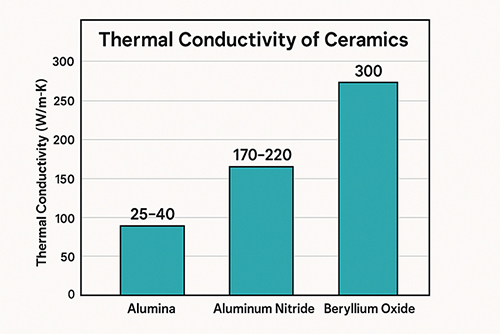

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity