Distinguishing Between LaB6 and Tungsten Filaments in Electron Microscopy

Introduction

Electron microscopy has come a long way since its inception, with advances in technology continually enhancing the ability to observe materials at the nano-level. The choice of filament, serving as the electron source, plays a pivotal role in defining the microscope's performance, affecting everything from resolution to operational efficiency. Among the various options available, tungsten and lanthanum hexaboride (LaB6) filaments stand out due to their distinct properties and applications. Tungsten filaments, known for their durability, are ideal for general microscopy, while LaB6 filaments, with their superior brightness and focus, are favored in high-resolution studies. This article delves into these differences, providing insights that help users in diverse scientific fields—from materials science to biological research—make informed decisions about the best filament for their specific needs in electron microscopy.

Tungsten Filaments

Overview of Filament Types

Tungsten Filaments

Tungsten filaments, made from the metal with the highest melting point of all pure metals (3422°C), are a mainstay in electron microscopy. Their durability and resilience under high temperatures make them an excellent choice for various microscopy setups, including Scanning Electron Microscopes (SEM) and Transmission Electron Microscopes (TEM) , and Microprobe systems. Tungsten's robust properties ensure that it maintains structural integrity and performance consistency even under extreme conditions. These filaments are easy to handle and maintain, making them ideal for educational settings and routine laboratory work where simplicity and cost efficiency are priorities. Despite their widespread use, tungsten filaments have limitations in electron source size and brightness, which can affect the quality of the images produced, especially when finer details are required.

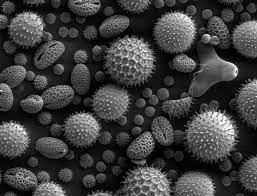

Scanning Electron Microscopy

LaB6 Filaments

Lanthanum Hexaboride (LaB6) filaments are distinguished by their superior electron emission characteristics due to their low work function and high brightness. These properties make LaB6 filaments highly effective for producing sharp, high-resolution images. The small electron source size (approximately 5 μm) allows for a more focused beam, enhancing imaging precision essential for detailed analytical work in nanotechnology and materials science. While LaB6 filaments offer significant advantages in terms of performance, they require a higher degree of technical expertise to handle and maintain. Their use is often reserved for advanced research applications where the highest quality images are necessary. The cost of LaB6, both in terms of initial investment and ongoing maintenance, is higher, but the benefits are clear in settings where cutting-edge technology is critical.

LaB6 Cathode

| Feature | Tungsten Filaments | LaB6 Filaments |

|---|---|---|

| Melting Point | Highest of all pure metals (3422°C) | High |

| Electron Source Size | Larger, less detailed imaging | Smaller (5 μm), detailed imaging |

| Brightness | Standard | High |

| Maintenance | Easy, ideal for routine use | Requires technical expertise |

| Cost | Economical | Higher initial and maintenance costs |

| Typical Applications | Educational, general microscopy | Advanced research, high-resolution microscopy |

| Image Quality | Adequate for general purposes | Superior for detailed analysis |

Comparative Analysis

Electron Source Size and Brightness

The electron source size and brightness are critical for the performance of electron microscopes, with significant implications for image resolution and quality. LaB6 filaments have a marked advantage in this area, offering an electron source size of about 5 μm compared to tungsten's larger 50 μm. This smaller source size allows LaB6 to focus the electron beam more sharply, resulting in higher resolution and better image clarity. Furthermore, the higher brightness of LaB6 enhances the signal-to-noise ratio, providing clearer and more detailed images. These attributes make LaB6 particularly valuable for applications requiring precise imaging, such as semiconductor manufacturing and biotechnological research.

Longevity and Maintenance

LaB6 filaments also excel in longevity, operating effectively for extended periods and thus reducing the frequency of replacements needed. However, this longevity comes with the requirement for meticulous maintenance, including periodic rejuvenation processes like oxygen treatment to maintain optimal performance. On the other hand, tungsten filaments, while not as long-lasting, are easier to replace and maintain. Their simpler maintenance requirements make tungsten a more practical choice in environments where ease of use and lower operational costs are prioritized over maximum performance.

Cost and Usability

In terms of cost-effectiveness, tungsten filaments are more economical, both at the point of purchase and in terms of maintenance. This makes them a popular choice for general microscopy work where high-end performance is not crucial. However, for labs and institutions where cutting-edge research necessitates the best imaging possible, the higher cost of LaB6 filaments is often seen as a worthwhile investment. The usability of each filament type also varies; tungsten's ease of integration into various microscopy systems contrasts with the more specialized requirements for LaB6, necessitating consideration of the laboratory's technical capability and budget.

| Feature | Tungsten Filaments | LaB6 Filaments |

|---|---|---|

| Source Size & Brightness | Larger (50 μm), standard | Smaller (5 μm), higher |

| Longevity & Maintenance | Less durable, easier maintenance | More durable, intensive maintenance |

| Cost & Usability | Economical, easy to use | More expensive, technically demanding |

Conclusion

Choosing the right filament for electron microscopy is a decision that goes beyond simple preference; it entails a strategic evaluation of the specific requirements and constraints of the microscopy work to be undertaken. Tungsten filaments, with their affordability and user-friendliness, are well-suited for general applications where extreme high resolution is not the primary focus. Conversely, LaB6 filaments, known for their superior brightness and smaller electron source size, are indispensable for high-resolution and analytical applications that demand the highest level of detail.

For those looking to source high-quality LaB6 filaments, Advanced Ceramic Materials (ACM) offers a reliable supply of LaB6 ceramics, known for their consistency and superior performance. ACM's expertise in advanced ceramic products ensures that users receive materials that meet the highest standards, crucial for achieving optimal results in precision electron microscopy.

Ultimately, the decision should align with the operational goals, budget constraints, and technical expertise available within the laboratory. By understanding the distinct advantages and practical implications of each filament type, microscopy users are better equipped to make informed choices that optimize the capabilities of their electron microscopes, leading to more successful and insightful scientific investigations.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments