Understanding Ceramic Powder Particle Sizes: Techniques and Applications

Introduction

Ceramic powders play a crucial role in various industries such as electronics, automotive, and biomedical sectors. The particle size of these powders significantly influences their processing and performance characteristics. This article explores the techniques for measuring ceramic powder particle sizes and the importance of these measurements, providing a comprehensive overview for researchers and industry professionals.

Importance of Particle Size in Ceramics

The particle size distribution of ceramic powders affects their properties and behavior during processing and in their final application. Key influences include:

- Densification: Smaller particles can enhance densification during sintering, leading to improved mechanical properties. The ability of a ceramic material to densify uniformly is crucial for achieving high strength and durability in the final product. Inadequate densification can result in weak spots and potential failure points.

- Transport Properties: Particle size affects the flow and mixing behavior, crucial for uniformity in material properties. For instance, finer particles mix more thoroughly with other components, ensuring consistent material characteristics throughout the batch. This uniformity is essential for maintaining the desired electrical and thermal properties in electronic ceramics.

- Mechanical Strength: Uniform particle sizes contribute to consistent mechanical strength and durability. Disparities in particle size can lead to uneven stress distribution under mechanical loads, potentially causing fractures or other structural failures. By controlling particle size distribution, manufacturers can enhance the reliability and lifespan of ceramic products.

- Thermal Stability: Particle size impacts the thermal properties, which are critical in high-temperature applications. Smaller particles tend to have higher surface areas, which can influence the thermal conductivity and heat resistance of the ceramic material. This is particularly important in applications like aerospace and automotive components, where materials are subjected to extreme temperatures and thermal cycling.

Techniques for Measuring Ceramic Powder Particle Sizes

1. Laser Diffraction

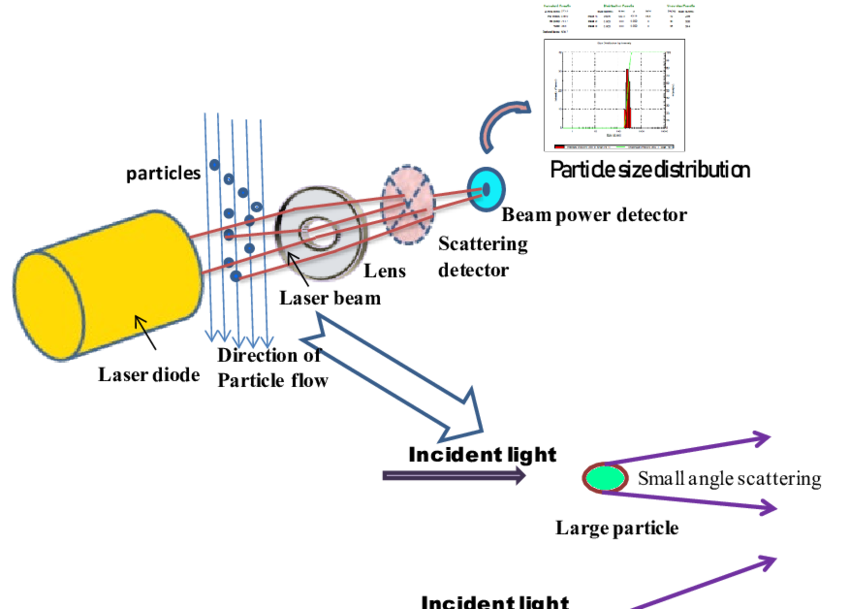

Principle of laser diffraction [1]

Principle: Laser diffraction analyzes the pattern of light scattered by a sample to determine particle size distribution. The angle and intensity of the scattered light provide information on particle sizes. This technique relies on the assumption that particles are spherical, which may not always be accurate for all types of ceramic powders.

Advantages: Suitable for a broad range of particle sizes, from sub-micron to millimeters, and can handle both dry and wet samples. It is fast and highly accurate, making it widely used in various industries. Additionally, it requires relatively simple sample preparation and can process large sample volumes, enhancing its practicality for industrial applications.

Applications: Laser diffraction is commonly used in quality control laboratories and research facilities to ensure consistent particle size distribution in ceramic powders. It is particularly useful in industries where precise particle size control is critical, such as pharmaceuticals and advanced ceramics.

2. Dynamic Light Scattering (DLS)

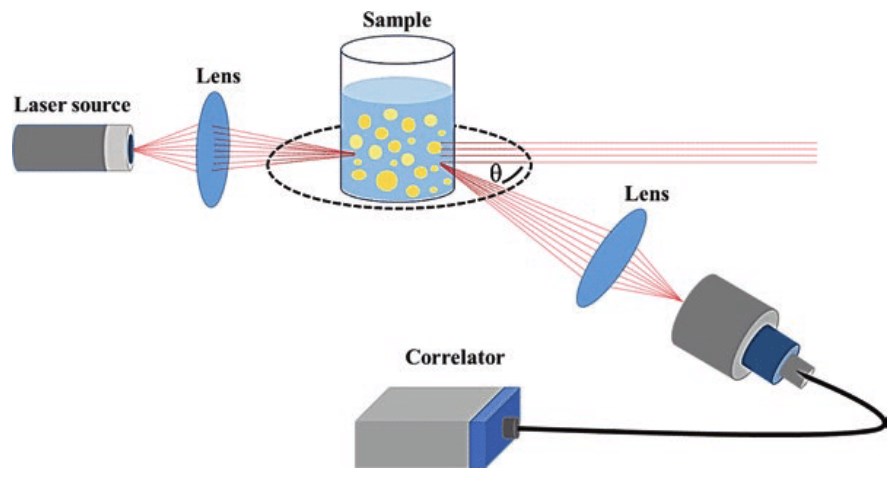

Representation of dynamic light scattering principle. [2]

Principle: DLS measures the Brownian motion of particles in a suspension, with the fluctuation in scattered light intensity used to calculate particle size. This technique is highly sensitive to small particles, making it ideal for analyzing nanoparticles and colloidal dispersions.

Advantages: Ideal for measuring nanoparticles and colloidal dispersions. It offers high-resolution data for small particles, making it particularly useful in research and quality control. DLS can detect subtle changes in particle size distribution, which is beneficial for monitoring processes like particle aggregation or dissolution.

Limitations: Less effective for larger particles or samples with a broad size distribution. The technique also requires a homogeneous suspension, as large particles or aggregates can skew the results. Additionally, DLS is sensitive to contaminants, which can interfere with the accuracy of measurements.

3. Image Analysis

Principle: This method captures images of particles using microscopes and analyzes them with software to determine size and shape. Advanced image analysis techniques can differentiate between particles based on their morphology, providing more detailed information than simple size measurements.

Advantages: Provides detailed information on particle morphology and size distribution. It is useful for applications where particle shape and size uniformity are critical. Image analysis can also identify defects or irregularities in particles, which can affect the performance of the final ceramic product.

Challenges: Requires high-quality imaging systems and can be time-consuming compared to other methods. The accuracy of image analysis depends on the resolution and quality of the images, as well as the sophistication of the analysis software. Manual interpretation may also introduce subjectivity, potentially affecting consistency.

4. Centrifugal Sedimentation

Principle: Uses centrifugal force to separate particles based on size and density. The sedimentation rate helps determine particle size distribution. This technique is particularly effective for fine particles and can provide precise measurements for narrow size distributions.

Advantages: Effective for fine particles and can provide precise measurements for narrow size distributions. It is highly sensitive to small differences in particle size, making it suitable for detailed analysis of fine ceramic powders.

Challenges: Requires careful sample preparation to prevent particle agglomeration, which can affect accuracy. Additionally, the method may be less effective for particles with irregular shapes or broad size distributions. The equipment used for centrifugal sedimentation is also relatively complex and requires regular maintenance to ensure accuracy.

Applications of Particle Size Measurement

Accurate measurement of ceramic powder particle sizes is essential for several applications, including:

- Electronic Ceramics: Ensuring uniform particle sizes can improve the dielectric properties and mechanical strength of electronic components. In applications such as capacitors and insulators, precise control over particle size distribution enhances the performance and reliability of the components. This is crucial for maintaining the stability and efficiency of electronic devices.

- Biomedical Implants: Consistent particle sizes are crucial for the biocompatibility and mechanical integrity of ceramic-based implants. In medical applications, uniform particle size distribution ensures that implants have the desired strength and do not release particles that could cause adverse biological reactions. This consistency is vital for the safety and efficacy of biomedical devices.

- Aerospace Components: Uniform particle distribution enhances the thermal stability and mechanical performance of ceramics used in high-temperature environments. In aerospace applications, materials are subjected to extreme conditions, and any variability in particle size can lead to weaknesses and potential failure. Accurate particle size measurement helps in producing components that meet the stringent requirements of the aerospace industry.

Conclusion

Understanding and accurately measuring ceramic powder particle sizes is vital for optimizing material properties and ensuring quality in various applications. Techniques such as laser diffraction, dynamic light scattering, image analysis, and centrifugal sedimentation offer valuable tools for researchers and industry professionals. Each method has its advantages and specific applications, making it important to choose the appropriate technique based on the particle size range and the nature of the ceramic powder.

Accurate particle size measurement helps achieve desired material characteristics, enhancing ceramic products' performance and reliability across different industries. Advanced Ceramic Materials (ACM) provides advanced solutions and materials, contributing to the continuous improvement of ceramic technologies and their applications in various sectors.

Reference:

[1] Nayak, Smita & Ghugare, Priyanka & Vaidhun, Bhaskar. (2020). EVALUATION OF AERODYNAMIC PARTICLE SIZE DISTRIBUTION OF DRUGS USED IN INHALATION THERAPY: A CONCISE REVIEW. International Journal of Research -GRANTHAALAYAH. 8. 264-271. 10.29121/granthaalayah.v8.i7.2020.579.

[2] Choudhary, R.C. & Kumari, Sarita & R V, Kumaraswamy & Pal, Ajay & Raliya, Ramesh & Biswas, Pratim & Saharan, Vinod. (2019). Characterization Methods for Chitosan- Based Nanomaterials. 10.1007/978-3-030-12496-0_5.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments