Silicon Carbide: Reaction Sintering vs. Pressureless Sintering

Silicon Carbide (SiC) is a material that has gained significant popularity in recent years due to its unique properties, including exceptional hardness, high thermal conductivity, and excellent resistance to corrosion and wear. SiC has a wide range of applications, including in the aerospace, automotive, and energy industries. However, the manufacturing process of SiC is complex and requires specific techniques to ensure that the final product is of high quality. Two popular methods of producing SiC are reaction sintering and pressureless sintering. While both methods have their advantages and disadvantages, choosing the right technique is crucial for achieving the desired properties and quality of the final product. In this article, we will explore the differences between these two methods and provide insights into their respective strengths and weaknesses.

What is Reaction Sintering?

Reaction sintering, or reaction bonding, is a densification process in which reactive liquid silicon or silicon alloy is infiltrated into a carbon-containing porous ceramic body to react to form silicon carbide, and then combined with the original silicon carbide particles to fill the remaining pores in the body.

The specific process is as follows:

1) Mix fine particles of α-SiC and graphite in a certain proportion, and heat it to about 1650°C to make a billet.

2) At high temperatures, the carbon in the green body reacts with the infiltrated Si to form β-SiC, which is combined with the existing α-SiC particles.

3) When Si is completely infiltrated, the remaining pores are filled, so a reaction-sintered body with complete density and no shrinkage in size can be obtained.

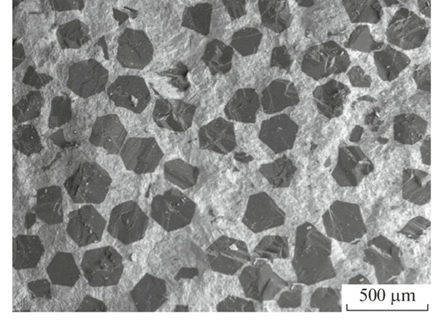

Figure 1. Microstructure of reactive-sintered diamond-silicon carbide material. Kim, Weon-Ju & Kim, Daejong & Park, Jeong Yoon. (2013). Fabrication and material issues for the application of SiC composites to LWR fuel cladding. Nuclear Engineering and Technology. 45. 10.5516/NET.07.2012.084.

Pros and Cons of Reaction Sintered SiC

The process of reaction sintering is advantageous due to its ability to achieve low sintering temperatures and short sintering times while producing near-net shapes. This method is particularly effective for creating large-sized and complex-shaped silicon carbide ceramics. However, there are some challenges associated with reaction sintering, including uneven density and cracking of the final product, and insufficient silicon penetration during sintering. Additionally, this process is not recommended for use in environments that are strongly oxidizing or corrosive.

What is Pressureless Sintering?

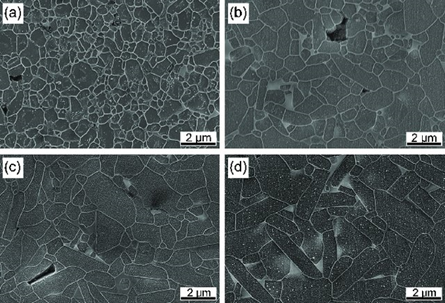

Pressureless sintered silicon carbide ceramics use high-purity, ultra-fine silicon carbide powder as raw material, add a small number of sintering aids, and sinter at a high temperature of 1950~2100°C in an inert gas or vacuum atmosphere at atmospheric pressure. The relative density of SiC ceramics obtained by pressureless sintering is greater than 95% of the theoretical density, and the grains are fine, with an average size of 1.5 μm.

According to different sintering mechanisms, pressureless sintering can be divided into solid-phase sintering and liquid-phase sintering. The sintering aids for solid-phase sintering are usually C and B. B is used for solid solution into silicon carbide to reduce the grain boundary energy of the silicon carbide interface, and C reduces and removes SiO2 at the silicon carbide interface to increase the surface energy. Liquid phase sintering uses one-element or multi-element eutectic oxide (such as Y2O3-Al2O3) as a sintering aid. At a relatively low temperature, the low eutectic point is used to generate a liquid phase to promote the movement, diffusion, and mass transfer of silicon carbide particles, thereby realizing the densification of silicon carbide. Generally speaking, liquid sintering is better than solid sintering because of lower sintering temperature, lower requirements for raw materials, stronger fracture toughness of materials, etc.

Figure 2. Typical microstructures of SiC ceramics sintered at various temperatures for 2 h in argon : (a) 1750°C, (b) 1800°C, (c) 1850°C, and (d) 1900°C. Kim, Hyun-Min & Kim, Young-Wook. (2019). Low-temperature pressureless sintering of silicon carbide ceramics with alumina–yttria–magnesia-calcia. Journal of the Ceramic Society of Japan. 127. 207-214. 10.2109/jcersj2.19024.

Advantages and Disadvantages of Pressureless Sintering SiC

The silicon carbide products obtained by pressureless sintering are almost completely dense and have excellent mechanical properties. One advantage of this process is that it allows for various forming methods to produce products with diverse shapes, and the application of appropriate additives can lead to high strength and toughness. However, this technique has its drawbacks, such as high sintering temperatures, resulting in porous materials that have relatively low strength and experience approximately 15% shrinkage in volume. Moreover, there is a possibility of uneven chemical composition and density during the sintering process, which can negatively impact the product's uniformity.

Comparison Between Reaction Sintering and Pressureless Sintering

In terms of high-temperature resistance and flexural strength, pressureless sintering silicon carbide is better than SiC obtained by reaction sintering, especially when the temperature exceeds 1400 °C. In addition, the resistance to strong acid and alkali of reaction-sintered SiC ceramics is slightly inferior to that of pressureless sintered SiC. Although pressureless sintering has these advantages over reactive sintering, it requires more expensive silicon carbide powder than reactive sintering, and the manufacturing cost is higher. Furthermore, the use of additives in pressureless sintering may result in increased material porosity.

Conclusion

The two silicon carbide sintering methods have their own advantages. The choice between the two depends on the specific application of your project. If you are unsure about which method to opt for, we are happy to help. We offer both reaction-sintered silicon carbide ceramics and pressureless sintered silicon carbide materials, along with the necessary raw materials for each method.

Advanced Ceramic Materials (ACM) Corporation supplies high-quality and consistent silicon carbide products as well as other advanced ceramics to meet our customers' R&D and production needs. For more information, please visit our homepage.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments