What Are the Abrasive Materials?

What Are Abrasives?

Abrasives are made of extremely hard materials that can be used to process other materials by wearing away the surface of the material to be processed. Abrasive materials are generally harder and more resistant than the surfaces they process. This ensures that the frictional force they create has little effect on them. Abrasives can be produced using both natural and synthetic materials. And the hardest abrasive material known to man is diamond. There are various forms of abrasives, such as grinding wheels, sandpapers, polishes, honing stones, and ball mills. Abrasives are essential in various industries. Without them, most products will lack a smooth and neat surface.

Development and History of Abrasive Materials

Historians believe that abrasives have always been in existence in various cultures and various forms. Perhaps, the crudest use of abrasives can be observed in the rubbing together of two hard stones to shape a weapon. This was practiced by the early men in prehistoric times. Ancient artworks from around the world also point to the fact that abrasives have always been in existence. The earliest record of coated abrasives is a 13th-century Chinese document. This document throws light on how seashells are bound to parchments to create abrasives. Nearly 200 years later, the Swiss started fixing ground glass on parchment. However, as the industrial revolution began to take root, abrasives made from glass and sand could not keep up with the demands of the new industries. Swen Pulson was able to manufacture a grinding wheel by mixing Emery with potter's clay in 1873. This was found to be more efficient than the abrasives in place before then. A breakthrough in the development of abrasive materials took place in 1955. This year, the General Electric Company manufactured the first synthetic diamonds. Today, we have abrasives of varying speed and power. These abrasives can take on several tasks that would have once been considered challenging.

Common Industrial Abrasive Materials

Diamond

Diamond is the hardest material known to man. This makes it ideal as an abrasive material. Diamond grains are fixed on cutting tools to improve their efficiency. Cutting tools made with diamonds have a high wear resistance and long lifespan. However, diamond is an expensive abrasive material.

Aluminum Oxide

Aluminum Oxide is another common abrasive material. It is an extremely hard mineral and produces excellent results when used as an abrasive material. This material is more cost-effective than most other abrasive materials. It also produces little to no dust residues when used on a surface. This is not often the case with other abrasive materials.

Silicon Carbide

Silicon carbide is a sharp and hard abrasive material. It is one of the two most commonly used abrasive materials. The other is aluminum oxide. Silicon carbide is brittle and susceptible to wear. Therefore, it is not durable. This abrasive material is usually ideal for non-metallic and low-tensile strength surfaces.

Further Reading: Silicon Carbide Abrasive Vs. Aluminum Oxide Abrasive

Cubic Boron Nitride

Cubic boron nitride is an excellent abrasive material. It is almost as efficient as diamond and is the second hardest known material. In addition, this abrasive material is stable and can withstand high temperatures. This means that cubic boron nitride can be used for high-speed applications.

Application of Abrasive Materials

Polishing

Abrasive materials are commonly used to polish workpieces. Polishing is an aggressive process that involves using an abrasive to smooth the surface of an object. This process improves the appearance of an object. In addition, it prevents corrosion and oxidation. Commonly polished workpieces include kitchenware, handrails, and architectural metals.

Grinding

Grinding wheels used for grinding are usually made from abrasive materials. They are used as cutting tools. In these cutting tools, each grain of abrasive material acts as a single-point cutting edge. For this reason, grinding is also referred to as abrasive cutting. Further Reading: What Are the Ceramic Materials Used as Grinding Media?

Drilling

Drilling is a process that involves making a hole in a hard surface. It is also considered a cutting process. The drill bit used in making a hole is usually made from abrasive materials. These abrasive materials create the sharp edge necessary for drilling. A wide range of materials can be drilled. These materials include metals, wood, and plastic.

Lapping

Lapping is a process that involves rubbing two surfaces together with an abrasive between them. Lapping is usually used to create an accurate surface texture. This process usually comes after grinding.

Honing

Honing is a process used to improve the geometric form of an object. In this process, an abrasive is scrubbed against metal in a specified path. Hone is the tool used for honing. It is usually made up of abrasive grains held together by an adhesive.

Conclusion

There are numerous abrasive materials, all of which serve important purposes in industrial processes. Each abrasive material has applications it is well-suited for. This means that the right abrasive material must be used for a particular application for optimal results. For more information about advanced materials, please visit https://www.preciseceramic.com/.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

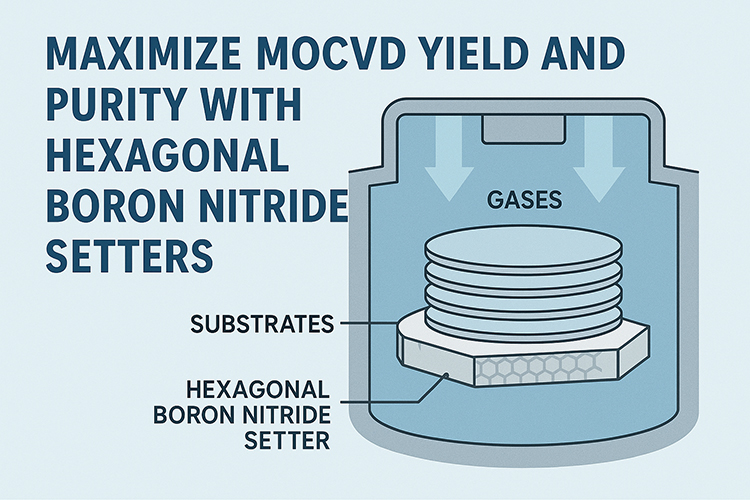

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity