What Does It Take To Make Opaque Ceramics Transparent?

https://www.preciseceramic.com/products/alumina-al2o3.htmlThe ceramic material that everybody sees at ordinary times is opaque normally, so what does it take to make opaque ceramics transparent?

What Are Transparent Ceramics?

Transparent ceramics refer to polycrystalline materials with certain light transmittance prepared by ceramic technology, also known as optical ceramics. Compared with glass or resin optical materials, transparent ceramics are stronger, harder, more resistant to corrosion and high temperatures, and can be used in extremely severe conditions.

Producing high-performance single-crystal optical components requires considerable time and effort as they must be cut from the ingot, which involves a considerable material loss in the processing. High-performance transparent ceramic parts can be produced by the ceramic forming method, which can meet the needs of small batch sample preparation, multi-variety preparation, and mass production.

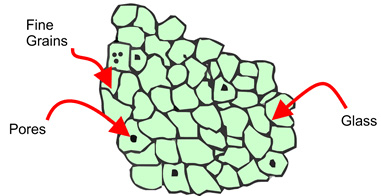

Why Are Ceramics Opaque?

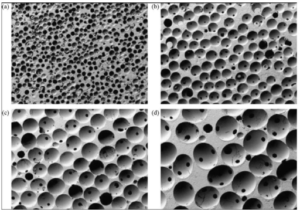

Ceramics is a kind of polycrystalline inorganic material, which is generally composed of grains, grain boundaries, pores and so on. Generally speaking, the opacity of polycrystalline ceramics is caused by the discontinuity of refraction coefficient between grains due to the randomness of arrangement orientation of non-equiaxed (cubic) grains, as well as the scattering caused by grain boundary effect and porosity. The porosity and impurities in the ceramic material can be fully eliminated and the grain size of the ceramic material can be properly controlled to make the product close to the theoretical density through the use of high purity, ultra-fine raw materials, with as few additives as possible and strict process control when preparing ceramics, thus transparent ceramics were prepared. In addition, the primary condition for the preparation of transparent ceramics is that the single crystal that makes up the ceramics is transparent and has high symmetry, generally a cubic crystal system. Some non-cubic ceramic materials such as hexagonal alumina can also be used to produce translucent ceramics under certain conditions.

![]()

The cubic silicon nitride formed under high pressure is slightly inferior in hardness to diamond, and it is the strongest and hardest transparent spinel ceramics that have been prepared so far.

Factors Affecting the Transparency of Ceramics

There are many factors affecting the transparency of ceramics, which involve all aspects of the ceramic preparation process, and the main control factors are the raw material powder, sintering process, ceramic microstructure, and post-treatment process. These factors are often related to each other, and the various influencing factors are summarized below.

1. Effect of raw material powders

* Crystal structure and defects

The crystal structure determines the optical properties of ceramic polycrystals and directly affects their transparency. Polycrystalline ceramics of the cubic crystal system only scatter on the grain boundary, and their transparency is close to that of transparent glass in the visible light region. The crystals of tetragonal, trigonal, and hexagonal systems are uniaxial anisotropic crystals with birefringence and reflection loss at grain boundary interface and low light transmittance. The crystals of monoclinic, triclinic, and orthomorphic systems are biaxial anisotropic crystals. The birefringence and the reflection loss at the grain boundary are more serious, and the light transmittance of corresponding polycrystalline materials is lower or even opaque. In some anisotropic crystals (-alumina), the difference in the main refractive index is very small, and the reflection loss at the grain boundary interface is not enough to seriously affect the transparency, so the crystal still has high transparency. The crystal structure has a great influence on the transparency of polycrystalline ceramics, and the influence of crystal structure defects cannot be ignored. For example, the presence of O2- vacancy in the material is conducive to the diffusion of O2-, which can promote the sintering of oxide transparent ceramics, but the residual oxygen vacancy in the sintered products will reduce the transparency of ceramics. In addition, the dislocations of crystals, growth streaks on the surface of grains, and disordered orientation of crystallization direction are also unfavorable factors to improve the transparency.

* Purity and granularity of raw materials

High purity (99.5% or above), high dispersion, and high sintering active powder are used to prepare transparent ceramics. The impurities in the raw material will generate dissimilar phases and form light scattering centers, which weaken the intensity of the projected light in the incident direction and significantly reduce the transparency of the product. In addition, on the premise of keeping powder particles highly dispersed and high molding density, the smaller the raw material powder is, the more favorable it is for the elimination of porosity and the improvement of sintering performance. But in fact, raw material size has a suitable range. If the particle size of raw materials is too fine, it will lead to low molding density, easy agglomeration, and adsorption of heterogeneous molecules in the environment.

* The dispersion of the material

In addition to high purity and small particle size, the powder should be highly dispersed to ensure high sintering activity. The so-called high dispersion means that the particles can still maintain their independence when the raw material particles reach a certain fineness, and particles do not agglomerate to form larger secondary particles due to their interactions.

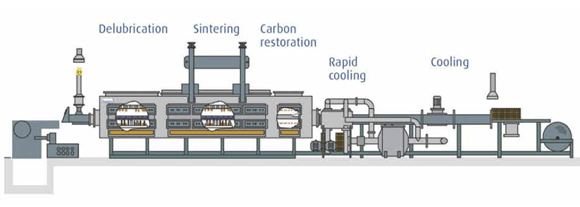

2. Sintering technology

* Gaseous medium

Transparent ceramics differ from ordinary ceramics in that they are finally fired in a vacuum, hydrogen atmosphere, or another atmosphere. The correct choice of gas medium is one of the important conditions for the preparation of transparent ceramics. Sintering in the air or inert gas medium makes it difficult to produce transparent ceramics without pores because air or inert gas remains in the pores, which is not conducive to the elimination of pores. Therefore, it is necessary to sinter by vacuum or using a hydrogen atmosphere. For cationic and anionic compounds with little volatility and little difference, vacuum firing can be used. For example, transparent ceramics such as alumina, yttrium oxide, scandium oxide, and zirconia can be made by vacuum sintering.

* Firing temperature

Transparent ceramics require a higher sintering temperature than ordinary ceramics to remove porosity and achieve transparent sintering. When firing transparent ceramics, the highest firing temperature should be determined according to the properties of sintered materials and the properties and size of the body. The optimum sintering temperature is also related to the bearing capacity of thermal equipment, and energy-saving should be considered at the same time. In conclusion, on the premise of ensuring optical transparency, the firing temperature of transparent ceramics should be as low as possible.

* Sintering additive

On the one hand, sintering additives can effectively reduce sintering temperature; on the other hand, they can inhibit grain boundary migration and grain production, promote porosity elimination, and contribute to sintering densification. However, excessive addition will produce a second phase, which will affect the light transmittance. When determining the amount of additive, it should be ensured that it does not precipitate out in the form of the new solid phase, but completely enters the main crystal phase to form a solid solution.

3. Microstructure of ceramics

* Grain boundary

The grain boundary is one of the most important factors to destroy the optical uniformity of ceramic bodies and causes the scattering of light. The phase composition of ceramic materials usually consists of two or more phases, and such a polyphase structure can easily lead to light scattering on the phase boundary surface. The greater the difference in material composition, the greater the difference in refractive index, and the lower the light transmittance of the whole ceramic. Therefore, the crystal boundary region of transparent ceramics should be thin, have good light matching, no porosity and inclusion, dislocation, and so on. Ceramic materials with isotropic crystals can achieve a linear transmittance close to that of glass.

* Grain size

The crystal size of polycrystalline ceramics also has a great influence on the light transmittance of transparent ceramics. When the wavelength of incident light is equivalent to the diameter of the grain, the scattering effect of light is the largest and the transmittance is the lowest. Therefore, the grain size should be controlled outside the wavelength range of the incident light to improve the transmittance of transparent ceramics.

* Porosity of ceramics

In essence, the preparation process of transparent ceramics completely excludes the densification process of microscopic pores in the sintering process, and the size, number, and type of pores in the material will have a significant impact on the transparency of ceramic materials.

The light transmittance of the material can be significantly changed by a slight change in porosity. For example, studies have shown that when the porosity of closed pores in ceramic bodies changes from 0.25% to 0.85%, the transparency decreases by 33%. Although this may be the result of certain circumstances, we can see to some extent that the effect of porosity on the transparency of ceramics is a direct reflection of violence. Other research data showed that when the stomatal volume accounted for 3%, the light transmittance was 0.01%, and when it was 0.3%, the light transmittance was 10%. Therefore, transparent ceramics must increase the density and reduce the porosity, and the density is usually greater than 99.9%.

4. Surface finish

The transmittance of transparent ceramics is also limited by the surface finish. After sintering, the surface of untreated ceramic has a high roughness and presents a slight concave and convex shape. When light hits this surface, diffuse reflection will occur. The greater the group roughness of sintered ceramics, the lower its transparency.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of transparent ceramics. If you want to know more about ceramics, we would like to advise you to visit Advanced Ceramic Materials (ACM) for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Why Alumina Grinding Balls Are Replacing Steel Across Multiple Industries

- Case Study: Replacing Alumina Tubes with Mg-Stabilized Zirconia to Meet 1850°C Demands

- Case Study: Why 95% Alumina Beats 99% in Thermal Cycling

- Guide to Alumina Grinding Balls: Properties, Applications, and Selection

- Understanding DFARS Compliance: What It Means for Material Sourcing and Why It Matters