How Did Boron Nitride Ceramics Develop Today?

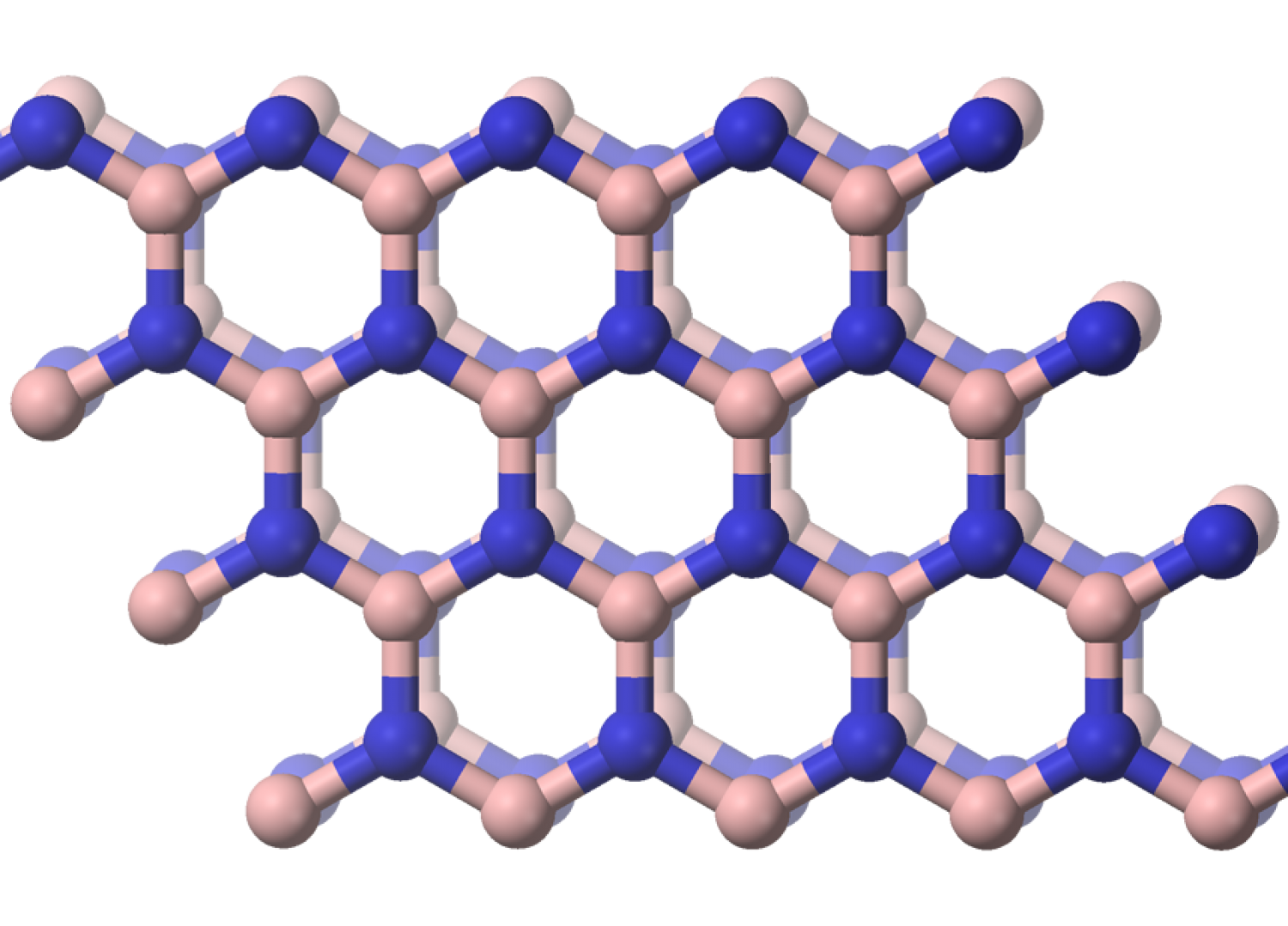

In recent years, new materials based on ceramics have developed rapidly. Boron nitride (BN) ceramics, a hexagonal crystal system with phosphorous flake structure and special physical and chemical properties, is a new industrial material developed with the development of aerospace and electronics industry and has a wide range of applications in industry and production. At present, the research on boron nitride mainly focuses on its hexagonal phase (h-BN) and cubic phase (c-BN). Hexagonal boron nitride has lubricity, thermal conductivity, and good high-temperature performance. Recent research shows that the hexagonal phase is also in thermodynamic equilibrium and stable state at room temperature and pressure. The main application field of hexagonal boron nitride is still as the raw material for synthesis of cubic boron nitride, while the cubic boron nitride is a kind of synthetic material, and has the application prospect in many fields.

Hexagonal boron nitride is known as white graphite, because it has a similar layered crystal structure and similar physical and chemical properties to graphite, such as good lubricity and thermal conductivity. Hexagonal boron nitride is commonly used as sintered ceramic materials. In addition, h-BN structural ceramics have been widely used in high-temperature insulation components, atomic energy, metallurgy, aviation, and other fields because of their high thermal conductivity, good electrical insulation performance, low thermal expansion coefficient, and the non-wettability of most metals. As a raw material for synthesis of cubic boron nitride, hexagonal boron nitride is a theoretical low-temperature stable phase, and its superior performance is more attractive, so hexagonal boron nitride is often used to synthesize cubic boron nitride.

Boron nitride ceramics have excellent thermal stability and dielectric properties. They are one of the few compounds that can be decomposed at a high temperature, and even have excellent thermal and electrical stability over a wide range of temperatures. However, due to the low strength, hardness, elasticity, high thermal conductivity, low corrosion resistance, and difficulty in forming shape components, single-phase boron nitride ceramics have not been really applied in the radon. As an advanced ceramic material, boron nitride has been widely favored in the field of material research for its superior mechanical properties. However, due to the harsh conditions of the present synthesis method, the application of boron nitride is affected to some extent. Therefore, the new synthesis method of boron nitride has become a hot topic in the research of boron nitride. The prereaction bodies were selected and the thermodynamic properties were used to reduce the external induced temperature and reaction temperature, as well as control the product morphology. By selecting the appropriate reaction process and controlling the reaction conditions, the product morphology and particle size can also be controlled.

Please visit https://www.preciseceramic.com/ for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments