What is the Piezoelectric Ceramic?

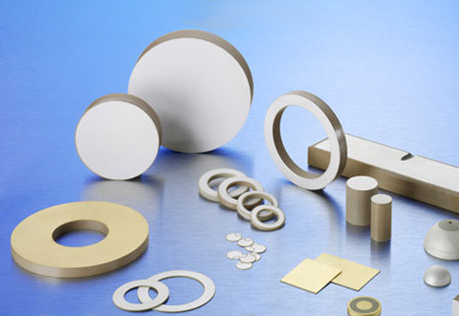

Piezoelectric ceramics, a subset of ferroelectric ceramics, exhibit notable piezoelectric effects, achieved through the polarization of polycrystalline materials composed of mixed oxides such as zirconia, lead oxide, and titanium oxide. These materials undergo high-temperature sintering and solid-state reactions to develop their robust mechanical and reliable piezoelectric properties. Widely utilized in sensors, ultrasonic transducers, and microdisplacement devices, piezoelectric ceramics serve as critical components in various high-tech fields, including electronics, aerospace, and information technology. Their unique ability to interact with mechanical, electrical, and thermal forces makes them indispensable in advancing material technology.

History of Piezoelectric Ceramic

In 1880, the Curie brothers first identified the piezoelectric effect in tourmaline, marking the inception of piezoelectric research. Subsequently, in 1894, Woldemar Voigt discovered piezoelectric properties in crystals of twenty asymmetric point groups, highlighting quartz as a notable example. During World War I, Paul Langevin, a successor to the Curie brothers, utilized quartz's piezoelectric properties to develop the first underwater ultrasonic detector for submarine detection. The exploration of piezoelectric materials expanded significantly after World War II with the discovery of Barium Titanate (BaTiO3). In 1947, Bernard Roberts enhanced the piezoelectric properties of BaTiO3 through high-pressure polarization treatments. This advancement spurred Japan to lead in developing BaTiO3-based devices, such as ultrasonic transducers and high-frequency sensors. Research continued into the 1950s, culminating in the development of single-crystal ferroelectric materials by the late 1980s, which significantly advanced three-dimensional ultrasonic imaging. Today, innovations include the integration of nanotechnology in manufacturing and the development of lead-free piezoelectric ceramics to enhance environmental sustainability.

The Curie Brothers

Characteristics of Piezoelectric Ceramic

Dielectric Properties:

Piezoelectric ceramics are characterized by their ability to respond to external electric fields, which are measured by their dielectric properties.

Elastic Properties:

The elasticity of piezoelectric ceramics is defined by their elastic coefficient, which measures the material's deformation in response to applied forces.

Piezoelectric Properties:

The most notable feature of piezoelectric ceramics is their piezoelectricity, encompassing both positive and inverse effects. Positive piezoelectricity involves the displacement of charge centers within the material under mechanical stress, leading to polarization and the creation of opposite charges on the material's surface.

Application of Piezoelectric Ceramic

Sound Transduction Applications:

Piezoelectric ceramics are extensively used as sound transducers in devices such as pickups, microphones, headphones, buzzers, and sonar systems. They can generate vibrations at various frequencies, controlled by electronic circuits, to emit diverse sounds. For instance, electronic music greeting cards use the inverse piezoelectric effect to convert AC audio signals into audible sound signals.

Piezo Detonators:

In military applications, piezoelectric ceramics are critical components in anti-tank weaponry. The ceramics convert the mechanical impact of a projectile hitting a tank into a high voltage, triggering an explosion that destroys the target.

Piezoelectric Ceramics for Anti-tank Weapons

Piezo Lighters:

Used predominantly in gas stoves, piezo lighters employ piezoelectric ceramics to generate a high voltage from a simple press of a button, producing a spark that ignites the gas. These lighters are praised for their ease of use, reliability, and longevity.

Piezoelectric ceramics for gas stoves

Nuclear Safety Goggles:

In the realm of safety, transparent piezoelectric ceramics are used in goggles designed to protect against the intense optical radiation from nuclear explosions. These goggles instantly convert radiation into high-voltage electricity, significantly dimming the light to safe levels within milliseconds, and then revert to their original state post-exposure. The goggles are lightweight and designed for easy integration with nuclear-proof safety gear.

Conclusion

We hope this article has enhanced your understanding of piezoelectric ceramics and their diverse applications. These materials play a pivotal role in advancing technology across multiple sectors, from consumer electronics to military and safety equipment. For further information or to explore more about piezoelectric ceramics and their uses, please visit Advanced Ceramic Materials (ACM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

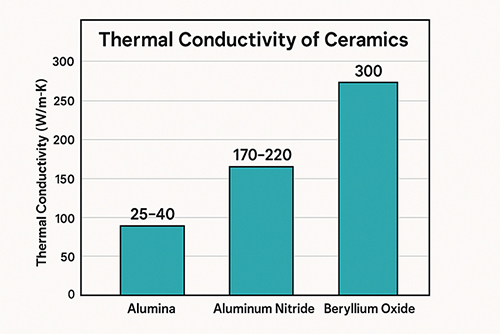

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity