Do you have any questions? Email Us

[email protected]

PBN Crucibles for Precision Application

Pyrolytic Boron Nitride Crucible can withstand high temperatures in a high vacuum environment. It has excellent thermal conductivity, corrosion resistance, and electrical resistance.

READ MORE >

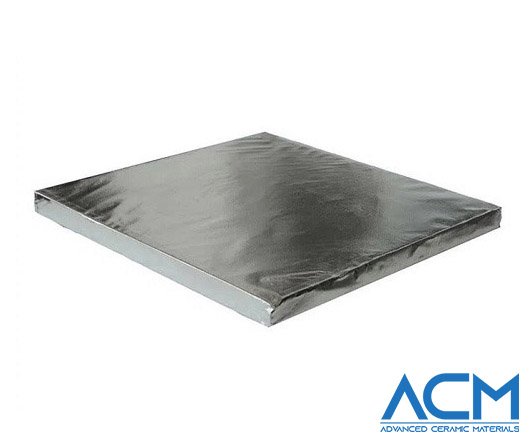

CF4412 Nano Microporous Insulation Board

Nano Microporous Insulation Board Description

Nano Microporous Insulation Board is crafted by combining high-purity Silicate and Ti2Si2O5 particle powder with binders. Utilizing unique microporous technology, this insulating material achieves superior thermal conductivity, surpassing that of still air at atmospheric pressure. Its insulation capabilities outperform traditional fiber insulation by a factor of 3-10.

Nano Microporous Insulation Board Specifications

|

Chemical Composition |

SiO2: 45% Ti2Si2O5 + SiO2: 50% |

SiO2: 50% Ti2Si2O5 + SiO2: 45% |

SiO2: 45% Ti2Si2O5 + SiO2: 45% |

|

Max. Working Temperature (℃) |

1200 |

1000 |

900 |

|

Density (g/cm3) |

220-350 |

220 |

220 |

|

Linder Shrinkage |

<2% |

||

Nano Microporous Insulation Board Applications

The application of Nano Microporous Insulation Board extends across various industrial kilns, including its use in heat insulation for the back lining of equipment in sectors such as petrochemicals, ceramics, glass kilns, mechanical engineering, non-ferrous industries, electricity, and heating furnaces for boiler equipment.

Nano Microporous Insulation Board Packaging

We handle our Nano Microporous Insulation Board with the utmost care during storage and transportation to maintain the product's original quality.

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 23661 Birtcher Dr. Lake Forest, CA 92630 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.