An Introduction to Cordierite Ceramic

Introduction

Silicate is a popular material for ceramic. It is one of the earliest technical ceramics with a variety of unique features including excellent electrical insulation, impressive tolerance to thermal shock, and low thermal conductivity.

Cordierite, mullite, steatite, and other silicate ceramic with desired features and various uses are available nowadays. Here, this article is going to focus on the production, properties, and applications of cordierite ceramic. Hope that you can have a better understanding of cordierite and silicates thereafter.

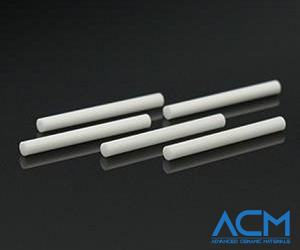

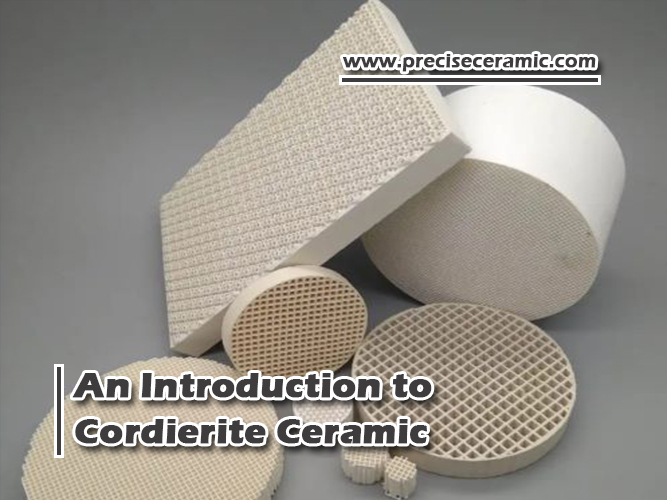

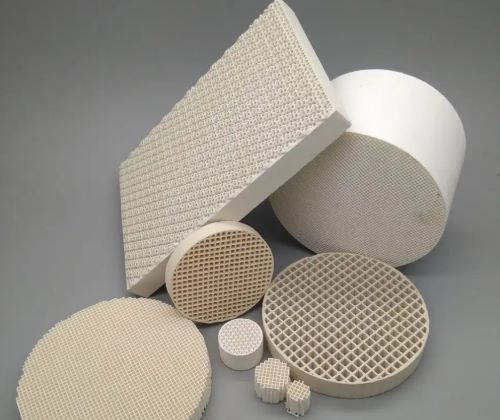

Figure 1. Cordierite Products

What Is Cordierite?

Cordierite (2MgO·2Al2O3·5SiO2) is a naturally occurring substance. It belongs to the silicate family and is composed of magnesium, aluminum, silicate, and iron elements. Cordierite ceramic was discovered in 1813 and got its name from the French geologist Louis Cordier. You can find this mineral in high-temperature metamorphic rocks, granites, and rhyolites. However, natural cordierite is not abundant. Therefore, various methods are developed to produce man-made cordierite at large scales.

How to Make Cordierite Ceramic?

The production of cordierite ceramic can be divided into three steps.

- The processing starts with powder preparation. Initially, reliable manufacturers mix talc, kaolin, and alumina powder rather than MgO, Al2O3, and SiO2 powder together because these compounds react more actively than pure oxide materials. You’d better select materials of finer particle size for a better reaction.

- In the second stage, a small amount of cordierite ceramic is synthesized at 1275 °C. A large amount of mullite and cristiballite is formed at the same time.

- At last, a bulk of high-quality cordierite is made as the temperature rises to 1335 °C. Remember to increase the operating temperature slowly since cordierite melts at 1460 °C.

What Are the Properties of Cordierite Ceramic?

Cordierite ceramic stands out for the following features.

Cordierite can be used at high temperatures up to 1200°C thanks to its excellent thermal shock resistance. It also possesses a low thermal expansion coefficient and a low thermal conductivity.

Additionally, cordierite has good insulation ability. It comes with a Mohs hardness of about 7, and it is resistant to creeps as well.

If you are interested in the mechanical and chemical properties of cordierite, check the table below for more information.

Table 1 The Features of Cordierite Ceramic

|

Density |

2.0-2.53g/cm3 |

|

Melting Point |

1460°C |

|

Thermal Expansion Coefficient from 25 to 1000°C |

1.4-2.6*10^-6/K |

|

Young’s Module |

139-150 GPa |

|

Flexural Strength At Room Temperature |

120-245 |

|

Relative Dielectric Constant |

5 K at 1 MHz |

[1]

What Is Cordierite Ceramic Used for?

Cordierite ceramic has numerous thermal engineering applications for both households and businesses.

- Kiln Furniture

Cordierite is widely used to make kiln furniture for its impressive thermal shock resistance. A cordierite kiln ware is 60% to 70% lighter than a traditional one. You can also get faster heat transfer with such ceramic kiln ware.

- Electric Equipment

Cordierite is commonly employed to produce insulation equipment and electric heating elements. For instance, you can find cordierite components used in fuses, thermostats, and lighting technology.

- Catalyst Carrier

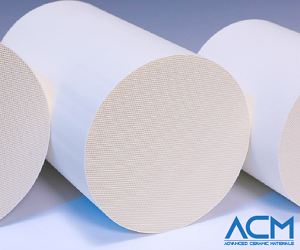

Cordierite heats up and cools down quickly, and no crack appears because of the temperature change. So, it is a choice material for catalyst carriers, which are mainly used for automobile exhaust purification and industrial exhaust deodorization.

Cordierite is perfect for the filtration of molten metal, and it usually takes the form of honeycombs or ceramic foam. For one thing, it could purify metal liquid and reduce impurities. For another, the product quality would be promoted and the casting cost would be reduced.

Conclusion

Cordierite is a technical ceramic with perfect thermal features, great dielectric ability, and high hardness. Therefore, cordierite ceramic is applied to manufacture thermal equipment, electric devices, catalyst carriers, and honeycomb filters. Advanced Ceramic Materials (ACM) is a leading supplier of advanced ceramics. Send us an inquiry if you are interested.

Reference:

[1] Chowdhury, Anirban & Maitra, Saikat & Das, Santanu & Sen, A. & Samanta, G.K. & Datta, Prithul. (2007). Synthesis, Properties, and Applications of Cordierite Ceramics, Part 1. InterCeram: International Ceramic Review. 56. 18-22.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

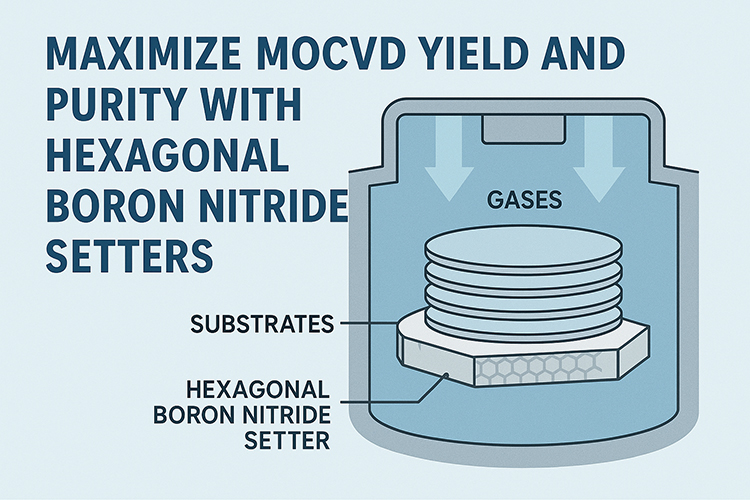

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity