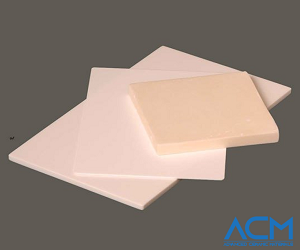

CC2291 Cordierite Plate, Silicate Plate

- Catalog No. CC2291

- Color Off-white

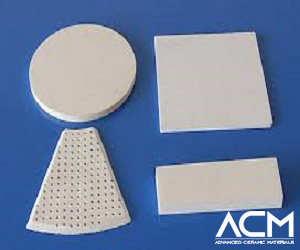

- Shape Plate

- Thermal Conductivity 3 W/m•K

- Compositions Mg2Al4Si5O18

- Classification Silicate

Datasheet

Inquiry

CC2291 Cordierite Plate, Silicate Plate

Cordierite Plate Description

Cordierite ceramic plate is made of silicate ceramic cordierite (Mg2Al4Si5O18). Cordierite is a commonly used structure ceramic material that has the advantage of energy efficiency and high-temperature resistance. Cordierite plate is widely used on a barbeque grill, burn ovens, convection ovens, gas ovens, rotary ovens, natural gas heaters, space heater crucibles, and various heating equipment, etc.

Advanced Ceramic Materials (ACM) is a trustworthy supplier of cordierite ceramic products.

Cordierite Ceramic Plate Characteristics

Cordierite plate has the following characteristics:

* Cordierite ceramic plate can withstand very high temperatures.

* Cordierite plates have a low thermal expansion, which is necessary when firing products quickly through a kiln.

* Excellent thermal shock properties

* Good mechanical strength

* Can be used up to approximately 1200°C

* Outstanding crack-resistance

Cordierite Plate Specifications

|

Properties |

Units |

Test |

Value |

|

Physical |

|||

|

Chemical Formula |

– |

– |

2MgO-2Al2O3-5SiO2 |

|

Density,?r |

g/cm3 |

ASTM C20 |

2.60 |

|

Color |

– |

– |

off-white |

|

Crystal Structure |

– |

– |

orthorhombic |

|

Water Absorption |

% @R.T. |

ASTM C373 |

0.02 – 3.2 |

|

Hardness |

Moh’s |

– |

7 |

|

Hardness |

knoop (kg/mm2) |

Knoop 100g |

— |

|

Mechanical |

|||

|

Compressive Strength |

MPa @ R.T. |

ASTM C773 |

350 |

|

Tensile Strength |

MPa @ R.T. |

ACMA Test #4 |

25.5 |

|

Modulus of Elasticity |

GPa |

ASTM C848 |

70 |

|

Flexural Strength?(MOR) |

MPa @ R.T. |

ASTM F417 |

117 |

|

Poisson’s Ratio,?u |

– |

ASTM C818 |

0.21 |

|

Fracture Toughness, KIc |

MPa x m1/2 |

Notched Beam Test |

— |

|

Thermal |

|||

|

Max. Use Temperature |

C |

No load cond. |

1371 |

|

Thermal Shock Resistance |

DT ( C) |

Quenching |

500 |

|

Thermal Conductivity |

W/m-K @ R.T. |

ASTM C408 |

3.0 |

|

Coefficient of Linear Thermal Expansion,?al |

mm/m- C (~25?C through ±1000?C) |

ASTM C372 |

1.7 |

|

Specific Heat, cp |

cal/g-?C @ R.T. |

ASTM C351 |

0.35 |

|

Electrical |

|||

|

Dielectric Constant |

1MHz @ R.T. |

ASTM D150 |

4.7 |

|

Dielectric Strength |

kV/mm |

ASTM D116 |

5.11 |

|

Electrical Resistivity |

Wcm @ R.T. |

ASTM D1829 |

1014 |

Cordierite Plate Application

Cordierite plates are widely used in various fields of electronics, electrical appliances, welding equipment, chemicals, machinery, railways, textiles, environmental protection, thermal engineering, instrumentation, mining machinery, post and telecommunications, and the defense industry.

Request a Quote

-

Attachment (Optional)

No file chosen