Benefits of PBN Coatings and Their Applications

Introduction

PBN (Pyrolytic Boron Nitride) coatings are becoming increasingly popular due to their unique thermal, chemical, and electrical properties, and numerous applications. These coatings are used in various industries such as electronics, aerospace, and semiconductor manufacturing. In this article, we will explore the benefits of PBN coatings and their applications. Hope that you can have a better understanding of PBN coating and select suitable PBN products for your projects.

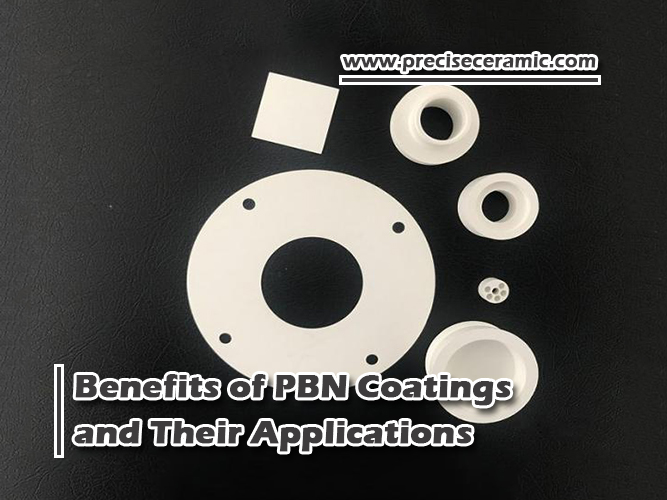

Figure 1. Pyrolytic Boron Nitride Ceramic

What Are PBN Coatings?

PBN coatings, or pyrolytic boron nitride coatings, are advanced ceramic materials with low density, high purity, good thermal conductivity, and dielectric strength. They are also called chemical-vapor-deposited boron nitride coatings since they are produced by chemical vapor deposition at high temperatures.

The coating is deposited on a substrate using a chemical vapor deposition (CVD) process. The chemical equation is BCl3+NH3 -> BN+3HCl. Such a process involves the decomposition of a gas mixture containing ammonia and boron halide at high temperatures and under high vacuum conditions, which results in the deposition of high-purity PBN coatings on the substrate.

Finally, quality PBN products are prepared in the form of sheets, tubes, rings, or thin containers, and the typical purity is 99.99%. All these PBN ceramics are available on our website.

Related reading: What is Pyrolytic Boron Nitride (PBN)?

Benefits of PBN Coatings

--High Thermal Conductivity

PBN coatings stand out for their impressive thermal performance, which makes them ideal for high-temperature applications. They can withstand temperatures up to 1800°C, making them suitable for use in semiconductor manufacturing and other high-temperature environments. Besides, their good thermal conductivity and toughness contribute to their excellent thermal shock resistance. So, PBN coatings could stand rapid heating and cooling.

--Chemical Inertness

Chemical inertness is another remarkable feature of PBN coatings. Namely, they are resistant to corrosion and oxidation. These coatings do not react with acid, alkali, salt, and organic reagents and remain inactive in most molten metals and semiconductors. Therefore, they are perfect for use in harsh chemical environments, such as the manufacturing of chemical processing equipment.

--Electrical Insulation

PBN coatings have excellent electrical insulation ability of 2x105 volts/MMC under direct current, and they are utilized to manufacture electronic devices including sensors, transistors, and other components. The dielectric strength of PBN coatings remains steady even at high temperatures.

--Low Coefficient of Friction

PBN coatings possess a low coefficient of friction, which means they reduce wear and tear in moving parts. They are commonly employed in the manufacturing of bearings, gears, and other moving components.

Applications of PBN Coatings

--PBN-coated Graphite Products

Pyrolytic boron nitride coatings are applied to make graphite tools in particular because the temperature of CVD is too high and the surrounding is highly corrosive. PBN-coated graphite materials come with better purity, lower porosity, and other promising features. For instance, they can stand high temperatures up to 2500°C. You can also find PBN coatings in liquid phase epitaxy.

Figure 2. PBN-coated Graphite Products

--Semiconductor Manufacturing

PBN coatings are widely used in semiconductor manufacturing as a container for single-crystal growth. They are insulation layers between different layers of electronic components because of their high thermal conductivity and insulation property. They serve as a protective coating for the wafer surface during the manufacturing process as well.

--Other Applications

- Aerospace Industry: You can employ PBN coatings to make thermal protection systems, rocket nozzles, and engine components. You can also find them in the production of satellites and space vehicles.

- Chemical Processing Industry: Thanks to their chemical inertness, PBN coatings are perfect for chemical processing equipment such as pumps, valves, and pipes.

- Medical Devices: They are popular for the manufacturing of implants, surgical instruments, and other medical devices due to their biocompatibility and chemical inactive properties.

Related reading: Introduction of Pyrolytic Boron Nitride (PBN)

Conclusion

PBN coatings offer a broad range of benefits, including high thermal conductivity, low coefficient of friction, chemical inertness, and electrical insulation properties. These properties make them desirable for semiconductor manufacturing, aerospace, chemical processing, and medical devices. With continued research and development, the potential applications of PBN coatings are limitless.

Advanced Ceramic Materials (ACM) is a trustable supplier of PBN ceramics of different sizes and configurations. Customized PBN coatings are also welcome. Send us an inquiry if you are interested.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments