Boron Nitride Insulators Used in PVD, CVD and Plasma Systems

Introduction

Boron nitride (BN) is a high-performance ceramic material that is widely used in a variety of industrial applications due to its unique properties, such as high thermal conductivity, high electrical resistance, and excellent chemical stability. One of the most popular applications of BN is as an insulator in PVD, CVD, and plasma systems. In this article, we will explore the benefits of using boron nitride insulators and how they are used in these systems. Hope that you can have a further comprehension of boron nitride insulators after reading this essay.

What Are PVD, CVD, and Plasma Systems?

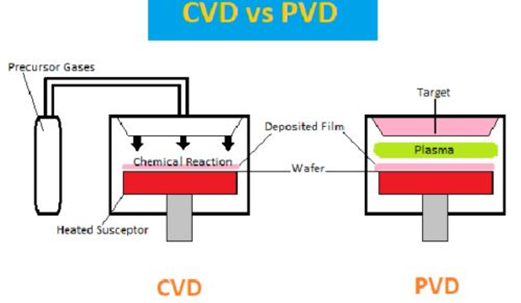

Physical vapor deposition (PVD), chemical vapor deposition (CVD), and plasma systems are all employed for the coating and surface treatment of materials.

PVD systems use a vacuum chamber to deposit thin layers of material onto a substrate with low work temperature. CVD systems deposit more uniform coating material with chemical reactions. PVD and CVD coatings also differ in the quality of coating and the operating temperatures. CVD could produce a uniform thin film even on uneven surfaces. PVD stands out for its relatively low temperature of about 450°C.

[1]

[1]

Figure 1. PVD VS CVD

CVD could be enhanced by plasma systems, known as plasma-enhanced chemical vapor deposition processes (PECVD). Compared with CVD, PECVD possesses very low deposition temperatures and can produce layers with better quality and less cracking. Boron nitride ceramics are important materials used to control the plasma bombardment in sputtering, thus preventing potential erosion and corrosion in the chamber.

In short, PVD uses physical changes, CVD chooses chemical reactions to obtain thin layers, and plasma systems employ plasma of gas ions to promote the coating.

Related reading: Table Comparison: Physical Vapor Deposition Vs. Chemical Vapor Deposition

Why Use Boron Nitride Insulators in the Film Coating Systems?

Boron nitride is an excellent insulator material for PVD, CVD, and plasma systems because of its desirable features as follows:

- Thermal Performance: BN exhibits remarkable heat resistance that it can stand high temperatures of above 1800°C in a vacuum or inert atmosphere as well. Additionally, BN has high thermal conductivity, which helps to reduce temperature gradients and ensures coating uniformity. Furthermore, BN’s excellent thermal shock resistance, enables it to withstand rapid temperature changes without cracking or breaking.

- Electrical properties: BN has a high electrical resistance of 1016-1018 Ω.cm at room temperature, so it can withstand high voltages and currents. This makes it ideal for use in plasma systems. BN is also characterized by high electrical breakdown strength, which is 3 to 4 times that of alumina ceramic.

- Chemical Inertness: BN is chemically stable and resistant to corrosion by most acids and alkalis, making it an ideal material for use in harsh environments. Pyrolytic Boron Nitride (PBN) is a type of boron nitride ceramic with extremely high purity and better physical and chemical properties. Therefore, PBN crucibles could stand in corrosive environments, especially in the semiconductor industry and electronic fields.

Related reading: Boron Nitride Overview: Properties, Production, and Uses

How Are Boron Nitride Insulators Used in These Systems?

Boron nitride insulators are utilized in PVD, CVD, and plasma systems in various ways. In PVD systems, BN insulators serve as substrate holders, keeping the substrate separate from the heating elements. In CVD systems, BN insulators are used to isolate the substrate from the reaction chamber and to provide a thermally stable environment. In plasma systems, they insulate the electrodes and could create a uniform plasma discharge. With boron nitride insulators, a thin but valid film can be formed with enhanced properties by PVD, CVD, or plasma systems.

Advanced Ceramic Materials (ACM) provides ideal insulation components made from boron nitride for your PVD, CVD, and plasma systems. You can get quality insulating rails, target frames, tubes, and liners for your deposition projects. Send us an inquiry if you are interested.

Conclusion

In a word, boron nitride insulators are essential components in PVD, CVD, and plasma systems, where they are used to provide high thermal conductivity, electrical resistance, chemical stability, and thermal shock resistance. By using BN insulators in these systems, it is possible to ensure that coatings and treatments are uniform, reliable, and of high quality. As such, boron nitride insulators are indispensable materials for modern surface coating and treatment technologies. There are many more useful boron nitride ceramic components on our website. Check our homepage for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments