Boron Nitride Nanotubes and Their Applications

Introduction

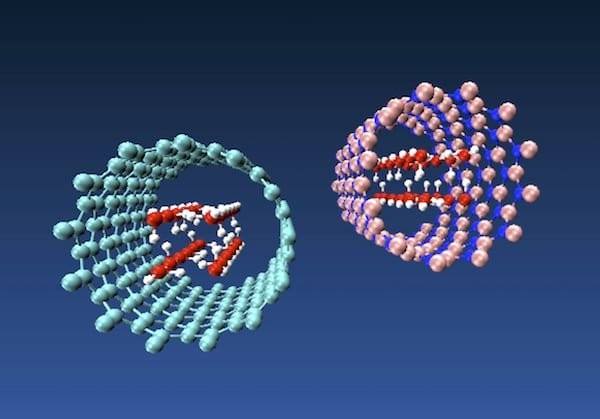

In the expansive field of nanotechnology, boron nitride nanotubes (BNNTs) have emerged as a subject of significant interest due to their unique properties and potential applications. First synthesized in 1995, these structures are similar in morphology to the better-known carbon nanotubes (CNTs) but are composed of boron and nitrogen atoms instead of carbon. This distinct composition endows BNNTs with exceptional mechanical strength, high thermal conductivity, and notable electrical insulation properties.

The diameter of these nanotubes is measured in nanometers, indicating their incredibly small scale and the precision required in their manipulation and use. Unlike carbon nanotubes, BNNTs exhibit transparency and are not affected by changes in chirality, making them versatile in various applications ranging from the optical industry to aerospace and biomedical fields. Their resilience at high temperatures and oxidation resistance also make them suitable for extreme environments. As we explore further, this article aims to delve into the synthesis, properties, and expanding applications of boron nitride nanotubes, highlighting their importance and future potential in modern technology.

Properties of Boron Nitride Nanotubes

Boron nitride nanotubes (BNNTs) share structural similarities with carbon nanotubes but are unique due to the chemical characteristics of boron and nitrogen. This composition provides BNNTs with several impressive properties that distinguish them from their carbon-based counterparts.

Thermal and Electrical Properties: BNNTs excel in thermal conductivity, allowing them to effectively manage heat in electronic and aerospace applications. This property, combined with their electrical insulation capabilities, makes BNNTs ideal for use in nanoelectronics where preventing electrical interference is crucial.

Mechanical Strength and Lightness: The tensile strength of BNNTs is comparable to that of carbon nanotubes, making them one of the strongest materials known, measured at the nanoscale. Their lightweight nature contributes to their applicability in creating strong yet lightweight composite materials for the aerospace and automotive industries.

Optical and Chemical Properties: One of the more striking properties of BNNTs is their optical transparency, which opens up uses in fields such as optoelectronics and protective coatings. Chemically, BNNTs are highly resistant to oxidation, even at high temperatures, surpassing many other nanomaterials' performance. This oxidation resistance also makes them suitable for high-temperature applications where other materials might fail.

Biocompatibility and Hydrophobicity: BNNTs are not only biomedically compatible, meaning they can be used within the body without adverse reactions, but they are also hydrophobic. This combination is particularly valuable in biomedical applications, where materials must resist moisture and not provoke immune responses.

Piezoelectric Properties: Unlike carbon nanotubes, BNNTs exhibit piezoelectric properties. They can generate an electric charge in response to mechanical stress, which is beneficial for sensors and energy-harvesting devices.

Further Reading: Differences in Properties Between Boron Nitride Nanotubes and Carbon Nanotubes

Synthesis of Boron Nitride Nanotubes

Boron nitride nanotubes are not quite easy to synthesize. A very high temperature is required for the synthesis of boron nitride nanotubes. In the past, there were many struggles associated with synthesizing boron nitride nanotubes. However, most of these challenges, which include the presence of impurities, have been overcome with advancements in technology. Some of the methods used to synthesize boron nitride nanotubes include.

Arc Discharge

This method of synthesizing boron nitride nanotubes was first used in 1995. It is the earliest method of boron nitride nanotube synthesis. At first, boron nitride rods were used in this method. However, with time, it was replaced by chemical compounds that contain boron. This replacement can be attributed to the fact that boron nitride rods are poor conductors. The major setback of this method is that boron nitride nanotubes cannot be produced in bulk.

Chemical Vapor Deposition

For a long time, Chemical Vapor Deposition (CVD) has been used to synthesize carbon nanotubes. However, it is also employed in the synthesis of boron nitride nanotubes. Both the boron nitride and the carbon nanotubes are synthesized similarly to the chemical vapor deposition method. In the presence of catalysts such as nickel and cobalt and a high temperature, solid and liquid sources of boron nitride are used to produce boron nanotubes in this method. A major advantage of this method is that there is greater control of the result. Unfortunately, like the arc discharge method, boron nitride tubes cannot be synthesized in bulk.

Ball Milling

This method is cheaper than the other methods previously mentioned. Also, with this method, boron nitride nanotubes can be produced in bulk. Iron is usually used as a catalyst in this method. The downside of this method is that the boron nitride nanotube produced has a significant amount of impurities.

Further Reading: Grinding & Milling: The Most Basic Machining Processes

Laser Ablation

The boron nitride nanotubes produced by this method are of top quality. Laser heat is used to melt a solid source of boron nitride in this method. Nickel and Cobalt are used as catalysts for this method.

Thermal Plasma Jet

The thermal plasma jet method involves using a plasma torch to vaporize boron in a nitrogen atmosphere. This method can produce BNNTs at a faster rate and higher quality compared to other methods. It is suitable for scaling up production due to its ability to operate continuously and handle larger quantities of material.

Applications of Boron Nitride Nanotubes

Boron nitride nanotubes (BNNTs) have found a wide range of applications across various industries due to their unique properties such as high thermal conductivity, mechanical strength, and chemical stability.

Aerospace

Boron nitride nanotubes are an asset in aerospace. The boron present in the nanotubes can be used with other materials to make them stronger and safer from harmful radiation. Boron nitride nanotubes can absorb harmful radiation because they can absorb neutrons effectively.

Nanocarriers

When Boron nitride nanotubes are allowed into the body, they have very little or no toxicity. Therefore, they can be used as nanocarriers. Nanocarriers are used in the pharmaceutical industry for drug delivery. They can be used to target specific organs and sites in the body, which would ordinarily be difficult to access due to their size.

Reinforcement

BNNTs are used to reinforce materials such as polymers, ceramics, and metals, enhancing their mechanical properties. For example, adding BNNTs to aluminum can significantly increase its strength and stiffness without adding substantial weight, which is particularly beneficial for automotive and aerospace applications.

Nanoelectronics

The high thermal conductivity and electrical insulation properties of BNNTs make them ideal for use in nanoelectronics, where they can help manage heat in densely packed electronic components. BNNTs are used in semiconductors, sensors, and other devices that require precise temperature control.

Energy

BNNTs have potential applications in energy systems due to their piezoelectric properties, which allow them to generate electricity from mechanical stress. This property can be utilized in energy harvesting devices, sensors, and actuators.

The Future of Boron Nitride Nanotubes

As we peer into the future of boron nitride nanotubes (BNNTs), it becomes evident that the trajectory of this remarkable material is set towards transformative advancements across various industries. With each passing year, research deepens our understanding of BNNTs, unlocking new potential applications and refining existing ones.

Advancements in Synthesis and Production

A key area of future development for BNNTs lies in the improvement of synthesis methods. Current production techniques, while effective, often face limitations regarding yield, quality, and scalability. Researchers are actively exploring more efficient routes for BNNT synthesis that promise higher yields and purer products at lower costs. Innovations such as plasma-enhanced chemical vapor deposition and high-temperature pressurized methods are on the horizon, potentially revolutionizing how BNNTs are produced and making them more accessible for industrial applications.

Emerging Applications

The unique properties of BNNTs such as high thermal conductivity, electrical insulation, and structural strength open up a myriad of applications that are only beginning to be explored. In the field of electronics, BNNTs could lead to the development of new types of insulating substrates and heat dissipators, critical for the next generation of high-power electronic devices. Additionally, the aerospace industry may benefit significantly from BNNTs due to their radiation shielding properties, offering enhanced protection for spacecraft and satellites.

Biomedical Innovations

In the medical realm, BNNTs hold potential as carriers for drug delivery systems due to their biocompatibility and structural features. Research is being conducted into how BNNTs can be used to target specific cells or organs, minimizing side effects and improving treatment efficacy for a variety of diseases, including cancer.

Neutron Shielding

One of the most promising applications of BNNTs is in neutron shielding. Their high neutron absorption capability makes them ideal candidates for creating safer environments in nuclear reactors and during space missions, where protection against cosmic radiation is crucial.

Enhancing Composite Materials

Finally, the mechanical reinforcement properties of BNNTs will continue to be leveraged to enhance the strength and durability of composite materials used in automotive, sports, and construction industries. The integration of BNNTs into polymers and other composites is set to deliver materials that are not only stronger and lighter but also more resistant to environmental factors such as heat and corrosion.

Conclusion

As research progresses, the future of BNNTs looks promising, with ongoing studies continually uncovering new properties and potentials. The continued development of synthesis technologies and the broadening of applications signify a bright future for BNNTs in transforming material science and technology. The integration of BNNTs into everyday materials and devices will likely be a hallmark of technological advancement in the coming decades. For those looking to explore or procure BNNTs, Advanced Ceramic Materials (ACM) offers a range of high-quality materials that cater to both research and industrial applications, positioning itself as a key player in the advancement of BNNT technologies.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

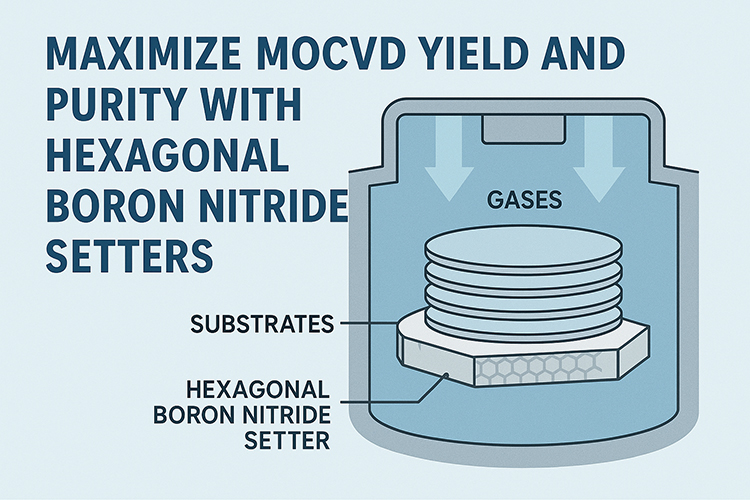

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity