Enhancing Boron Nitride with Surface Modification: Techniques and Their Impact

Introduction

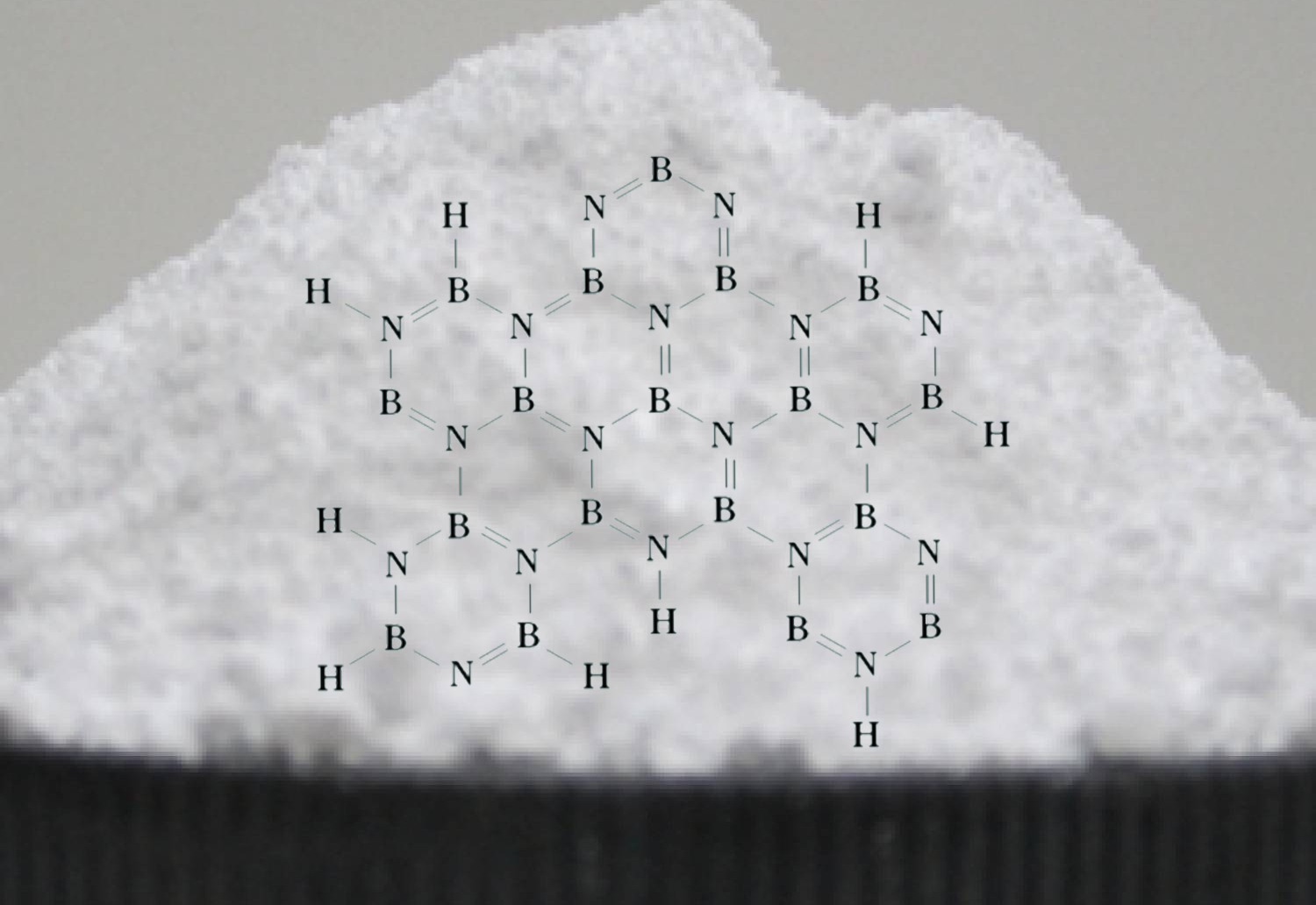

Boron nitride (BN) is valued for its high thermal conductivity, chemical inertness, and excellent lubricating properties. These characteristics make it a go-to material in areas like electronic packaging and advanced composites. Yet in practice, BN often struggles with weak interfacial bonding and poor dispersion—especially in composite matrices. These issues limit how well its intrinsic properties translate to real-world performance.

Surface modification offers a way forward. By adjusting the surface chemistry and structure, BN’s compatibility, processability, and overall function can be significantly improved.

What Makes Boron Nitride Unique

BN comes in different forms: from nano- and micron-sized powders to bulk materials like BN ceramics and thin films. Regardless of shape, it stands out for:

-

Strong thermal conductivity

-

Excellent electrical insulation

-

Chemical and thermal stability

-

Low friction surfaces

Its common applications include:

-

Thermal interface fillers in electronics

-

Solid lubricants for high-friction systems

-

Reinforcement agents in polymer or ceramic composites

How BN Surfaces Are Modified

1. Coating Techniques

Applying a surface coating helps BN blend better with other materials. Common choices include oxides like SiO₂ or Al₂O₃, polymers, and carbon layers.

Key methods:

-

Sol–gel processing for oxide coatings

-

CVD for uniform high-purity films

-

In situ polymerization to grow compatible shells directly on BN

These coatings improve dispersibility and create better bonds at material interfaces.

2. Elemental Doping

Doping BN with small amounts of carbon, oxygen, or fluorine adjusts its surface energy and sometimes its electronic characteristics.

This approach can:

-

Reduce interfacial thermal resistance

-

Improve thermal flow paths

-

Enhance lubrication behavior

Techniques include:

-

Solid-state reactions at high temperatures

-

Plasma-assisted doping

-

Chemical reduction or oxidation

3. Plasma Surface Activation

Plasma treatments are used to graft functional groups like –OH or –NH₂ onto BN particles. These groups make the BN surface more reactive or hydrophilic.

The benefits:

-

Better dispersion in liquids or resins

-

Stronger interaction with surrounding materials

-

Easier integration into composite matrices

4. Other Functionalization Approaches

-

Ultrasonication or mechanical milling helps deagglomerate particles and activate their surfaces.

-

Molecular grafting adds specific chemical handles for better interface bonding.

These techniques are often used in combination with coatings or doping for more robust results.

What These Modifications Actually Improve

1. Thermal Conductivity

The biggest bottleneck in composite heat transfer is usually the interface. Modified BN helps solve that by:

-

Reducing mismatch between filler and matrix

-

Eliminating surface defects that block heat flow

-

Creating continuous thermal pathways

2. Lubricating Performance

Doped or coated BN can reduce friction more effectively than raw BN.

-

Surface treatments form boundary layers that act as dry lubricants

-

Elemental doping changes surface energy, which alters slip behavior

This leads to smoother operation and less wear in moving parts.

3. Chemical and Thermal Stability

-

Surface coatings shield BN from oxidation or harsh chemical attack

-

Doped surfaces withstand higher temperatures without degradation

This matters most in corrosive or high-heat service environments like aerospace or energy systems.

4. Bonding and Compatibility

Functionalized BN shows:

-

Higher affinity for polymer or ceramic matrices

-

More uniform distribution throughout composites

-

Stronger load transfer at the microstructural level

The result is better mechanical performance without sacrificing thermal or electrical properties.

Use Cases in Industry

1. Modified BN in Composite Materials

Surface hydroxylation modification of BN powders (e.g., via ammonium persulfate-assisted hydrothermal methods) significantly enhances compatibility between BN and polymer matrices, effectively addressing the high interfacial thermal resistance typically seen in BN/polymer composites.

-

For instance, incorporating modified BN into polymers such as epoxy resin, polyvinyl alcohol (PVA), and polyimide results in composites with excellent thermal conductivity and electrical insulation.

-

These composites demonstrate thermal conductivity improvements exceeding 10 times that of pure polymers, reaching up to 7.9 W/(m·K), alongside enhanced elongation at break, indicating improved mechanical toughness and processability.

-

The typical preparation involves uniform dispersion of modified BN in polymer solutions, followed by curing and molding—an environmentally friendly and scalable industrial process.

2. Modified BN in Electronic Packaging

Modified BN powders are widely used in thermal management substrates for electronic packaging due to their high thermal conductivity and improved interfacial bonding.

-

Surface doping and plasma treatments increase BN surface activity, promoting stronger adhesion with encapsulant materials, thereby reducing interfacial thermal resistance and boosting heat dissipation efficiency.

-

Enhanced thermal management prolongs device lifespan and stabilizes performance, meeting the demands of high-power and high-density electronic components.

3. BN in 3D-Printed Thermally Conductive Composites

3D printing technology enables the controlled alignment of BN fillers within thermoplastic polyurethane (TPU) matrices, substantially improving composite thermal conductivity.

-

For example, hexagonal boron nitride (h-BN) combined with TPU via 3D printing allows directional alignment of BN fillers, minimizing thermal resistance pathways.

-

This approach not only enhances heat conduction but also improves mechanical properties, expanding BN’s application in complex, customized electronic heat dissipation devices.

4. Other Applications

-

In lubricants, modified BN leverages its excellent lubrication and chemical stability to reduce friction and wear, extending equipment service life.

-

In high-temperature corrosion-resistant materials, coating and doping modifications enhance durability and oxidation resistance, suitable for protective coatings and functional materials in extreme environments.

Conclusion

BN surface modification is not a one-size-fits-all solution—it’s a toolbox. Depending on your application, different combinations of coatings, dopants, and functional groups can be used to optimize performance.

The right modification approach allows BN to deliver not just its intrinsic thermal and chemical stability, but also better processability, integration, and durability in complex systems.

At Advanced Ceramic Materials (ACM), we supply both raw and surface-modified boron nitride tailored for industrial use. Contact us to discuss how BN can enhance your next project.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments