Ceramic Material Selection Made Easy: A Buyer's Guide to Key Properties

1. Introduction

Ceramic materials are essential in many industries. They’re found in electronics, machinery, construction, and even household products. However, selecting the right ceramic can be challenging. Each type of ceramic has unique properties that make it ideal for certain uses. Some handle high temperatures; others are resistant to wear or corrosion. Knowing these properties helps buyers choose the right material for their needs. This guide breaks down the main ceramic types and their key properties to make selection easy and effective.

2. Types of Ceramic Materials

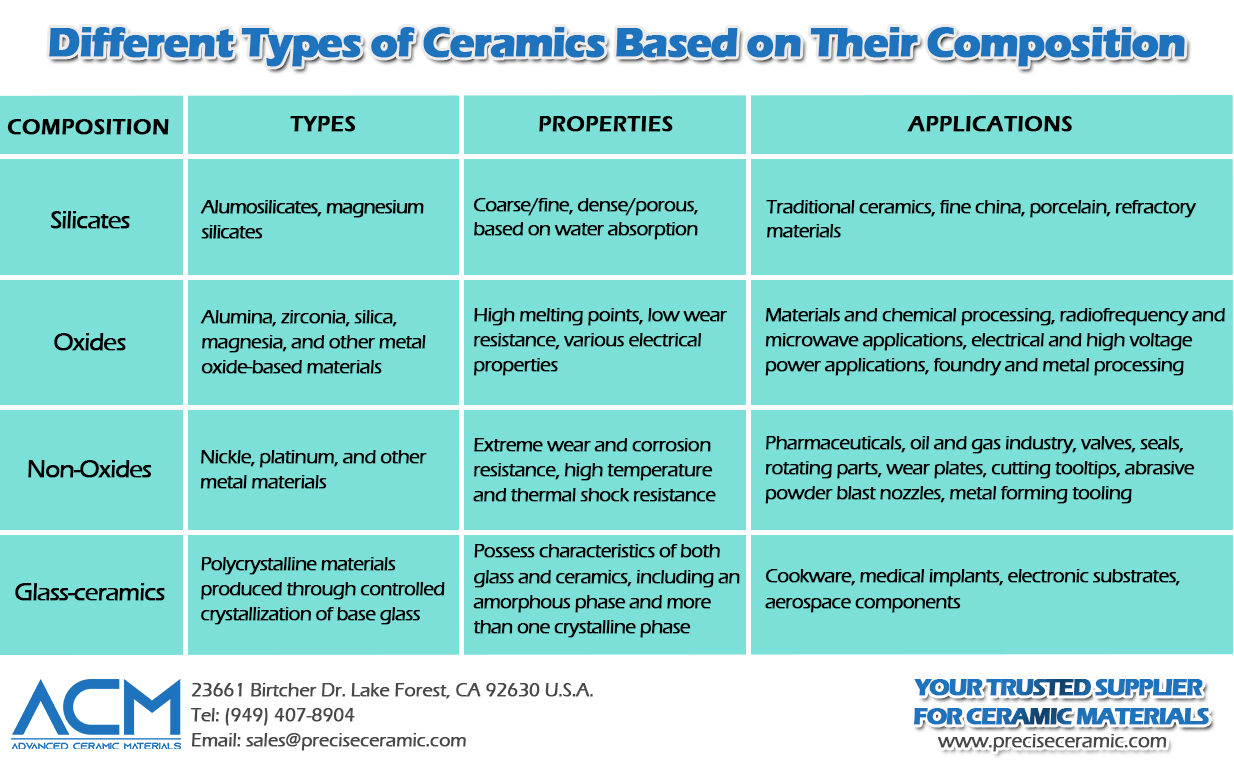

Different types of ceramics suit different applications. Here are the main types to know:

-

Silicate Ceramics: Silicate ceramics include traditional ceramics like clay, porcelain, and stoneware. They’re often used in construction, household items, and decorative products. Silicates are durable, cost-effective, and can be shaped easily, but they are not as heat-resistant as other ceramics.

-

Oxide Ceramics: Oxide ceramics, such as alumina and zirconia, are very stable and resistant to high temperatures and corrosion. They’re commonly used in industrial applications that need materials to withstand harsh environments. Oxides are often found in electronics, medical implants, and high-temperature machinery.

-

Non-Oxide Ceramics: Non-oxide ceramics include carbides (like silicon carbide) and nitrides (like silicon nitride). These materials are exceptionally strong and wear-resistant. They’re also good conductors of heat. Non-oxides are common in cutting tools, engine components, and any application where high strength and durability are required.

-

Glass Ceramics: Glass ceramics are a hybrid between glass and crystalline ceramics. They are impact-resistant and can handle moderate heat. Glass ceramics are often used in kitchenware, stovetops, and decorative items due to their strength and aesthetic appeal.

3. Key Performance Parameters Explained

3.1 Thermal Conductivity

Thermal conductivity shows how effectively a ceramic material transfers heat. For applications like electronics, where rapid heat dissipation is crucial, silicon carbide (SiC) is highly favored. It has a thermal conductivity of approximately 120–250 W/m·K, which is significantly higher than many other ceramics. This makes it ideal for electronic substrates and heat sinks, where fast heat transfer protects components from overheating. Silicon carbide’s high thermal conductivity ensures stable performance in systems that operate continuously at high temperatures.

Read more: Top 10 Ceramic Materials with the Highest Thermal Conductivity

3.2 Thermal Stability

Thermal stability refers to a ceramic material’s ability to endure extreme temperatures without breaking down or losing strength. This property is essential in high-heat environments, such as industrial kilns, engines, or any application facing prolonged thermal exposure. Alumina (Al₂O₃) is an excellent example due to its impressive stability at temperatures up to 1700°C. This makes alumina ideal for applications like furnace linings and kiln shelves, where consistent performance under intense heat is crucial. Alumina’s high melting point and resistance to thermal degradation ensure it remains reliable and intact, even in the harshest high-temperature conditions.

3.3 Wear Resistance

Wear resistance measures how well a ceramic endures abrasion or friction over time. Silicon nitride (Si₃N₄) stands out for its exceptional wear resistance, with a hardness rating of around 1500 Vickers and a fracture toughness of 7–10 MPa·m¹/². These qualities make silicon nitride a top choice for applications like cutting tools, bearings, and high-performance parts in heavy machinery. The high hardness and durability allow it to handle constant friction without significant wear, maintaining performance over extended use.

3.4 Corrosion Resistance

Corrosion resistance determines a ceramic’s durability in chemically reactive environments. Zirconia (ZrO₂) is a prime example, showing remarkable resistance to chemical attack and oxidation. It performs well in corrosive settings, such as chemical processing or medical devices, withstanding exposure to various acids and alkalis without degrading. Zirconia is used in tubing and implants, and its ability to resist corrosion ensures stability and safety in applications where chemical exposure is a regular challenge.

3.5 Resistivity

Resistivity measures a ceramic’s capacity to resist electrical currents, which is essential for insulation. Aluminum nitride (AlN) has a high resistivity of around 10¹² Ω·cm, making it a great insulator for electronic applications. It also combines high thermal conductivity (170–180 W/m·K), which is unique for insulating materials. Aluminum nitride is widely used as an insulating substrate in electronics, where its ability to prevent electrical flow while dissipating heat is highly beneficial for circuit stability.

3.6 Other Considerations

- Density: Materials like silicon carbide have a high density of 3.1–3.2 g/cm³, which adds stability in load-bearing applications.

- Impact Resistance: Glass ceramics, such as lithium aluminosilicate, have a high impact resistance due to their unique structure. They can withstand significant thermal shock, with typical coefficients of thermal expansion as low as 0.05–0.10 × 10⁻⁶ /°C, making them suitable for cookware and kitchen surfaces that experience sudden temperature changes.

4. Recommended Properties by Application

4.1 High-Temperature Applications

High-temperature environments, such as industrial furnaces, kilns, and engine components, require materials with outstanding thermal stability. Alumina (Al₂O₃) and Zirconia (ZrO₂) are ideal choices due to their ability to withstand extreme heat without degrading. Alumina, for example, remains stable at temperatures up to 1700°C and offers excellent thermal shock resistance, meaning it resists cracking from sudden temperature changes. This makes it suitable for furnace linings, kiln shelves, and other applications exposed to fluctuating high temperatures. Zirconia, with its enhanced toughness and stability up to 2400°C in certain forms, is commonly used in parts exposed to cyclic heating and cooling, such as jet engine components. Choosing ceramics with high thermal stability in these scenarios reduces the risk of failure and enhances equipment lifespan.

4.2 Electronics and Insulation

For electronic substrates, circuits, and insulation parts, ceramics with high resistivity and moderate thermal conductivity are essential. Aluminum Nitride (AlN) is highly valued for its unique combination of high electrical resistivity (~10¹² Ω·cm) and thermal conductivity (up to 180 W/m·K). These properties allow it to act as an excellent insulator while also helping dissipate heat, a key feature in electronic devices where heat buildup can damage components. Aluminum nitride is widely used in power electronics, LED packaging, and other heat-sensitive areas where both electrical isolation and thermal management are critical. Its balance of properties minimizes overheating and improves the performance of electronic assemblies, making it a reliable choice in advanced electronics.

4.3 Machinery and Tools

Ceramics used in high-wear environments, such as bearings, cutting tools, and other machinery components, need to exhibit superior wear resistance and hardness. Silicon Nitride (Si₃N₄) is one of the best options due to its combination of hardness (about 1500 Vickers) and high fracture toughness (up to 10 MPa·m¹/²). These properties make silicon nitride resistant to wear, cracking, and mechanical stress. Silicon nitride is commonly used in applications that experience high loads and constant friction, such as metal-cutting tools, ball bearings, and engine parts in automotive and aerospace industries. Its high wear resistance ensures long-lasting performance, reducing maintenance costs and downtime in machinery.

4.4 Chemical and Medical Environments

In environments exposed to chemicals, moisture, or bodily fluids, ceramics must exhibit high corrosion resistance to remain effective. Zirconia (ZrO₂) excels in these settings, showing strong resistance to acidic and alkaline environments as well as to oxidation. Zirconia’s stability allows it to maintain integrity when used in chemically active areas, such as chemical processing equipment and laboratory setups. Additionally, zirconia is biocompatible, making it suitable for medical implants like hip joints and dental crowns. Its durability in the face of chemicals ensures a long product life, which is especially important in environments where material degradation could lead to costly replacements or health risks.

4.5 Household and Decorative Use

For household items like cookware, kitchen surfaces, and decorative pieces, impact resistance and moderate heat resistance are key. Glass-ceramics, particularly lithium aluminosilicate, are popular in this category. These ceramics are engineered for thermal shock resistance, with very low coefficients of thermal expansion (approximately 0.05–0.10 × 10⁻⁶ /°C), meaning they can withstand sudden temperature changes without cracking. This makes them perfect for stovetops, oven doors, and cookware that frequently experience temperature shifts. In addition to functionality, glass ceramics also provide aesthetic appeal, with options in various colors and finishes, enhancing both the look and durability of household items.

5. Selecting the Right Ceramic Material

Choosing the best ceramic material involves evaluating its properties against your specific needs. Follow these steps to make an informed decision:

5.1 Define the Application

Start by identifying where and how the ceramic will be used. Consider factors such as operating temperatures, exposure to chemicals, required durability, and potential electrical insulation needs. For example, if the application is in an industrial furnace, high thermal stability is critical. For electronic substrates, you’ll need materials with good electrical insulation and thermal conductivity. A clear understanding of the application helps narrow down essential properties.

5.2 Prioritize Key Properties

After defining the application, prioritize the performance properties that matter most. For heat-intensive uses, thermal stability should be at the top of the list. For moving mechanical parts, wear resistance and hardness will be crucial. Create a checklist with ranked properties to focus on, based on the unique demands of your application. This prioritization ensures that you only consider materials that can handle the specific stresses and conditions of the intended environment.

5.3 Compare Material Options

With prioritized properties in mind, compare different ceramic types and assess their strengths. Use a chart or table to match each material (such as alumina, zirconia, silicon nitride) with your desired properties. Evaluate the exact performance data, like maximum operating temperature, hardness, or corrosion resistance levels. This step helps you see clearly how each ceramic measures up to your requirements and simplifies the selection process.

5.4 Review Product Specifications and Standards

Check if the ceramic materials meet industry standards or certifications, especially for critical applications like medical or aerospace. Verify technical datasheets and manufacturer specifications to ensure that the chosen ceramic material meets all regulatory and safety standards. This is especially important for applications where product failure could lead to significant costs or safety hazards.

5.5 Consider Cost and Availability

Balance the material’s performance with its cost and availability. Some ceramics, like zirconia, may offer excellent properties but come with a higher price tag. If the application allows, you may find more affordable options, such as alumina, which provides good performance at a lower cost. Availability is also crucial for projects requiring large quantities or specific dimensions, so check with suppliers on stock levels and lead times.

Taking these steps allows you to choose a ceramic material that meets both technical and practical requirements. By focusing on application needs, prioritizing key properties, and balancing performance with cost, you can select the ceramic that will offer the best results for your specific purpose.

6. Conclusion

Selecting the right ceramic material requires a clear understanding of essential properties and how they align with specific applications. Whether for high-temperature industrial environments, precision electronics, or household use, ceramics offer unique advantages in durability, stability, and resistance to wear, heat, and chemicals. Advanced Ceramic Materials (ACM) enhance these benefits, providing even greater performance in specialized applications that demand high reliability.

By prioritizing key properties like thermal stability, wear resistance, corrosion resistance, and electrical insulation, and balancing these with practical factors like cost and availability, you can make an informed choice. This guide offers a foundational approach to navigating the range of ceramic materials, ensuring the best fit for your project’s requirements and long-term performance needs.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments