Alumina vs. Beryllia: Comprehensive Comparison of Thermal Conductivity, Electrical Resistivity, and Cost

Introduction

Alumina (Aluminum Oxide, Al₂O₃) and Beryllia (Beryllium Oxide, BeO) are two valuable materials in modern industries. Both have strong properties that make them popular in electronics, aerospace, and advanced manufacturing. Alumina is known for its versatility and is widely used across many fields, while Beryllia stands out for its unique high-performance traits.

This article compares alumina and beryllia based on three critical factors: thermal conductivity, electrical resistivity, and cost. By examining these features, we can see how each material meets specific industry needs and understand which is best for different applications. Whether choosing a material for heat dissipation or insulation, this comparison offers a clear guide to help make the right choice.

Thermal Conductivity Comparison

Thermal conductivity measures how well a material conducts heat. It’s essential when choosing materials for devices that need to stay cool, like high-power electronics or equipment with tight heat control.

Alumina has moderate thermal conductivity. It transfers heat, but not as efficiently as some other materials. This makes alumina suitable for general electronic applications where heat dissipation is important but not the main focus. Many industries use alumina in devices that don’t face extreme temperatures, as it provides reliable performance at a reasonable cost.

Beryllia, however, has exceptionally high thermal conductivity. It can conduct heat faster and more effectively than alumina. This quality makes beryllia ideal for applications that require efficient heat transfer, such as high-performance electronics or aerospace components. Beryllia's ability to keep equipment cool extends the life of sensitive parts, ensuring stable and long-term function in demanding settings.

Electrical Resistivity Comparison

Electrical resistivity shows how well a material resists the flow of electric current. High resistivity is essential in materials used for electrical insulation, as it prevents unwanted current flow that could damage components.

Alumina has a high resistivity, making it a strong insulator in many electronics. It maintains this property across a broad temperature range, which makes it suitable for general-purpose insulation. Many industries, especially electronics, use alumina because it combines good insulation with affordability.

Beryllia also offers high resistivity, but it has additional benefits due to its unique dielectric properties. This makes beryllia especially useful in specialized applications where both insulation and specific electric characteristics are required. Beryllia’s strong insulating power combined with its excellent thermal conductivity gives it an edge in high-frequency and high-power devices, such as RF systems.

Cost and Market Demand

The cost of a material often affects its popularity and application. Alumina is widely available and generally affordable. Its lower cost and versatility make it suitable for a variety of industries, from electronics to construction. This affordability has contributed to alumina’s high demand, as it offers reliable performance for many common applications without straining budgets.

Beryllia, on the other hand, is more expensive. Beryllium, the base element of beryllia, is less common and requires careful handling due to health risks. These factors make beryllia costly to produce. However, the higher price is often justified in specialized fields where its unique properties—like high thermal conductivity and strong insulation—offer distinct advantages. As a result, beryllia is in demand mainly in high-end applications, such as aerospace and advanced electronics, where performance outweighs cost concerns.

To summarize the differences in thermal conductivity, electrical resistivity, and cost, the table below provides a quick comparison of alumina and beryllia’s key properties.

| Property | Alumina (Al₂O₃) | Beryllia (BeO) |

| Thermal Conductivity | ~30 W/m·K | ~200–330 W/m·K |

| Electrical Resistivity | ~10¹² Ω·cm | ~10¹⁰ Ω·cm |

| Cost | Low; commonly used | High; used in specialized fields |

Applications and Industry Usage

Alumina and beryllia each serve unique roles across industries due to their distinct properties.

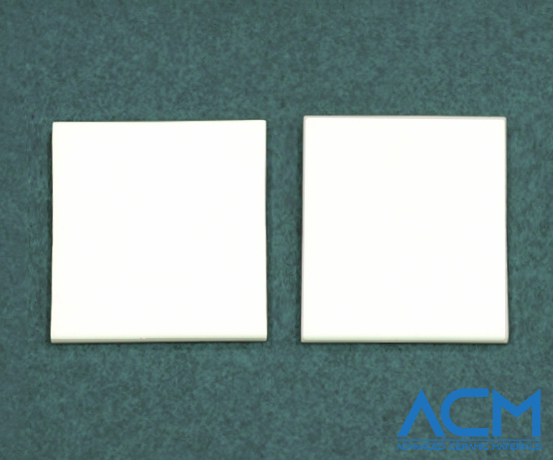

Alumina is widely used in electronics, automotive parts, and household products. Its affordability and reliable insulation make it a popular choice for applications that don’t demand extreme heat transfer. For example, alumina is commonly used in circuit boards and insulators where electrical insulation is needed. Its durability also allows it to perform well in wear-resistant parts and components that face moderate temperatures.

Further Reading: Where is Alumina Used?

Beryllia, on the other hand, shines in specialized, high-performance fields. Its excellent thermal conductivity and strong electrical insulation make it ideal for aerospace components, advanced electronics, and RF systems. For instance, beryllia is often used in satellite systems, high-frequency communication devices, and medical equipment where efficient heat dissipation is essential. Despite its higher cost, industries invest in beryllia when performance and reliability are critical, as it extends the life of sensitive equipment under demanding conditions.

Conclusion

In comparing alumina and beryllia, it’s clear that each material has unique strengths suited to different needs. Alumina is affordable and versatile, making it a practical choice for many industries. Its moderate thermal conductivity and strong electrical insulation make it reliable for general-purpose electronics and automotive applications.

Beryllia offers superior performance where heat dissipation and insulation are critical. Although it comes with a higher cost, it’s the preferred option for high-end applications, like aerospace and advanced electronics, that demand top-tier thermal and electrical properties.

Advanced Ceramic Materials (ACM) offers both alumina and beryllia products for a wide range of applications. If you’re unsure which material best suits your project, feel free to contact us—our engineers are ready to provide guidance tailored to your specific needs.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

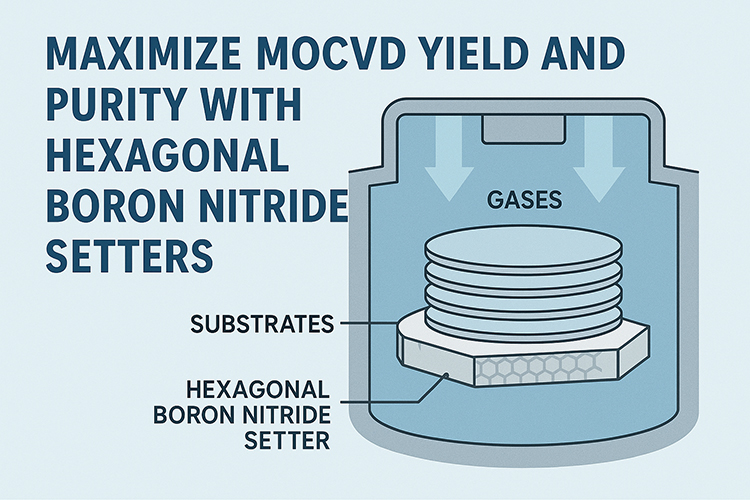

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity