Comprehensive Guide to Cutting Techniques for Ceramic Materials

I. Introduction

Ceramic materials are celebrated for their exceptional hardness, thermal stability, and resistance to wear, making them integral to various high-stakes applications across industries—from aerospace to biomedical devices. However, the very properties that make ceramics so valuable also make them challenging to machine and shape. Cutting techniques for ceramic materials, therefore, must not only be highly effective but also meticulously chosen to maintain the integrity of the ceramics while achieving the desired dimensions and finishes.

The evolution of cutting technologies has been driven by a continuous push towards enhancing precision and reducing waste, and today, manufacturers have a broad array of methods to choose from. This article delves into the most prevalent cutting methods employed in the ceramics industry, highlighting the tools and technologies that have revolutionized this field. From traditional abrasive methods to advanced non-abrasive techniques such as laser cutting and ultrasonic machining, we will explore how these technologies cater to the diverse needs of ceramic machining, enabling the creation of components with unprecedented precision and efficiency.

QUICK GUIDE:

- I. Introduction

- II. Overview of Ceramic Cutting Tools

- III. Ceramic Cutting Techniques

- IV. Factors Influencing Cutting Method Selection

- V. Case Studies and Applications

- VI. Conclusion

Figure1. Silicon Nitride Tools

II. Overview of Ceramic Cutting Tools

When it comes to machining ceramics, the choice of cutting tools is paramount due to the inherent hardness and brittleness of ceramic materials. The most commonly used ceramic cutting tools fall into several categories, each suited for different machining needs and ceramic types.

Diamond Tools

Diamond, the hardest material known, is often used in tools for machining ceramics due to its ability to cut through almost any material with precision. Diamond tools are especially effective for detailed and fine machining, producing high-quality surface finishes. These tools are typically used in grinding, milling, and cutting processes that require a high level of precision.

Carbide Cutters

Tungsten carbide is another popular choice for cutting ceramic materials, prized for its stiffness and resistance to wear. Carbide cutters are more robust than diamond tools and are used for roughing operations where substantial material removal is necessary. They are not as hard as diamond but offer a good balance between cost, durability, and performance.

Silicon Nitride Tools

Known for their thermal stability and resistance to thermal shock, silicon nitride tools are used extensively for high-speed machining applications. These tools can withstand higher temperatures than carbide and are ideal for operations where heat build-up is a concern, such as high-speed milling and turning.

Further Reading: Silicon Nitride Ceramic Cutting Tools Used in Machining Superhard Materials

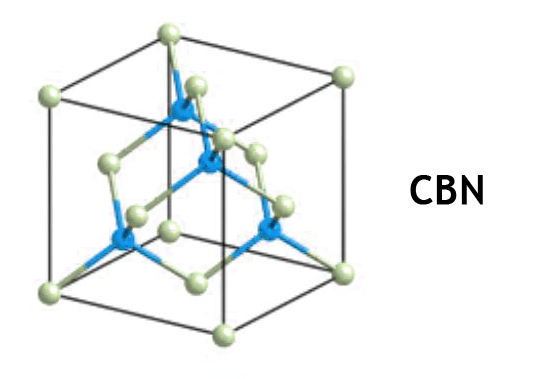

Cubic Boron Nitride (CBN) Tools

CBN is second only to diamond in hardness and is used for machining very hard ceramic materials. CBN tools are excellent for cutting tough ceramics and are commonly used in grinding operations where precision and surface integrity are crucial.

The selection of the right cutting tool depends on several factors, including the type of ceramic material, the complexity of the component, and the desired finish. Each tool type brings specific advantages to the machining process, and often, a combination of these tools is used to achieve the best results. Understanding the properties and benefits of each tool type is essential for optimizing the machining process and ensuring the durability and effectiveness of the ceramic components produced.

Table 1: Comparison of Ceramic Cutting Tools

III. Ceramic Cutting Techniques

Ceramic cutting techniques can be broadly categorized into abrasive and non-abrasive methods, each with specific applications that leverage their unique advantages for machining hard ceramic materials.

Abrasive Cutting Methods

1. Grinding: Grinding is the most common abrasive method used for ceramics and involves the use of high-speed rotating wheels composed of diamond or cubic boron nitride (CBN). This method is particularly effective for achieving precise surface finishes and intricate tolerances. Grinding can be further subdivided into surface grinding, cylindrical grinding, and creep feed grinding, each suitable for different types of ceramic shapes and size requirements.

CBN Grinding Wheel

2. Lapping and Polishing: These are finer abrasive processes where loose abrasives are used to produce highly polished surfaces. Lapping involves an abrasive slurry that runs between the workpiece and a rotating or oscillating tool, slowly wearing away the ceramic surface to achieve flatness and a mirror-like finish. Polishing, often a continuation of lapping, uses finer abrasives to achieve optical-quality finishes.

3. Honing: This method uses abrasives on a tool to create a controlled surface condition on the ceramic. It is commonly used to improve the geometry of a part, surface texture, and provide a tight dimensional tolerance. Honing is essential for applications requiring smooth surface finishes inside bores or tubes.

Non-Abrasive Cutting Methods

-

Laser Cutting: Utilizing the concentrated power of a laser beam directed at the ceramic material, laser cutting allows for precise cutting of extremely hard ceramics without physical contact. This method is ideal for producing intricate designs and shapes with high precision and minimal material waste.

-

Ultrasonic Machining: This technique involves the use of a tool that vibrates at ultrasonic frequencies to drive an abrasive slurry against the workpiece. The rapid impacts of the abrasive particles chip away the ceramic material at a controlled rate. Ultrasonic machining is particularly useful for drilling, milling, and engraving operations on brittle ceramic materials.

-

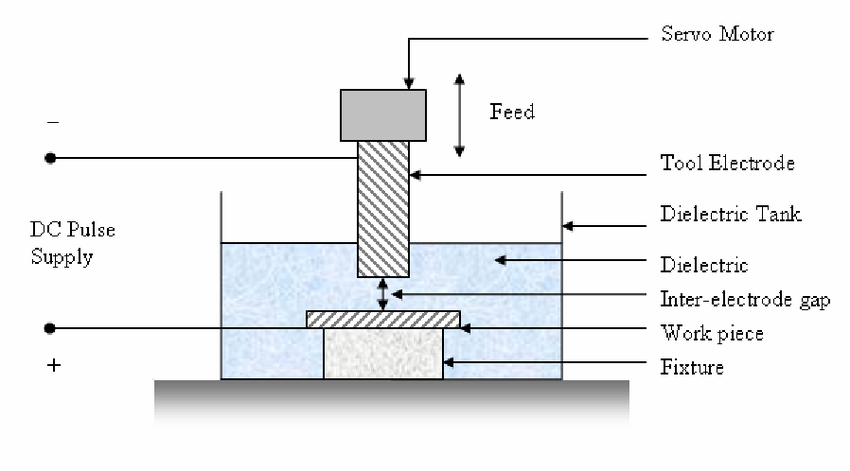

Electrical Discharge Machining (EDM): Although less common for ceramics due to their insulating properties, EDM can be employed for certain types of conductive ceramics. This process uses electrical discharges (sparks) that erode the material in a very controlled fashion. It is particularly useful for intricate or hard-to-machine components that are difficult to tackle with other methods.

Saha, Sourabh. (2008). Experimental Investigation of the Dry Electric Discharge Machining (Dry EDM) Process.

Each of these cutting techniques has specific benefits and is chosen based on the requirements of the project. For example, grinding is preferred for its ability to handle hard materials and achieve precise dimensional tolerances, while laser cutting is favored for complex shapes and fine details without inducing stress in the ceramic. Ultrasonic machining provides a unique solution for materials that are too brittle for traditional cutting methods.

Table 2: Ceramic Cutting Techniques and Their Applications

By selecting the appropriate cutting technique, manufacturers can optimize the machining process to enhance production efficiency, reduce costs, and achieve the desired qualities in the finished ceramic components. The decision often involves considering factors such as the hardness of the ceramic, the complexity of the part, the production volume, and the required precision of the final product.

IV. Factors Influencing Cutting Method Selection

Choosing the optimal cutting method for ceramic materials involves several critical considerations, each influenced by the specific characteristics of the ceramic type and the requirements of the machining task. Understanding these factors can significantly impact the efficiency, cost-effectiveness, and quality of the final product.

1. Material Hardness and Brittleness

The inherent hardness and brittleness of ceramic materials are perhaps the most crucial factors to consider. Harder ceramics like silicon carbide and boron carbide require more robust cutting tools like diamond or CBN, which can handle their abrasive nature without excessive wear. Conversely, softer ceramics might be machined effectively with less costly tools.

2. Complexity of Component Design

The geometric complexity of the component also dictates the cutting method. Intricate designs with tight tolerances often necessitate precision methods such as laser cutting or ultrasonic machining, which can accurately create complex shapes without damaging the material.

3. Required Surface Finish and Tolerances

The desired surface quality and dimensional tolerances of the ceramic component play a decisive role. Methods like grinding and polishing are suited for applications needing high surface smoothness and precision. For less stringent tolerance requirements, more economical methods might be adequate.

4. Production Volume

The scale of production influences the choice of machining method as well. High-volume production might benefit from methods that, while expensive to set up, provide faster machining times and lower per-unit costs at scale, such as laser cutting or automated grinding.

5. Thermal and Mechanical Stress

Ceramics are sensitive to thermal shock and mechanical stress, which can induce cracking and other defects. Techniques that minimize these stresses during machining are preferred, particularly for high-performance applications in aerospace and electronics.

Table 3: Factors Influencing the Selection of Ceramic Cutting Methods

| Factor | Influence on Technique Choice | Recommended Techniques |

|---|---|---|

| Material Hardness | Dictates the robustness required of the tool | Diamond, CBN for harder materials; Carbide for softer materials |

| Component Design | Complexity may require precise techniques | Laser cutting, ultrasonic machining for intricate designs |

| Production Volume | High volume may favor faster, repeatable methods | Automated grinding or laser cutting for efficiency at scale |

| Thermal and Mechanical Stress | Need methods that minimize stress on materials | Laser cutting, ultrasonic machining to reduce mechanical stress |

V. Case Studies and Applications

To illustrate the practical application of the various ceramic cutting techniques discussed, here are some case studies from different industries that demonstrate the strategic use of these methods:

Aerospace Industry: High-Precision Components

- Technique Used: Laser Cutting and Ultrasonic Machining

- Application: Manufacturing components for jet engines and spacecraft, where precision and resistance to high temperatures are crucial. Laser cutting is used to create intricate, lightweight designs that reduce overall weight without compromising strength. Ultrasonic machining is employed for materials that are too brittle for conventional cutting methods, allowing for the creation of complex geometrical shapes with smooth finishes.

- Outcome: The components made using these techniques not only meet stringent aerospace standards but also contribute to enhanced performance and fuel efficiency of aerospace vehicles.

Electronics Industry: Semiconductor Fabrication

- Technique Used: Grinding and Polishing

- Application: Production of ceramic substrates used in semiconductor chips, where surface smoothness and dimensional accuracy are paramount. Precision grinding is used to achieve the initial shape and size, followed by polishing to create a highly smooth surface that ensures effective electrical insulation and heat dissipation.

- Outcome: The high-quality ceramic substrates produced are integral in preventing electrical failures and overheating in electronic devices, leading to more reliable and longer-lasting products.

Medical Devices: Bioceramics in Prosthetics

- Technique Used: Diamond Tooling Grinding

- Application: Fabrication of bioceramic components used in dental and orthopedic implants. The extreme hardness and wear resistance of ceramics make them ideal for joint replacements and dental prosthetics. Diamond tooling is used to achieve the precision cuts and smooth finishes required for these implants to be compatible with human tissue.

- Outcome: The resulting bioceramic implants offer superior durability and compatibility with body tissues, reducing the risk of rejection and improving the longevity of the implants.

Automotive Industry: Wear-Resistant Components

- Technique Used: Electrical Discharge Machining (EDM)

- Application: Creating complex shapes in silicon carbide ceramic materials used for high-wear components such as valves and bearings. EDM is chosen for its ability to handle very hard materials and maintain tight tolerances without inducing stress fractures.

- Outcome: The ceramic components produced are exceptionally wear-resistant and capable of withstanding the harsh conditions of automotive engines, leading to longer component lifespans and reduced maintenance costs.

Table 4: Case Studies of Ceramic Cutting Techniques in Industry

| Industry | Technique Used | Application Description | Outcome |

|---|---|---|---|

| Aerospace | Laser Cutting, Ultrasonic Machining | Manufacturing lightweight, precision components | Enhanced performance, reduced aircraft weight |

| Electronics | Grinding, Polishing | Ceramic substrates for semiconductor chips | Improved electrical insulation and heat dissipation |

| Medical Devices | Diamond Tooling Grinding | Bioceramic components for implants | Improved compatibility with human tissue, durability |

| Automotive | Electrical Discharge Machining (EDM) | High-wear ceramic components like valves | Increased component lifespan, reduced maintenance costs |

VI. Conclusion

The exploration of ceramic cutting techniques underscores the critical role these methods play in the manufacturing and finishing of ceramic components across diverse industries. As we've seen, the selection of an appropriate cutting method hinges on multiple factors including the hardness and britleness of the material, the complexity of the component design, the required surface finish, production volume, and sensitivity to thermal and mechanical stress. Each cutting technique, from precision laser cutting to robust grinding and ultrasonic machining, offers unique benefits tailored to specific applications.

Looking ahead, the future of ceramic cutting is likely to see further innovations and advancements. Continued improvements in laser technology, ultrasonic equipment, and abrasive materials are expected to enhance efficiency and precision. Additionally, integration with suppliers like Advanced Ceramic Materials (ACM) can provide access to a broad spectrum of high-quality ceramics tailored for specific cutting needs, enhancing the overall efficacy of the machining processes.

By staying informed about these technologies and understanding their practical applications through case studies, manufacturers can make well-informed decisions that optimize their operations and lead to superior ceramic products. The ongoing evolution of ceramic cutting techniques will undoubtedly continue to play a pivotal role in meeting the ever-growing demands of high-performance, high-precision ceramic components in global industries.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}