Key Advanced Ceramics: Titanium Carbide and Other High-Performance Materials

Introduction

Advanced ceramics, also known as high-performance or technical ceramics, are materials engineered for exceptional properties that surpass those of traditional ceramics. These materials exhibit superior mechanical strength, thermal stability, electrical conductivity, and chemical resistance, making them indispensable in modern industrial and high-tech applications.

Advanced ceramics are pivotal in aerospace, electronics, medical devices, and energy sectors, where performance and reliability are critical. This article provides a comprehensive overview of titanium carbide (TiC) and other key advanced ceramics, exploring their physical and chemical properties, preparation methods, and diverse applications.

Titanium Carbide (TiC)

Physical Properties

Titanium carbide is renowned for its exceptional physical properties:

- High Melting Point: Approximately 3,230°C, making it suitable for high-temperature applications.

- Outstanding Hardness and Wear Resistance: TiC ranks high on the Mohs scale, providing excellent durability in abrasive environments.

- Excellent Electrical and Thermal Conductivity: Facilitates efficient performance in electronic and thermal management applications.

Wyckoff (1963) Crystal Structures - Second Edition, Volume 1. John Wiley, New York.

Chemical Properties

Titanium carbide exhibits remarkable chemical stability:

- High Corrosion Resistance: Resistant to oxidation and chemical degradation in harsh environments.

- Stability in Extreme Conditions: Maintains structural integrity under high temperatures and corrosive atmospheres.

Preparation Methods

Several methods are employed to synthesize titanium carbide:

- Melting: Involves the fusion of titanium and carbon sources at elevated temperatures to form TiC.

- Chemical Vapor Deposition (CVD): A process where gaseous precursors react on a substrate to deposit TiC films with precise control over composition and structure.

Applications

Titanium carbide's unique properties make it versatile across various industries:

- Cutting Tools and Wear-Resistant Components: Utilized in machining and tooling applications to enhance longevity and performance.

- Electronic Devices and Semiconductor Industry: Employed in electrodes and components due to its excellent electrical conductivity.

- High-Temperature Structural Materials: Used in environments requiring materials that can withstand extreme heat without degradation.

- Decorative Materials: Leveraged for aesthetic coatings that benefit from TiC's metallic luster and durability.

Other Key Advanced Ceramics

-

Silicon Nitride (Si₃N₄)

- Properties: High strength, excellent thermal stability, and resistance to thermal shock.

- Applications: Engine components, bearings, cutting tools, and turbine blades.

-

Aluminum Oxide (Al₂O₃)

- Properties: High hardness, good electrical insulation, and excellent wear resistance.

- Applications: Electronic substrates, optical lenses, cutting tools, and biomedical implants.

-

Zirconia (ZrO₂)

- Properties: High toughness, excellent fracture resistance, and thermal insulation.

- Applications: Dental implants, refractory materials, fuel cells, and sensors.

-

Silicon Carbide (SiC)

- Properties: High thermal conductivity, exceptional wear resistance, and chemical stability.

- Applications: Abrasives, semiconductor devices, automotive brake systems, and heating elements.

-

Aluminum Nitride (AlN)

- Properties: High thermal conductivity, good electrical insulation, and thermal expansion compatibility with electronics.

- Applications: Electronic heat sinks, LED packaging, and microwave devices.

-

Boron Silicide (BxSiy)

- Properties: High hardness, excellent high-temperature stability, and good electrical conductivity.

- Applications: Refractory materials, cutting tools, and specialized electronic components.

-

Titanium Nitride (TiN)

- Properties: High hardness, excellent wear and corrosion resistance, and attractive gold-like appearance.

- Applications: Decorative coatings, tool coatings, and electronic components.

-

Niobium Nitride (NbN)

- Properties: Superconducting properties, high melting point, and chemical stability.

- Applications: Superconducting magnets, electronic circuits, and thin-film resistors.

-

Tantalum Nitride (TaN)

- Properties: High hardness, excellent chemical and thermal stability, and good electrical conductivity.

- Applications: Electronic thin films, hard coatings, and microelectromechanical systems (MEMS).

-

Tungsten Carbide (WC)

- Properties: Extremely high hardness, superior wear resistance, and good toughness.

- Applications: Cutting tools, mining machinery, milling equipment, and molds.

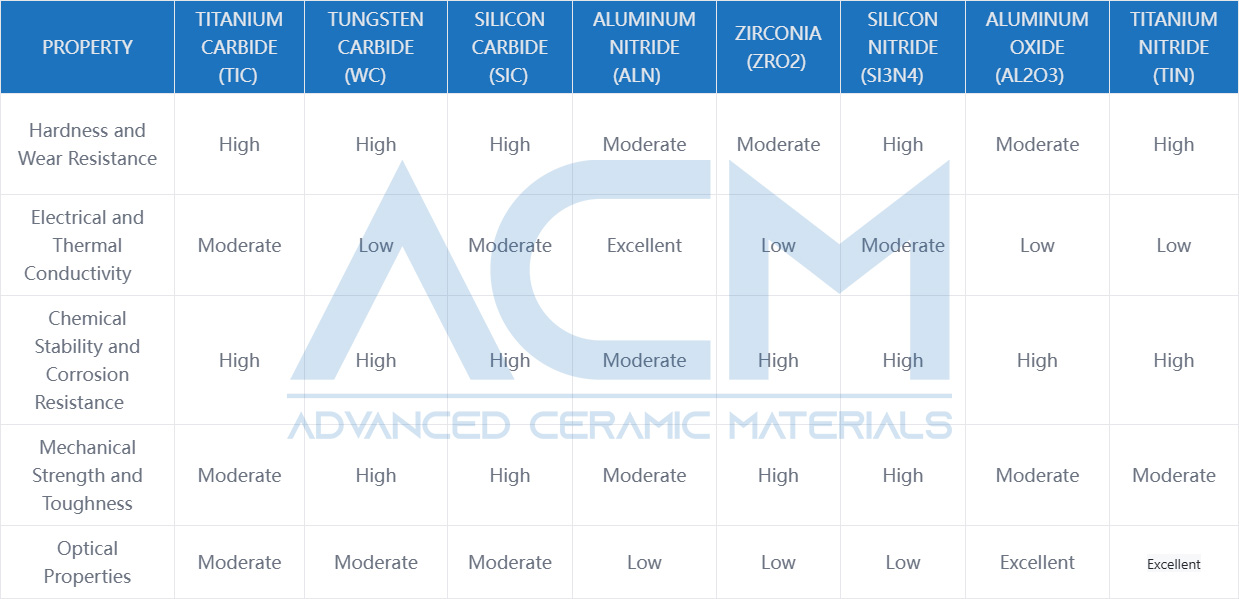

Performance Comparison of Various Ceramics

Understanding the distinct properties of each advanced ceramic is crucial for selecting the appropriate material for specific applications:

- Hardness and Wear Resistance: Titanium carbide, tungsten carbide, and silicon carbide exhibit the highest hardness and wear resistance, making them ideal for cutting and abrasive applications.

- Electrical and Thermal Conductivity: Aluminum nitride and titanium carbide offer excellent electrical and thermal conductivity, suitable for electronic and thermal management applications.

- Chemical Stability and Corrosion Resistance: Silicon carbide and titanium carbide demonstrate outstanding chemical stability, essential for use in corrosive environments.

- Mechanical Strength and Toughness: Silicon nitride and zirconia possess high mechanical strength and fracture resistance, suitable for structural and high-stress applications.

- Optical Properties: Aluminum oxide and titanium nitride are preferred for optical and decorative applications due to their excellent optical properties and aesthetic appeal.

Preparation Methods

Advanced ceramics are synthesized using various sophisticated techniques tailored to achieve desired properties:

-

Powder Metallurgy: Involves the blending, pressing, and sintering of ceramic powders to form dense, high-performance components. Advantages include precise control over composition and microstructure, while limitations include potential porosity and the need for high-temperature processing.

-

Chemical Vapor Deposition (CVD): A process where gaseous reactants form a solid ceramic deposit on a substrate. This method allows for high purity, uniform coatings, and the ability to fabricate complex shapes but can be costly and require specialized equipment.

-

Hot Pressing: Combines pressure and temperature to densify ceramic powders, enhancing mechanical properties. It offers improved density and uniformity but may be limited by the size and shape of the components.

-

Other Advanced Techniques:

- Combustion Synthesis: Utilizes exothermic reactions to produce ceramics quickly and efficiently.

- Plasma Sintering: Applies plasma to achieve rapid densification and fine-grained structures.

- Spark Plasma Sintering (SPS): Uses pulsed electric current to sinter ceramics rapidly, minimizing grain growth and enhancing properties.

Application Cases

Advanced ceramics find applications across a multitude of industries due to their superior properties:

Industrial Applications

- Cutting Tools and Molds: Titanium carbide and tungsten carbide are extensively used in cutting tools and molds due to their unmatched hardness and wear resistance, enabling precise and long-lasting performance in machining processes.

Aerospace

- High-Temperature Structural Components: Silicon nitride and zirconia are employed in engine parts and thermal barrier coatings, providing the necessary strength and thermal stability to withstand extreme operational conditions.

- Thermal Protection Systems: Advanced ceramics are integral to heat shields and thermal barriers, protecting aerospace vehicles from intense heat during re-entry and high-speed flight.

Electronics and Semiconductors

- Insulating Substrates and Heat Sinks: Aluminum nitride and silicon carbide are used in electronic substrates and heat sinks to manage heat dissipation efficiently, ensuring the reliability and longevity of electronic devices.

- Thin-Film Coatings: Titanium nitride and tantalum nitride are utilized in thin-film coatings for their conductive and protective properties, enhancing the performance of microelectronics and MEMS devices.

Medical Devices

- Dental Implants and Tools: Zirconia and aluminum oxide are favored in dental applications for their biocompatibility, aesthetic appeal, and strength, providing reliable and durable solutions for dental restorations and tools.

- Surgical Instruments: Advanced ceramics offer superior wear resistance and sterilization capabilities, making them ideal for precision surgical instruments that require high performance and longevity.

Energy and Environment

- Catalyst Supports and Battery Materials: Boron silicide and silicon carbide serve as catalyst supports and components in batteries, contributing to efficient energy conversion and storage systems.

- Environmental Sensors and Filtration: Advanced ceramics are used in sensors and filtration systems to monitor and purify environmental pollutants, leveraging their chemical stability and durability.

Conclusion

Advanced ceramics, including titanium carbide and other high-performance materials, play a critical role in modern technology and industry. Their exceptional properties—ranging from extreme hardness and thermal stability to superior electrical conductivity and chemical resistance—enable innovative solutions across diverse applications. The continual advancement and integration of these materials into various sectors underscore their importance in driving technological progress. As industries demand ever-higher performance standards, the development and application of advanced ceramics will remain pivotal. Ongoing research focuses on enhancing the properties of existing ceramics, developing new composite materials, and improving manufacturing techniques. Innovations in nanostructured ceramics, smart ceramics with self-healing capabilities, and environmentally friendly fabrication processes are expected to further expand the applications and performance of advanced ceramics, solidifying their role as essential materials in the future technological landscape.

Overall, the choice of advanced ceramic materials depends on the specific requirements of the application, and companies like Advanced Ceramic Materials (ACM) provide specialized solutions to meet diverse industrial needs with high-performance ceramics.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments