Pyrolytic Boron Nitride & Pyrolytic Graphite in High-Temperature Applications

High-temperature applications demand materials that can withstand extreme conditions without losing structural integrity or functionality. Pyrolytic boron nitride (PBN) and pyrolytic graphite (PG) have emerged as leaders in this domain. Both materials boast exceptional thermal properties, making them indispensable in industries ranging from aerospace to electronics. This article explores the applications and future potential of pyrolytic boron nitride and pyrolytic graphite in high-temperature environments.

Joint Applications in High-Temperature Environments

Aerospace Engineering

In aerospace, the extreme conditions encountered during flight and re-entry necessitate materials that can withstand high temperatures and corrosive environments. Both PBN and PG are used in aerospace engineering for their unique properties:

- Heat Shields: PG’s remarkable thermal conductivity and stability make it ideal for heat shields in spacecraft, efficiently dissipating heat to protect sensitive components.

- Insulators and Heat Shields: PBN is used for its thermal insulation and chemical stability, ensuring that components exposed to high temperatures and corrosive environments maintain their integrity and performance.

Semiconductor Manufacturing

The semiconductor industry benefits significantly from the properties of both PBN and PG:

- Crystal Growth Crucibles: PBN is used in crucibles for semiconductor crystal growth due to its high purity and thermal stability, ensuring contamination-free environments essential for high-performance electronic components.

- Wafer Production: PG’s excellent thermal properties ensure uniform heating during the semiconductor wafer manufacturing process, which is vital for the precision required in semiconductor fabrication.

High-Power Electronics

As electronic devices become more powerful, efficient thermal management becomes critical:

- Heat Spreaders: PG serves as a heat spreader in high-power electronics, effectively dissipating heat generated by electronic components to prevent overheating and ensure longevity and reliability.

- Electrical Insulation: PBN’s superb electrical insulation properties allow it to function at high temperatures without degrading, making it ideal for electronic applications requiring high thermal stability.

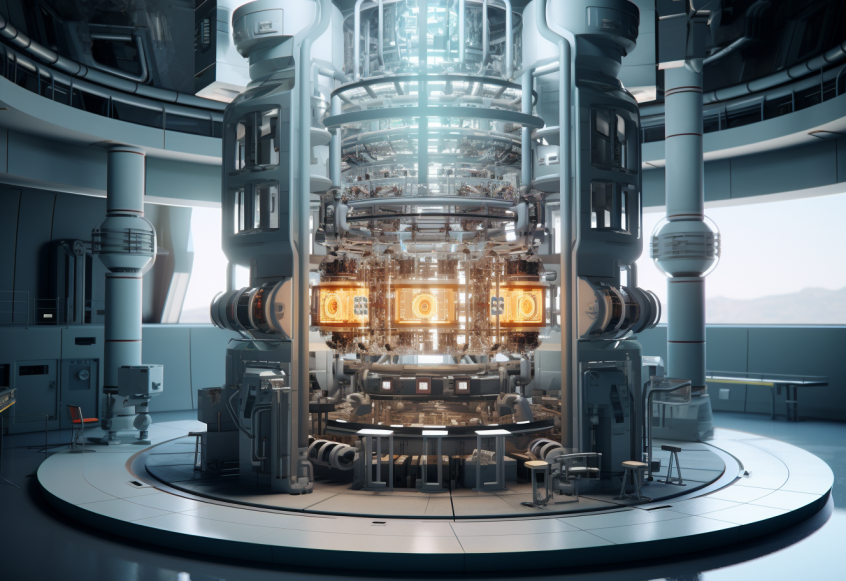

Nuclear Reactor Components

Nuclear reactors require materials that can endure intense heat and radiation:

- Reactor Components: Both PBN and PG are used in nuclear reactors. PG’s stability at high temperatures makes it suitable for reactor cores, while PBN’s chemical stability and thermal insulation properties ensure the safe and efficient operation of various reactor components.

Medical Devices

In the medical field, high-temperature materials are crucial for certain applications:

- High-Temperature Sterilization: PBN is used in medical devices requiring high-temperature sterilization processes due to its biocompatibility and thermal stability.

- Medical Implants: PBN's thermal stability also makes it suitable for the production of certain medical implants that must endure extreme conditions without degrading.

Microwave and RF Applications

PBN and PG play critical roles in microwave and radio frequency (RF) engineering:

- Microwave Components: PBN’s dielectric properties and thermal stability make it ideal for components such as substrates and windows in microwave devices, which must operate efficiently at high temperatures.

- Thermal Management in RF Devices: PG’s ability to dissipate heat efficiently ensures that RF devices maintain optimal performance without overheating.

Future Prospects and Innovations

Advances in Material Engineering

The future of high-temperature applications will likely see further advancements in the engineering of pyrolytic boron nitride and pyrolytic graphite. Researchers are exploring ways to enhance these materials' properties, such as increasing the thermal conductivity of PG or improving the thermal shock resistance of PBN. Nanotechnology may play a crucial role, with the incorporation of nanostructures potentially leading to materials with unprecedented thermal and mechanical properties.

Sustainable Manufacturing Processes

As industries push towards sustainability, the production processes for PBN and PG are also evolving. Innovations in manufacturing aim to reduce energy consumption and minimize environmental impact. Techniques such as chemical vapor deposition (CVD) are being refined to produce higher-quality materials more efficiently, with a focus on reducing waste and improving yield.

Integration with Emerging Technologies

The integration of pyrolytic boron nitride and pyrolytic graphite with emerging technologies is set to expand their applications further:

- Advanced Electronics: As electronic devices become more powerful, the demand for efficient thermal management solutions like PG will grow. PBN's electrical insulation properties will also be crucial in the development of next-generation electronic components.

- Space Exploration: The ongoing exploration of extreme environments in space will benefit from the thermal stability and durability of PBN and PG. These materials will be integral to the development of spacecraft capable of withstanding the harsh conditions of space travel.

- Energy Sector: In the quest for clean and efficient energy, materials that can withstand high temperatures and corrosive environments, such as PBN, will be essential. They will play a role in advanced nuclear reactors, fuel cells, and other high-temperature energy systems.

Conclusion

Pyrolytic boron nitride and pyrolytic graphite are at the forefront of materials science, offering solutions to some of the most demanding high-temperature applications. Their exceptional thermal properties, coupled with advancements in material engineering, position them as critical components in the future of industries ranging from aerospace to electronics. As research and development continue, these materials will undoubtedly play a pivotal role in navigating the challenges of high-temperature environments, driving innovation and technological progress forward.

Advanced Ceramic Materials (ACM), a leading supplier of PBN ceramics, exemplifies the industry's commitment to providing high-quality materials that meet the rigorous demands of these advanced applications. ACM's expertise in producing reliable and durable pyrolytic boron nitride products ensures that industries have access to the materials they need to push the boundaries of technology and performance. With suppliers like ACM, the future of high-temperature applications looks brighter and more promising than ever.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments