Do you have any questions? Email Us

[email protected]

PBN Crucibles for Precision Application

Pyrolytic Boron Nitride Crucible can withstand high temperatures in a high vacuum environment. It has excellent thermal conductivity, corrosion resistance, and electrical resistance.

READ MORE >

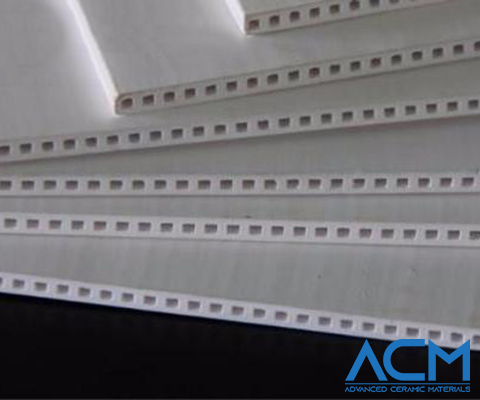

CM3236 Alumina Based Flat Sheet Ceramic Membrane

Alumina Based Flat Sheet Ceramic Membrane Description

Alumina Based Flat Sheet Ceramic Membrane is the core component of MBR. A membrane bioreactor (MBR) is high-efficiency sewage treatment equipment widely used in engineering practice and developed in recent years. Hollow flat sheet ceramic membranes can effectively solve the existing problems of engineering applications in hollow fiber membranes and organic plate membranes such as short service life, susceptibility to acid and alkali corrosion, etc.

Alumina Based Flat Sheet Ceramic Membrane Specifications

Advantages of Alumina-Based Flat Sheet Ceramic Membrane:

-Excellent resistance to acid/alkaline and oxidation chemicals;

-Solvent stability;

-High thermal stability;

-Fine separability with narrow pore size distribution;

-Excellent mechanical and abrasive resistance;

-Extremely long work life.

Technical Data of Alumina-Based Flat Sheet Ceramic Membrane:

| Technical Data | |

| Substrate Material | Al2O3 |

| Pore Size | 0.1-0.2 um |

| Pure Water Flux | 600-1200 L/m?*h*bar |

| Configuration | multiple options |

| Temperature resistance in air | -10 -150 °C |

| pH stability | 0-14* |

Alumina Based Flat Sheet Ceramic Membrane Applications

-Removal of suspended matter in wastewater after biochemical treatment.

-Solid-liquid separation in the industrial process:

- a) Separation and washing of pulp in hydrometallurgy

- b) Filtration of tungsten smelting wastewater before separation

- c) Solid-liquid separation of magnesium hydroxide slurry

- d) Solid-liquid separation of coal mine water.

-Pretreatment of reverse osmosis or nano-filtration process.

Alumina Based Flat Sheet Ceramic Membrane Packaging

Our Alumina Based Flat Sheet Ceramic Membrane is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 23661 Birtcher Dr. Lake Forest, CA 92630 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.