BN1811 Hot Pressed Boron Nitride Composite BN-SZ Ceramic, ZSBN

- Catalog No. BN1811

- Material BN+SiC+ZrO2

- Purity >99%

- Density 2.3-3.0 g/cm3

- Shape Customized

BN1811 Hot Pressed Boron Nitride Composite BN-SZ Ceramic, ZSBN

Composite Ceramic BN-SZ Description

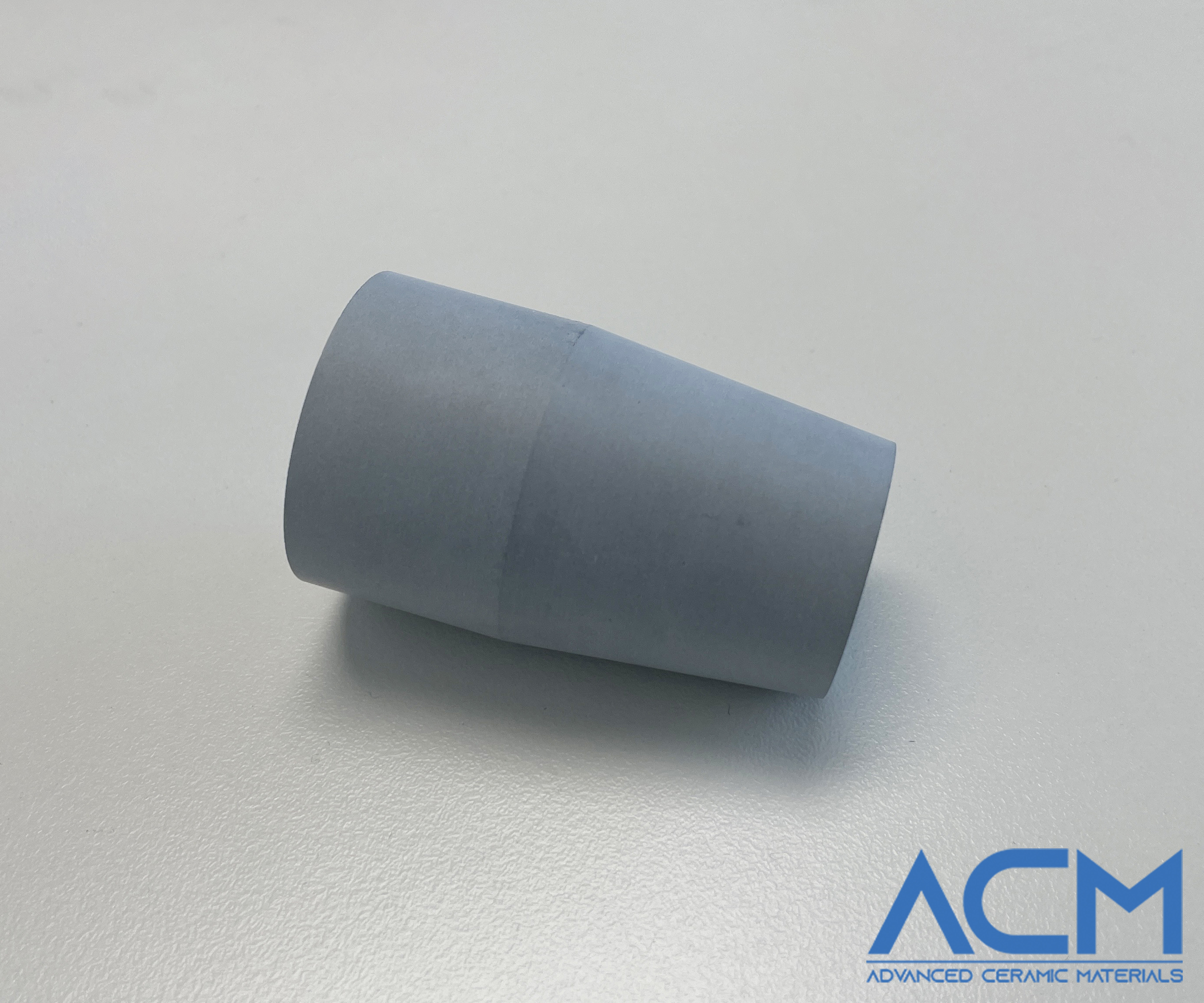

Boron Nitride is a kind of advanced synthesis ceramic that was sintered at a high temperature and high pressure by BN powder. It has many excellent properties including high-temperature resistance, high thermal conductivity, easy machining, and good lubricity, making BN an outstanding material.

Boron nitride composite ceramic BN-SZ, using silicon carbide and zirconia as a bonding agent, improves the thermal shock resistance and wear resistance of the product. It is commonly used as a separate ring for horizontal continuous casting and a nozzle made of amorphous ribbon. These products have stable chemical properties, high thermal shock resistance, and high corrosion resistance. They are widely used in molten metal contact.

Chemical stability

Good wear resistance

High thermal shock stability

Composite Ceramic BN-SZ Specifications

| Grade | BN-SZ |

| Compositions | BN+SiC+ZrO2 |

| Density | 2.3-3.0 g/cm3 |

| 25°C Volume Resistivity | >10^12 Ω·cm |

| Max. Service Temp. (°C) | 900 (Oxygen) |

| 1700 (Inert Gas) | |

| 1700 (High Vacuum) | |

| Flexural Strength | 100 Mpa |

| Compressive Strength | 300 Mpa |

| Coefficient of Thermal Expansion (25-1000°C) | 4.0 10^-6/K |

| Thermal Conductivity | 40 W/mK |

Composite Ceramic BN-SZ Applications

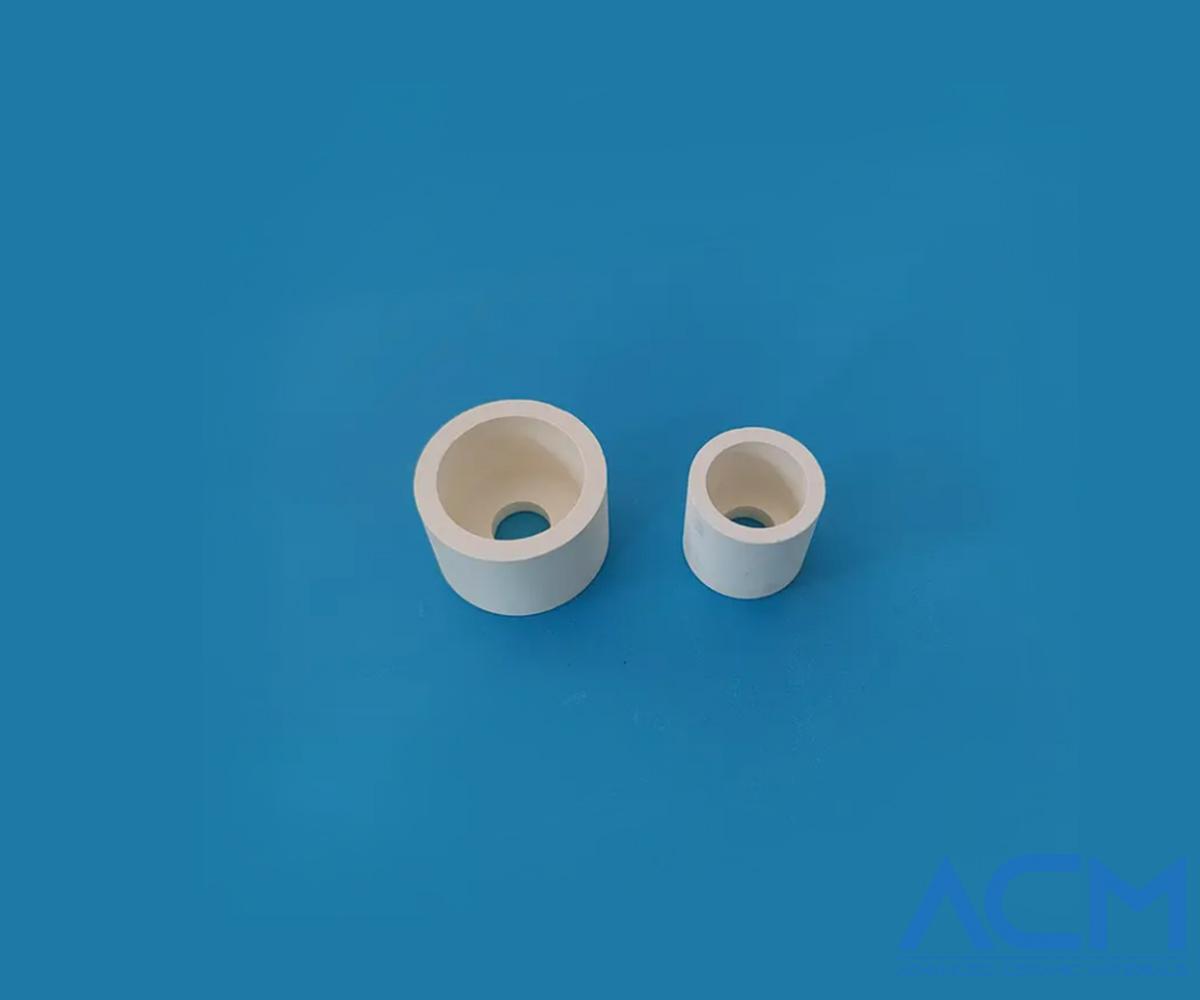

Used as a horizontal continuous casting separation ring

Used as metallurgical atomization and powder metallurgy atomizing nozzle

Used as a thin strip continuous casting side sealing board

Widely used in the contact of various molten metals

Packaging

Our Boron Nitride Ceramic BN-SZ is always carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

-

Attachment (Optional)

No file chosen