Zirconia Stabilized Boron Nitride (ZSBN)

Zirconia Stabilized Boron Nitride (ZSBN) is a composite material that marries the superior thermal and chemical stability of boron nitride (BN) with the enhanced toughness and thermal resistance of zirconia (ZrO2). By integrating the distinctive properties of boron nitride, such as high thermal conductivity and electrical insulation, with the mechanical strength and fracture toughness provided by zirconia, ZSBN emerges as a material exceptionally suited for demanding applications. This synergy results in a composite that not only withstands high temperatures and corrosive environments but also excels in thermal management and electrical insulation, making it a prime choice for advanced engineering solutions.

The properties of ZSBN encompass enhanced mechanical strength and toughness, thanks to the zirconia content, making it more resistant to wear and mechanical shock than pure boron nitride. Furthermore, it retains the high thermal conductivity characteristic of boron nitride, ensuring efficient heat dissipation. Its excellence in thermal shock resistance is attributed to the thermal stability of zirconia, while its chemical inertness against most chemicals and molten metals is retained from boron nitride. Additionally, ZSBN's electrical insulation properties make it ideal for a wide range of electronic applications, where these combined properties are essential for performance and durability.

More Info About ZSBN

Products | Properties | Specification | Applications | Video | FAQs

Zirconia Stabilized Boron Nitride Properties

Zirconia Stabilized Boron Nitride (ZSBN) is a composite material that leverages the unique advantages of both boron nitride and zirconia, resulting in a set of enhanced properties suitable for high-performance and high-temperature applications. Here are the key properties of ZSBN:

- Enhanced Mechanical Strength: The inclusion of zirconia significantly improves the mechanical strength and toughness of boron nitride, making ZSBN more resistant to mechanical shock and wear.

- High Thermal Conductivity: ZSBN maintains the excellent thermal conductivity characteristic of boron nitride, facilitating effective heat dissipation, which is critical in applications requiring efficient thermal management.

- Superior Thermal Shock Resistance: The composite material exhibits exceptional resistance to thermal shock, a benefit attributed to the thermal stability of zirconia. This property is essential for materials used in environments experiencing rapid temperature changes.

- Chemical Inertness: ZSBN retains the chemical inertness of boron nitride, offering resistance to attack from most chemicals and molten metals. This makes it suitable for use in chemically aggressive environments.

- Excellent Electrical Insulation: Like boron nitride, ZSBN provides outstanding electrical insulation properties. This feature, combined with its thermal management capabilities, makes it highly suitable for electronic applications where electrical insulation is a critical factor.

- Low Thermal Expansion: The material exhibits low thermal expansion, similar to boron nitride, which minimizes dimensional changes and mechanical stress in response to temperature fluctuations.

- Good Metallization Compatibility: ZSBN can be effectively combined with metals through metallization processes, enhancing its utility in electronic packaging and device fabrication.

These properties make Zirconia Stabilized Boron Nitride a versatile material choice for a wide range of applications, including electronics, aerospace, industrial processing, and wherever high temperature, wear resistance, and thermal management are required.

Zirconia Stabilized Boron Nitride Specification

| Grade | BN-SZ |

| Compositions | BN+SiC+ZrO2 |

| Density | 2.3-3.0 g/cm3 |

| 25°C Volume Resistivity | >10^12 Ω·cm |

| Max. Service Temp. (°C) | 900 (Oxygen) |

| 1700 (Inert Gas) | |

| 1700 (High Vacuum) | |

| Flexural Strength | 100 Mpa |

| Compressive Strength | 300 Mpa |

| Coefficient of Thermal Expansion (25-1000°C) | 4.0 10^-6/K |

| Thermal Conductivity | 40 W/mK |

Zirconia Stabilized Boron Nitride Applications

Zirconia Stabilized Boron Nitride (ZSBN) combines the best of boron nitride's thermal and chemical stability with zirconia's mechanical toughness. This unique composite material finds applications across various high-demand sectors:

Electronics and Semiconductor Industry

ZSBN's exceptional electrical insulation and high thermal conductivity make it ideal for electronic packaging and as substrates in semiconductor devices. Its ability to efficiently dissipate heat is crucial for high-power electronic components, ensuring reliability and extended service life.

Aerospace and Defense

In aerospace and defense, ZSBN is used for components that require high thermal shock resistance and stability under extreme conditions. Its applications include thermal insulators, heat shields, and components within propulsion systems, where material performance is critical at high temperatures.

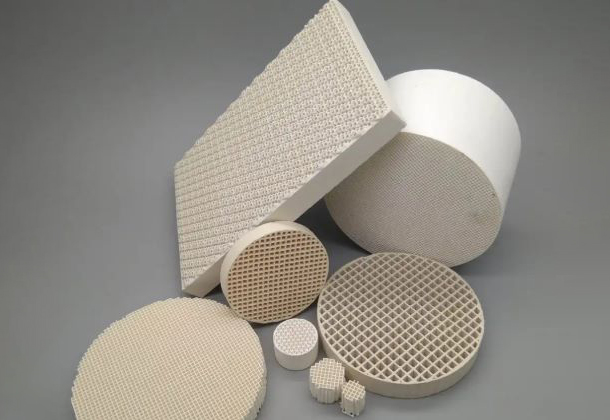

Industrial Processing

The material's resistance to chemical attack and thermal stability make it suitable for use in high-temperature industrial processes. ZSBN can be found in crucibles, nozzles, and other components that come into contact with molten metals, providing longevity and reliability.

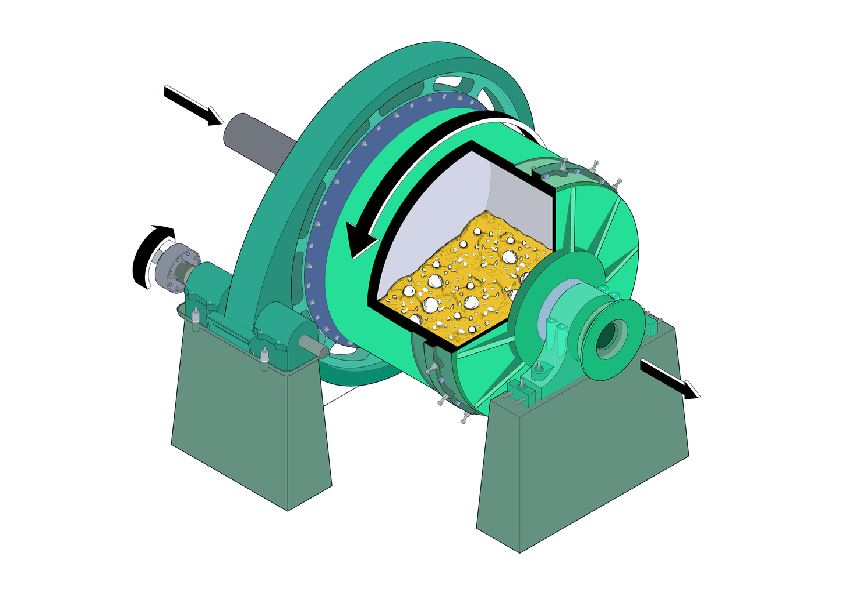

Cutting Tools and Abrasives

Leveraging its enhanced mechanical strength, ZSBN is used in the manufacture of cutting tools and abrasives for machining hard materials. Its wear resistance ensures tools maintain their edge and performance, reducing downtime and tool replacement costs.

Thermal Management Solutions

For applications requiring efficient thermal management, such as heat sinks and heat spreaders, ZSBN offers superior thermal conductivity. It's particularly beneficial in electronics cooling, where managing device temperature is key to operational efficiency and preventing overheating.

ACM Ceramic Product Video

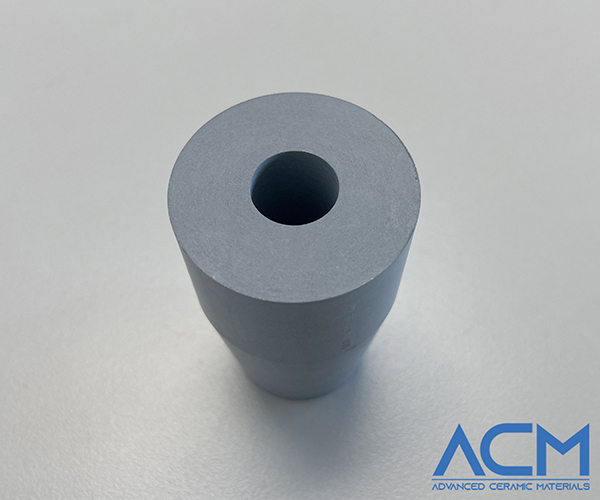

Your ZSBN Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of Zirconia Stabilized Boron Nitride (ZSBN) products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us with any questions about ZSBN or other ceramic materials that are not listed on the website.

| Chemical Formula | BN+SiC+ZrO2 |

| Mechanical | |

| Density | 2.3-3.0 g/cm3 |

| Hardness | 20-25 GPa |

| Modulus of Elasticity | 300-350 GPa |

| Flexural Strength | 100 Mpa |

| Compressive Strength | 300 Mpa |

| Poisson's Ratio | 0.21-0.22 |

| Fracture Toughness | 5-8 MPa m½ |

| Electrical | |

| Dielectric Strength | 10-20 kV/mm |

| Dielectric Constant | 4-6 |

| Volume Resistivity | 10^10 - 10^12 Ω·m |

| Thermal | |

| Coefficient of Thermal Expansion | 4.0 10^-6/K |

| Thermal Conductivity | 40 W/mK |

| Specific Heat | 0.5 J/g·K |

| Shock Resistance | - |

| Maximum Working Temperature | 1700℃ |