Do you have any questions? Email Us

[email protected]

PBN Crucibles for Precision Application

Pyrolytic Boron Nitride Crucible can withstand high temperatures in a high vacuum environment. It has excellent thermal conductivity, corrosion resistance, and electrical resistance.

READ MORE >

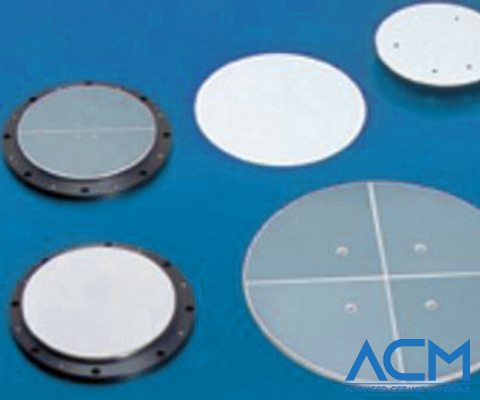

AL3258 Electrostatic Chuck (Al2O3, AlN, Sapphire)

Electrostatic Chuck Description

A built-in electrode is embedded, using the electrostatic force generated between the structure and the silicon wafer placed on the surface of the ESC. In the semiconductor manufacturing process, this type of product can be used for silicon wafer installation, flatness correction, and silicon wafer cooling.

Electrostatic Chuck Specifications

- Designed for φ200/300mm Equipment

- High-purity Al2O3/AlN/Sapphire material

- High plasma durability

- Good chucking/de-chucking response

- Withstand the extreme natural condition of some samples in both high and low temperature

| Material Item | Sapphire |

| Color | Transparent |

| Content (%) | 99.99 |

| Density (g/cm3) | 3.97 |

| Vickers Hardness HV9.807N (Gpa) | 22.5 |

| Young's Modulus (Gpa) | 470 |

| Compressive Strength (Mpa) | 2,940 |

| Thermal Conductivity (20℃) (W/(m·K) | 41 |

Electrostatic Chuck Applications

Electrostatic Chuck is used for silicon wafer installation, flatness correction, and silicon wafer cooling.

Electrostatic Chuck Packaging

Our Electrostatic Chuck is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 23661 Birtcher Dr. Lake Forest, CA 92630 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.