LA1409 Lanthanum Boride Powder, LaB6 Powder

- Catalog No. LA1409

- Molecular Formula LaB6

- Molecular Weight 203.78

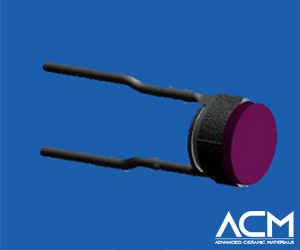

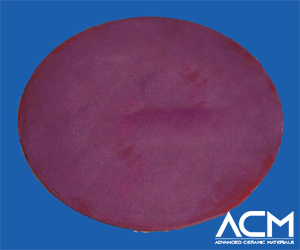

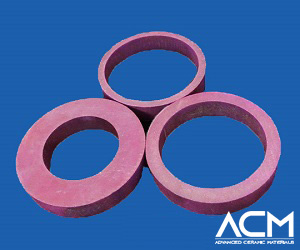

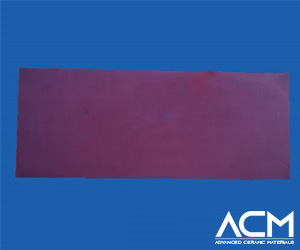

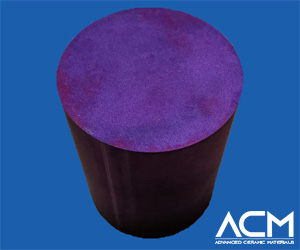

- Appearance Purple

- Melting Point 2210 °C

- Density 4.72 g/cm3

- Solubility in Water Insoluble

- Crystal Structure Cubic

Datasheet

Inquiry

LA1409 Lanthanum Boride Powder, LaB6 Powder

LaB6 Powder Description

Lanthanum Boride Powder (LaB6) is a high-performance ceramic material known for its exceptional properties, including:

- High Melting Point: 2210°C, enabling usage in high-temperature applications.

- Outstanding Electron Emissivity: Among the highest known, ideal for thermionic emission.

- Cubic Crystal Structure: Provides excellent thermal and mechanical stability.

- Insolubility: Stable in water and hydrochloric acid, making it highly durable in challenging environments.

These characteristics make LaB6 a preferred material for advanced applications in electron beam technologies, plasma devices, and material calibration.

LaB6 Powder Specifications

| Product | Lanthanum Hexaboride | Structure | Polycrystalline |

| Symbol | LaB6 | Thermal Conductive | 47 W/mK (20℃) |

| Cas No. | 12008-21-8 | Thermal Expansion | 6.2 10-6K-1 (20-900℃) |

| Atomic Mass | 203.78 g/mol | Electrical Resistance | ca.15 μΩ cm (20℃) |

| Density | 4.72 g/cm3 | Electrical Conductive | 6.65×104 S/cm (20℃) |

| Melting Point | 2528 K | Current Density | 150 A/cm2 (1950℃) |

| Hardness | 87.5 RA | Electron Emissivity | 2.6 eV |

| Flexure Strength (σ) | 200 Mpa | Fracture toughness (Kic) | 3.0 MN/m3/2 |

Custom particle sizes and specifications are available upon request.

LaB6 Powder Applications

-

Thermionic Emission: Fabrication of hot cathodes for electron tubes, ion beams, and gas pedals.

-

Plasma and Vacuum Technologies: Used in PECVD systems, vacuum electron beam welding machines, and electron beam lithography.

-

Imaging and Microscopy: Essential in SEM, TEM, and surface analysis devices for precise imaging.

-

Infrared and Optical Coatings: Applied as a coating for infrared filtering and optical devices.

-

Material Calibration: Used as a size/strain standard in X-ray powder diffraction for instrument calibration.

Packing and Storage

Advanced Ceramic Materials (ACM) ensures secure packaging and proper storage for all Lanthanum Boride Powder products:

- Standard Sizes: 5g, 25g, 100g, 500g, or customized upon request.

- Vacuum-Sealed Packaging: Maintains product purity and prevents contamination.

Store in a dry, cool environment, away from prolonged air exposure to ensure long-term quality.

Order Lanthanum Boride Powder Today

Contact us to learn more about Lanthanum Boride Powder (LaB6) or to request a custom quote. Our team of experts is here to help you find the ideal solution for your advanced applications.

Request a Quote

-

Attachment (Optional)

No file chosen