Do you have any questions? Email Us

[email protected]

PBN Crucibles for Precision Application

Pyrolytic Boron Nitride Crucible can withstand high temperatures in a high vacuum environment. It has excellent thermal conductivity, corrosion resistance, and electrical resistance.

READ MORE >

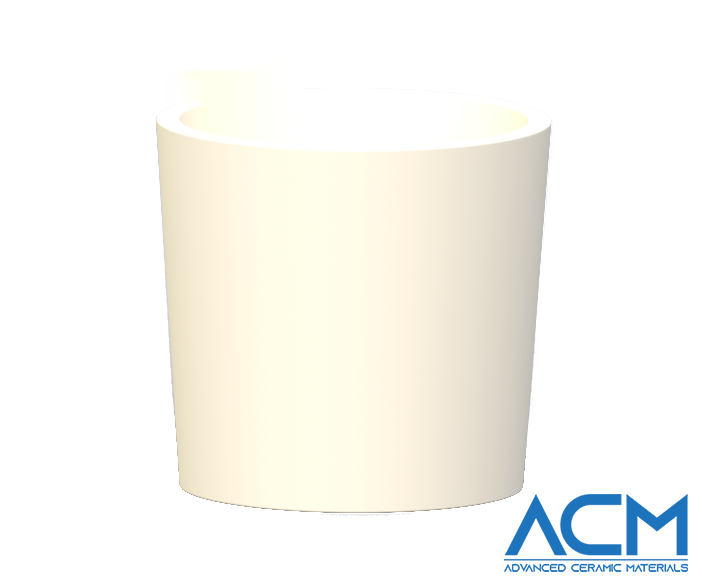

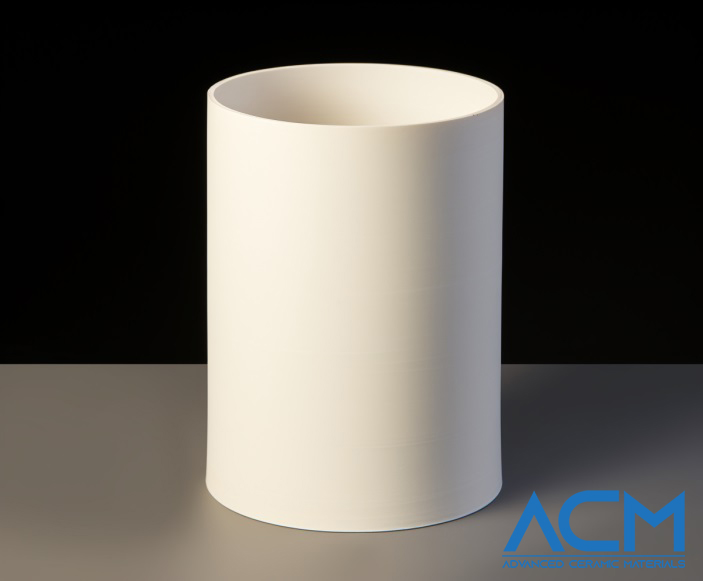

ZTA4694 Zirconia Toughened Alumina (ZTA) Rectangular Crucible

ZTA Rectangular Crucible Description

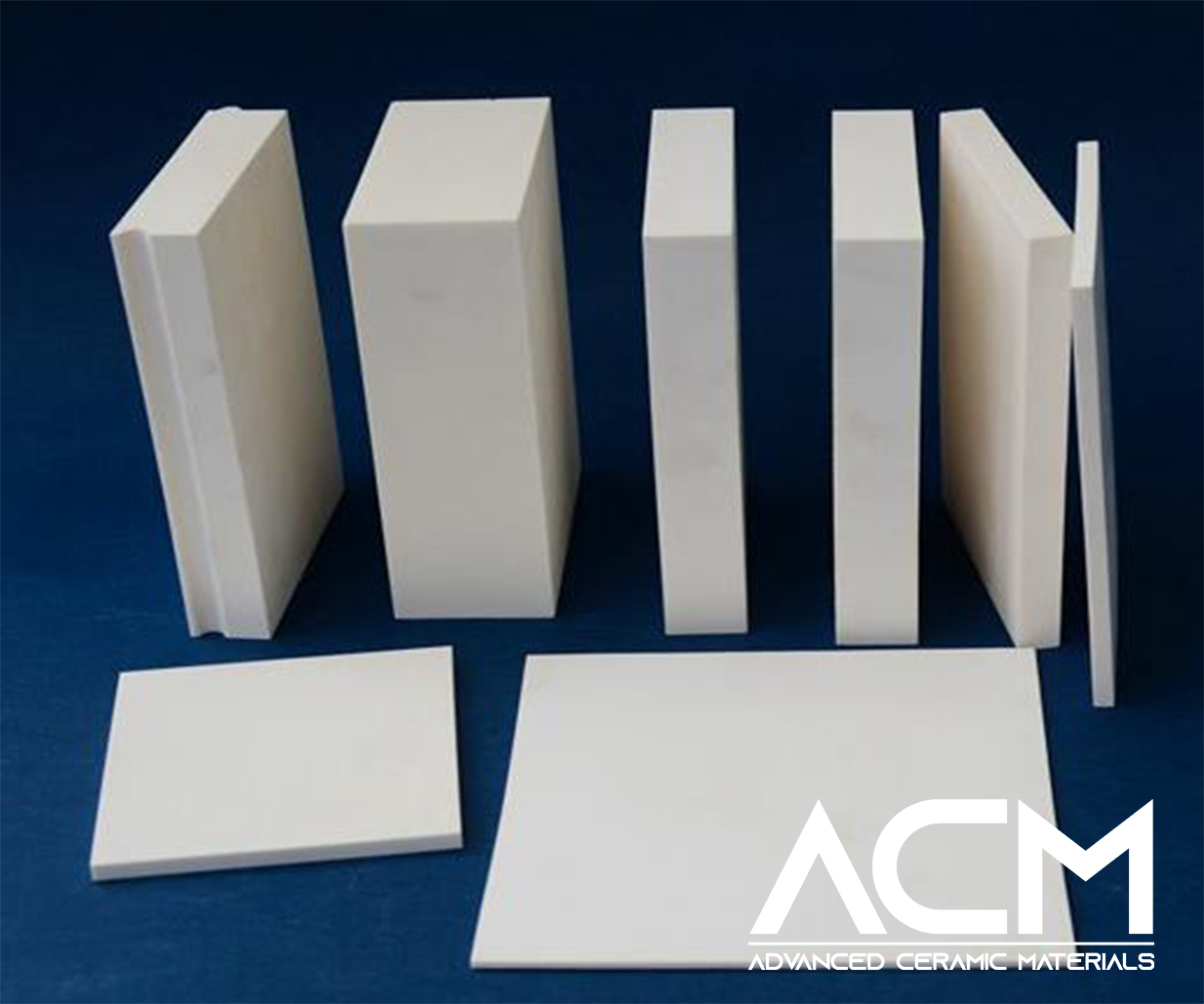

Zirconia Toughened Alumina (ZTA) Rectangular Crucible is a composite ceramic with excellent mechanical properties. It is produced by the addition of Zirconia to the main Alumina matrix before sintering. It combines the advantages of both materials, offering superior mechanical strength and abrasion resistance. Zirconia Toughened Alumina (ZTA) is stronger and tougher than ordinary alumina ceramic, and provides high thermal shock resistance, but costs less than zirconia. Additionally, ZTA crucibles exhibit a better surface finish than Alumina making them an excellent choice for bio-compatible and analytical grade applications.

ZTA Rectangular Crucible Specifications

Material Technical Properties

|

Max. Operating Temperature (℃) |

1600 |

|

Porosity % |

<0.5 |

|

Density g/cm3 |

4.1-4.38 |

|

Thermal Conductivity at 20˚C (W/mK) |

27 |

|

Coefficient of Thermal Expansion (10-6/℃) |

8.3 |

|

Dielectric Strength (AC-KV/mm) |

9.0 |

|

Dielectric Constant 1MHz |

11.0 |

|

Compressive Strength (MPa) |

2900 |

|

Flexural Strength (MPa) |

450 |

Typical ZTA Conical Crucible Specification

|

Top Outside Diameter |

20mm |

|

Top Inside Diameter |

13mm |

|

Wall Thickness |

1.5mm |

|

Internal Height |

10mm |

ZTA Rectangular Crucible Applications

Zirconia Toughened Alumina (ZTA) Rectangular Crucible is used in analytical applications, metals melting, heat treatment of ceramic powders, and material acid treatment even at elevated temperatures. ZTA Conical Crucibles are suitable for annealing, fusion processes, and crystal growing.

ZTA Rectangular Crucible Packaging

Our Zirconia Toughened Alumina (ZTA) Rectangular Crucible is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 23661 Birtcher Dr. Lake Forest, CA 92630 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.