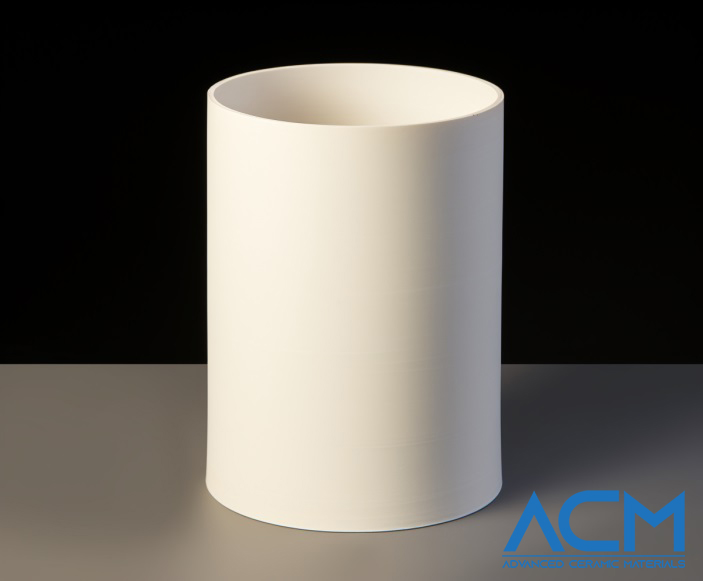

(Discontinued) ZTA4692 Zirconia Toughened Alumina (ZTA) Cylindrical Crucible

- Catalog No. ZTA4692

- Material Zirconia Toughened Alumina (ZTA)

- Density 4.1-4.38 g/cm3

- Color White

- Shape Cylindrical Crucible

- Maximum Operating Temperature 1600℃

Inquiry

(Discontinued) ZTA4692 Zirconia Toughened Alumina (ZTA) Cylindrical Crucible

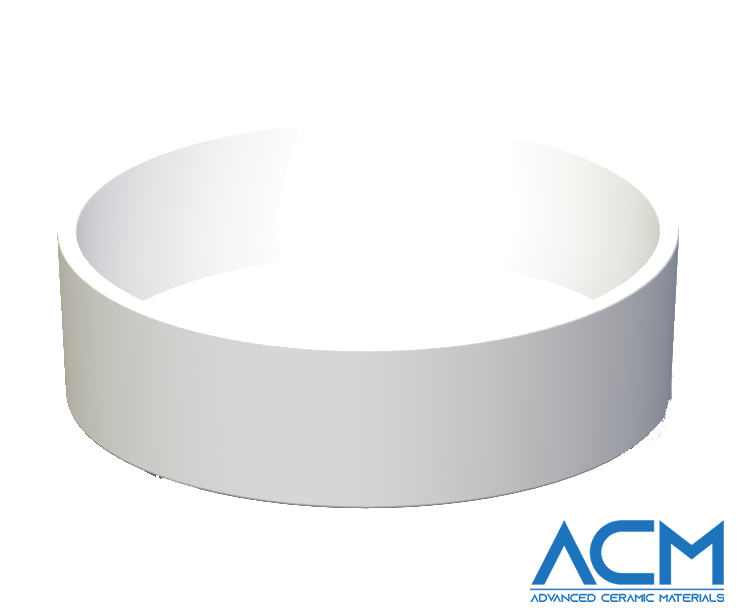

ZTA Cylindrical Crucible Description

The Zirconia Toughened Alumina (ZTA) Cylindrical Crucible is an advanced composite ceramic renowned for its exceptional mechanical properties. Crafted by introducing Zirconia into the primary Alumina matrix prior to sintering, it seamlessly combines the strengths of both materials, providing unparalleled mechanical strength and resistance to abrasion. Zirconia Toughened Alumina (ZTA) surpasses typical alumina ceramics in strength and toughness, offering heightened thermal shock resistance at a more economical price point than pure zirconia. Furthermore, ZTA crucibles showcase superior surface finish compared to Alumina, making them an ideal choice for applications requiring bio-compatibility and analytical precision.

ZTA Cylindrical Crucible Specifications

Material Technical Properties

|

Max. Operating Temperature (℃) |

1600 |

|

Porosity % |

<0.5 |

|

Density g/cm3 |

4.1-4.38 |

|

Thermal Conductivity at 20˚C (W/mK) |

27 |

|

Coefficient of Thermal Expansion (10-6/℃) |

8.3 |

|

Dielectric Strength (AC-KV/mm) |

9.0 |

|

Dielectric Constant 1MHz |

11.0 |

|

Compressive Strength (MPa) |

2900 |

|

Flexural Strength (MPa) |

450 |

Typical ZTA Conical Crucible Specification

|

Top Outside Diameter |

12mm |

|

Top Inside Diameter |

10mm |

|

Wall Thickness |

1mm |

|

Internal Height |

17mm |

ZTA Cylindrical Crucible Applications

The Zirconia Toughened Alumina (ZTA) Cylindrical Crucible is utilized in analytical applications, metals melting, heat treatment of ceramic powders, and material acid treatment, even at elevated temperatures. ZTA Conical Crucibles are well-suited for annealing, fusion processes, and crystal growing.

ZTA Cylindrical Crucible Packaging

Our Zirconia Toughened Alumina (ZTA) Cylindrical Crucible undergoes careful handling during storage and transportation to maintain the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen