Aluminum Silicate

Aluminium silicate refers to chemical compounds which are derived from aluminium oxide (Al2O3) and silicon dioxide (SiO2). The chemical formula of aluminum silicate is Al2SiO5, but aluminum silicate is often written as Al2O3·SiO2, because most silicates have very complex structures. Aluminium silicate is used in the manufacture of glass, ceramics, paints, printing inks, rubber, and plastics.

Read more: An Overview of Aluminium Silicate Ceramics

Aluminium Silicate Properties:

- Good dielectric and thermal insulation capabilities

- Resistant to heat, thermal shock, wear resistance, and corrosion resistance

- Low hygroscopicity

Aluminum Silicate Specification

|

Appearance |

Super white fine powder |

|

Sp. gravity |

2.70 - 2.80 |

|

PH Value |

8.0 - 8.5 |

|

Volatile matter |

max10.0°/0 |

|

Oil Absorption |

80 ± 5% |

|

Refractive Index |

1.58 |

|

Mhos hardness |

1 - 2 |

Aluminum Silicate Common Constituent Minerals

There are three common minerals composed of aluminum silicate, most of which are found in metamorphic rocks.

- Andalusite, belonging to the orthorhombic crystal system.

- Kyanite, belonging to the triclinic system

- Sillimanite, a variety of fine sillimanite, belongs to the orthorhombic crystal system.

The composition of these three ores is aluminum silicate, but their structure is different, so they are homogeneous and different crystals.

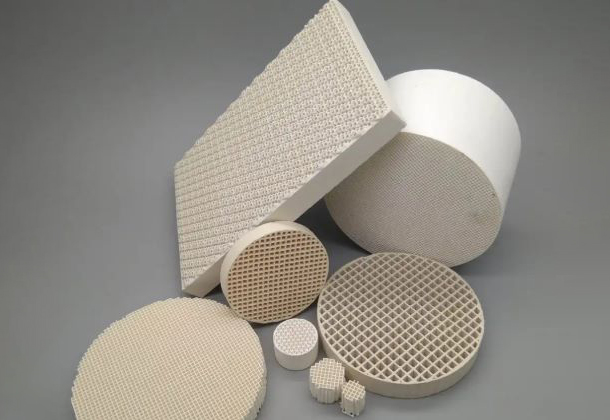

Aluminum Silicate Applications

- Filler for glass, pottery, paint, and paint;

- An ideal substitute for titanium dioxide and high-quality kaolin in coatings;

- Used to make heat-resistant, fire-proof, sound-proof, and heat-insulating cotton, boards, tubes, etc.

- Used as a filler for adhesives and sealants.

ACM Ceramic Product Video

Your Aluminum Silicate Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of aluminum silicate ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us for any questions about aluminum silicate or other ceramic materials that are not listed on the website.

| Chemical Formula | 3Al2O3·2SiO2(Mullite) |

| Mechanical | |

| Density | 2.3 g/cm3 |

| Hardness | 8-10 GPa |

| Modulus of Elasticity | 150-250 GPa |

| Flexural Strength | 64 MPa |

| Compressive Strength | 275 MPa |

| Poisson's Ratio | 0.23 |

| Fracture Toughness | 1.5-3 MPa m½ |

| Electrical | |

| Dielectric Strength | 3.9 dc kV/mm |

| Dielectric Constant | 5.3 (@ 1 MHz) |

| Volume Resistivity | >10^14 ohm-cm |

| Thermal | |

| Coefficient of Thermal Expansion | 5x10^-6/°C |

| Thermal Conductivity | 2-4 W/(m*K) |

| Specific Heat | - |

| Shock Resistance | - |

| Maximum Working Temperature | 1600°C |