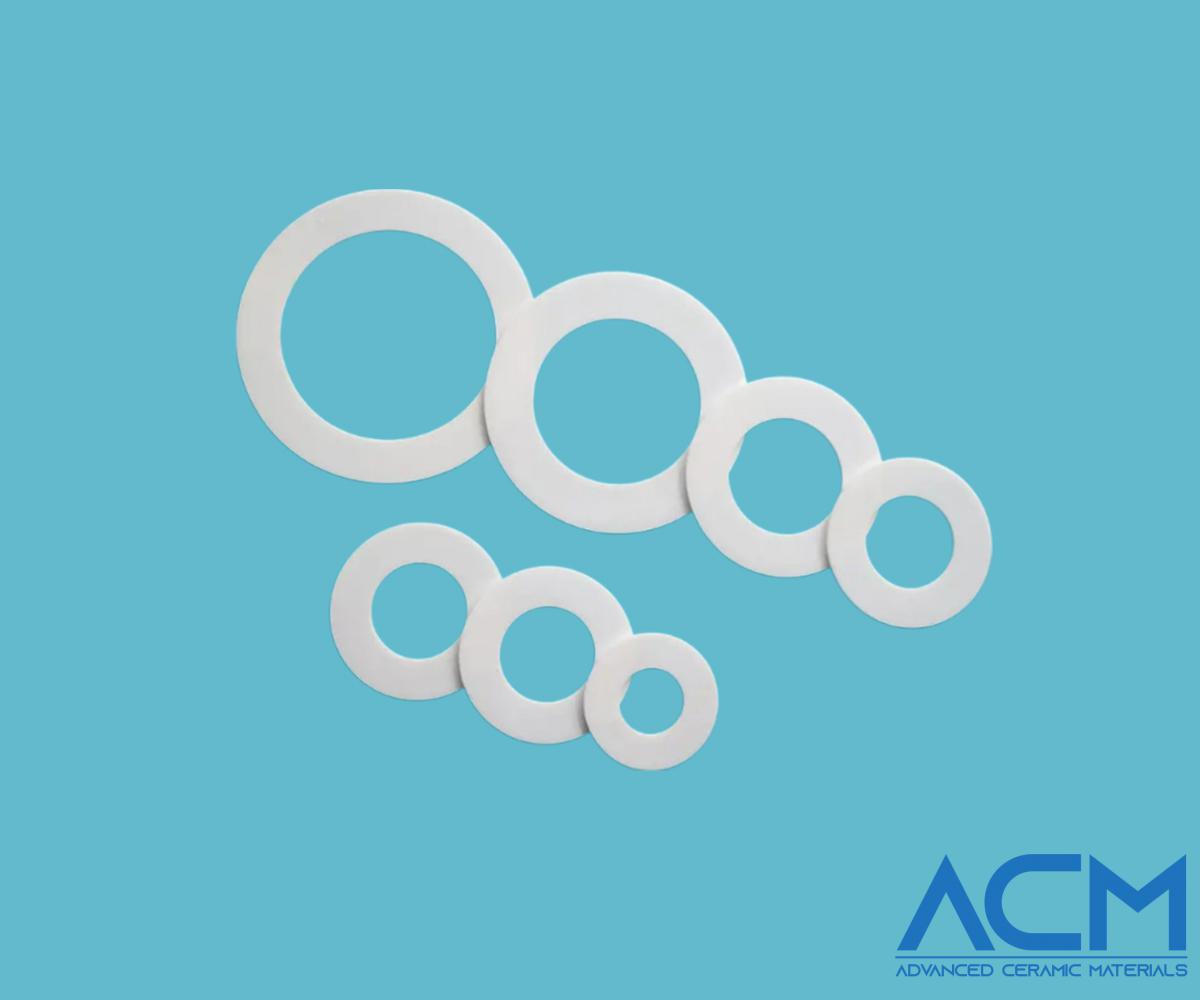

HBN0921 Hot Pressed Boron Nitride Ring, BN Ring

- Catalog No. HBN0921

- Chemical Formula BN

- Molecular Weight 24.82

- Appearance Appearance

- Melting Point 2973 °C

HBN0921 Hot Pressed Boron Nitride Ring, BN Ring

Hot Pressed Boron Nitride Ring Description

Boron nitride, also known as BN, Hexagonal boron nitride (H-BN), and hot-pressed boron nitride, is a good self-lubricating ceramic that can withstand high temperatures and maintain its lubricating capability in a high vacuum environment. Our Boron Nitride crucibles are made from a hot-pressed boron nitride blank. Hexagonal boron nitride (H-BN) behaves similarly to graphite mechanically but offers excellent electrical resistance.

Hot Pressed Boron Nitride Ring Advantages

- Low wetability to molten metal

- Relatively high thermal conductivity with low thermal expansion

- Relatively high thermal shock resistance

- Extremely high working temperature with proper inert gas protection (>3000C has been recorded).

Hot Pressed Boron Nitride Ring Applications

Boron Nitride ceramics from Advanced Ceramic Materials can withstand high temperatures in a high vacuum environment, plus it has excellent corrosion resistance and electrical resistance. Thus, Boron Nitride ceramic product is an ideal choice in a wide range of industries, such as:

- Used in nozzles for the nonferrous metals metallurgy industry

- Used in insulators for high-temperature furnaces

- Used as break rings for a horizontal casting machine

- Used to feed through for high-voltage equipment

- Used in Boron Nitride parts for ion injection equipment

Hot Pressed Boron Nitride Ring Available Materials

| Material | Description | Availability |

| BN99 | Hot pressed at high temperature (1900℃). Excellent corrosion resistance and thermal conductivity. Limited wear resistance Self-bonded and high purity(>99%) |

Machinable Blanks Finished Parts |

| BNBO | General-purpose material Bonded by boric oxide |

Finished Parts |

| BNCB | Calcium borate bonded boron nitride Enhanced moisture resistance |

Finished Parts |

| BN60 | BN 60%, SiO2 40% | Finished Parts |

| BN40 | BN 40%, SiO2 60% | Finished Parts |

| ZSBN | BN-45%, Zr2O3 45% | Finished Parts |

Specifications of BN99 and ZSBN for your reference!

Packing Service

ACM's Hot Pressed Boron Nitride Ring is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

-

Attachment (Optional)

No file chosen