Silicon Nitride (Si3N4) Ceramics

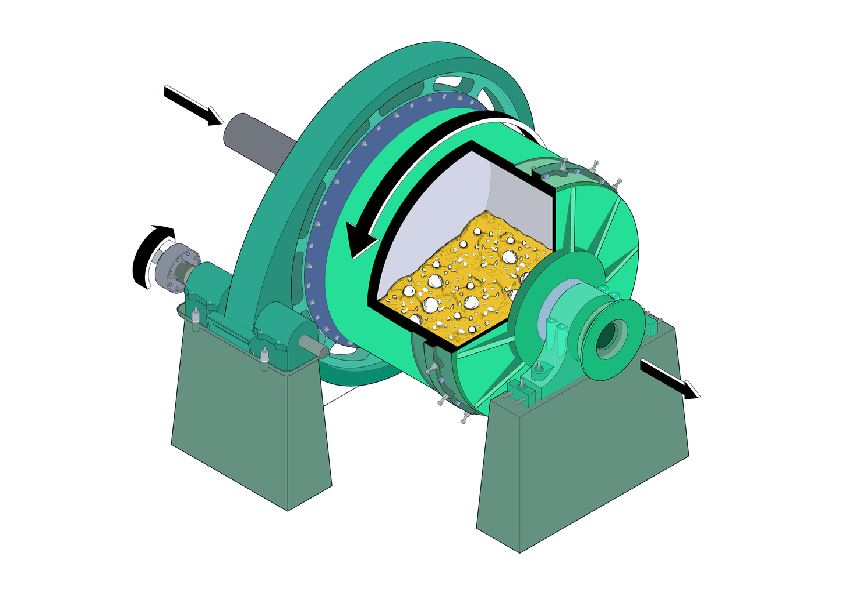

Silicon nitride (Si3N4) is a high-melting-point ceramic material that is extremely hard and relatively chemically inert. The material is prepared by heating powdered silicon between 1300 °C and 1400 °C in an atmosphere of nitrogen. Then the powder of silicon nitride can be sintered to the designed shape.

As one of the most thermodynamically stable technical ceramic materials with high hardness as well, silicon nitride ceramic is ideal for bearing parts, especially for those required to work at high speed and high temperature.

Further Reading: An Overview of Silicon Nitride Ceramics

Silicon Nitride Properties:

- Excellent thermal shock resistance

- High fracture toughness

- Resistant to impacts and shocks

- Resistant to high temperature, wear and oxidation

Silicon Nitride Ceramic Specification

| Color | Gray and Gray-black |

| Density | 3.2~3.25 g/cm3 |

| Hardness | HRA 92~94 |

| Highest Operating Temperature | 1300 ~1600 ℃ |

| Thermal Conductivity | 23-25 W.(M.K)-1 |

| Bending Strength | ≥ 900 Mpa |

| Fracture Toughness | 6~8 (Mpa.m1/2) |

| Thermal Expansion Coefficient (at 0~1400℃) | 2.95~3 ×10-6/℃ |

Silicon Nitride Ceramic Types

- Reaction-Bonded Silicon Nitride (RBSN)

- Hot Pressed Silicon Nitride (HPSN)

- Sintered Reaction-Bonded Silicon Nitride (SRBSN)

- Gas Pressure Sintered Silicon Nitride (GPSN)

- Sintered Silicon Nitride (SNN)

Read more: 5 Types of Silicon Nitride Ceramics

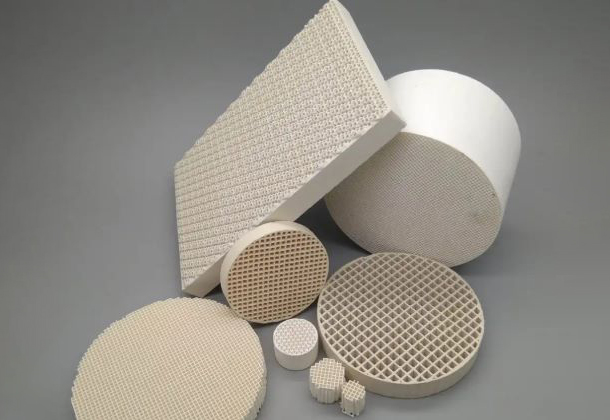

Silicon Nitride Ceramic Application

Si3N4 bearing balls have already been applied in automobiles, rockets high-speed engines, equipment working in a corrosive environment, and some performance model cars. Compared with steel, high-performance ceramic balls have better mechanical properties under high temperatures and could survive most corrosive chemicals.

Silicon nitride has also been used in high-temperature applications. It was considered as one of the few monolithic ceramic materials that could survive the severe thermal shock and thermal gradients generated in hydrogen-oxygen rocket engines.

ACM Ceramic Product Video

Your Si3N4 Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of silicon nitride ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us for any questions about Si3N4 or other ceramic materials that are not listed on the website.

| Chemical Formula | Si3N4 |

| Mechanical | |

| Density | 3.26 g/cm3 |

| Hardness | 14 GPa |

| Modulus of Elasticity | 300 GPa |

| Flexural Strength | 800 MPa |

| Compressive Strength | 3000 MPa |

| Poisson's Ratio | 0.28 |

| Fracture Toughness | 7 MPa m½ |

| Electrical | |

| Dielectric Strength | 13 ac V/mm |

| Dielectric Constant | 9.6 (@ 1 MHz) |

| Volume Resistivity | 10^14 ohm-cm |

| Thermal | |

| Coefficient of Thermal Expansion | 3.1 x 10^-6/°C |

| Thermal Conductivity | 17 W/(m*K) |

| Specific Heat | 0.65 x10^3 J/(Kg*K) |

| Shock Resistance | 800 °C Diff. |

| Maximum Working Temperature | 1300 °C |