The Compression Annealing Advantage for Pyrolytic Boron Nitride

Introduction

My years of experience with high-temperature materials have shown me, first-hand, how processing methods can fundamentally reshape a material's structure. Pyrolytic boron nitride is a classic case. It is produced using the thermal conversion of boron trichloride and ammonia vapors on a graphite surface heated to about 1,900 °C. This method yields a product with a density of 2.0 to 2.2 grams per cubic centimeter and very small crystalline grains. In many ways, its characteristics are similar to those of pyrolytic graphite. What makes the study of boron nitride particularly engaging is how its structure might be fine-tuned by heat treatments like compression annealing.

Preparation and Characteristics

Pyrolytic boron nitride is synthesized through the controlled thermal decomposition of chemical precursors at extreme temperatures. The substrate, usually a form of graphite, is prepared at high temperatures, and the reactants decompose and settle into layers. The boron nitride finds itself in thin, hexagonally arranged crystals, with the c-axes – or what we think of as its main direction – mostly pointing away from the substrate. In simpler terms, the tiny crystals are organized in a neat, layered pattern. Their sizes are roughly 50 to 100 Å, which makes them very small. They tend to have a spread or preferred orientation that is measured by the width at half of the maximum intensity. For boron nitride, this spread usually falls between 50° and 100°. These numbers may seem high or technical, but they help us gauge how uniform the structure is.

The Concept of Sublimation and Comparative Behavior

It is worth noting that pure boron nitride does not melt like usual materials. Instead, it sublimes. Under a single atmosphere of nitrogen, sublimation occurs at temperatures in the range of about 2,330° C to 3,000° C. Compare that with graphite, which is much more resistant to change, subliming only at higher temperatures like 3,700° C. These differences in high-temperature behavior point to why we must be careful when processing these materials. The stability of boron nitride at these temperatures makes it attractive for various high-temperature applications.

Annealing and Structural Refinement

It has long been known that pyrolytic graphite can be transformed to exhibit properties closer to those of single-crystal graphite through established thermo-mechanical techniques. Techniques such as high-temperature annealing or deforming the material either by pulling or by pressing have proven effective. The method we are focusing on here is compression annealing. This procedure works by applying pressure perpendicular to the lamellar, or layered, structure of the material while it is heated above approximately 2,800 °C. In practical terms, when the pressure is applied at high temperatures, the layers are forced closer together, which can lead to a more orderly arrangement. Many who have worked with pyrolytic graphite have seen this process help in reducing imperfections.

Given the likeness in both structure and properties between pyrolytic boron nitride and its graphite cousin, it seemed natural to ask: could compression annealing also modify boron nitride’s structure? In many practical tests, slight but significant changes have been observed. The hope is that by carefully pressing the material under heat, one might achieve improved crystalline order. For those of us who have spent long hours in the lab or on the shop floor, this possibility is as exciting as it is practical.

How Compression Annealing Works

The process of compression annealing is relatively straightforward in concept, yet it requires meticulous control when put into practice. The idea is to take the already-configured boron nitride layers and subject them to a uniform load at elevated temperatures. For best results, the pressure should be applied directly perpendicular to the basal planes – the flat, plate-like portions – of the material. This forces the crystallites into an even tighter packing. It is a bit like ironing out the wrinkles in a stack of delicate silk sheets without causing damage. Over time, the repeated use of high pressure at these temperatures softens the imperfections and can sometimes lead to properties that lend themselves better to high-performance applications.

Implications for Industrial Applications

For engineers working with high-temperature materials, even marginal structural improvements can yield significant performance gains. Compression annealing of pyrolytic boron nitride can result in enhanced thermal stability and mechanical strength. For instance, when used in high-temperature furnaces or as components in aerospace and defense systems, even slight improvements in material uniformity can mean longer life and better efficiency. In everyday applications, this might translate into fewer accidents or reduced maintenance costs, which is of great use in heavy industry and technical manufacturing.

It is not unusual to compare testing results with those obtained from other advanced materials. Historically, improvements in resin, ceramic, and composite materials have led to industry transformations. With pyrolytic boron nitride, the direct benefits of compression annealing include a more consistent crystal orientation and improved durability in service. These features are essential when the material is expected to perform reliably under repeated thermal cycling or mechanical stress.

Conclusion

In summary, compression annealing stands out as a promising process for refining the structure of pyrolytic boron nitride. I have worked with many materials over the past decades, and I find it encouraging to see that controlled pressure and heat can lead to measurable improvements. Whether you are a seasoned engineer or just starting your journey with high-temperature materials, the basic principles remain the same: attention to detail in the manufacturing process pays off. By embracing techniques like compression annealing, industry professionals can move closer to achieving ideal materials for demanding applications.

For anyone interested in obtaining high-quality pyrolytic boron nitride for further study or industrial use, Advanced Ceramic Materials (ACM) is a trusted supplier. Their products come with a long history of reliability and performance, ensuring you get the best care and quality possible.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

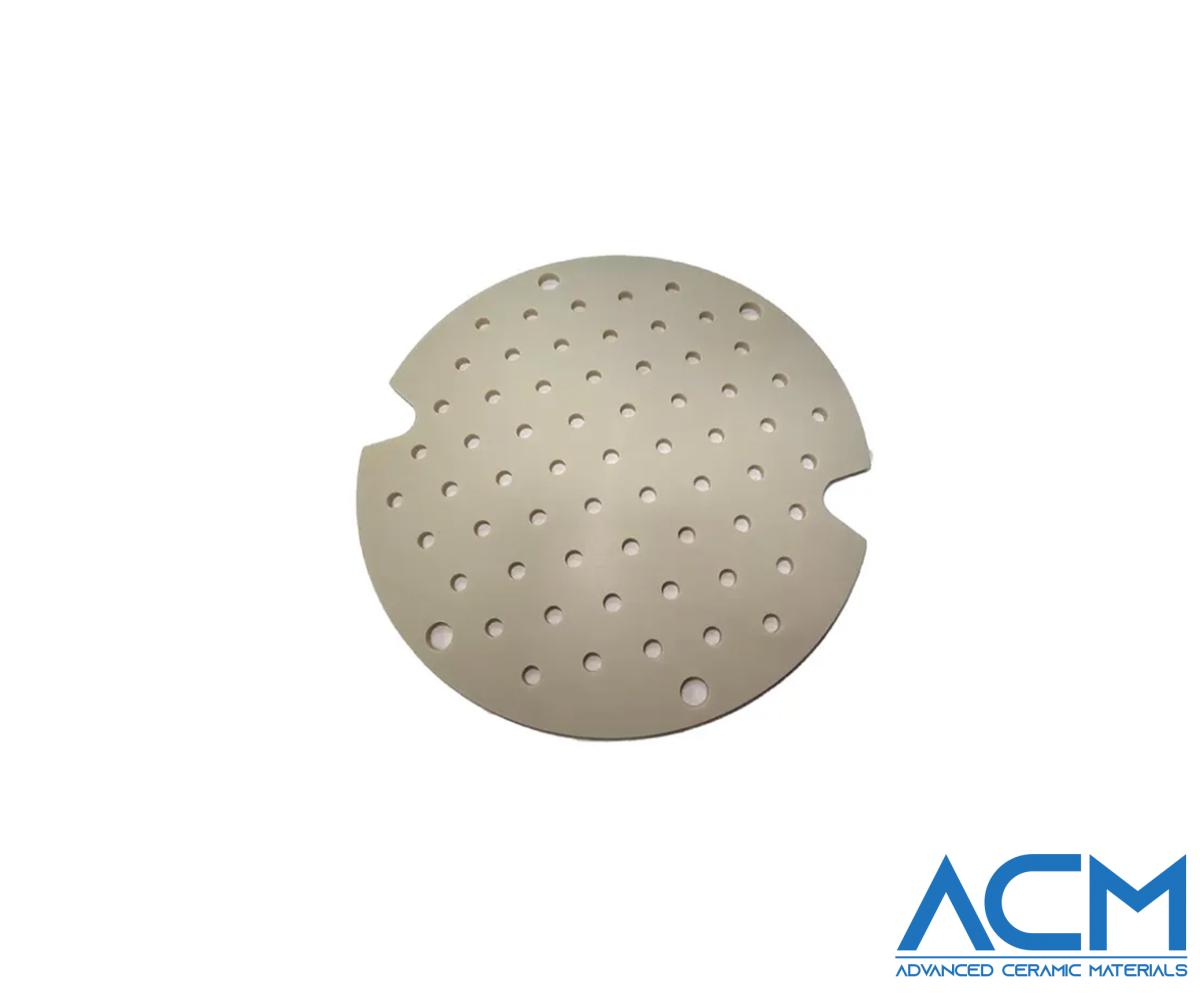

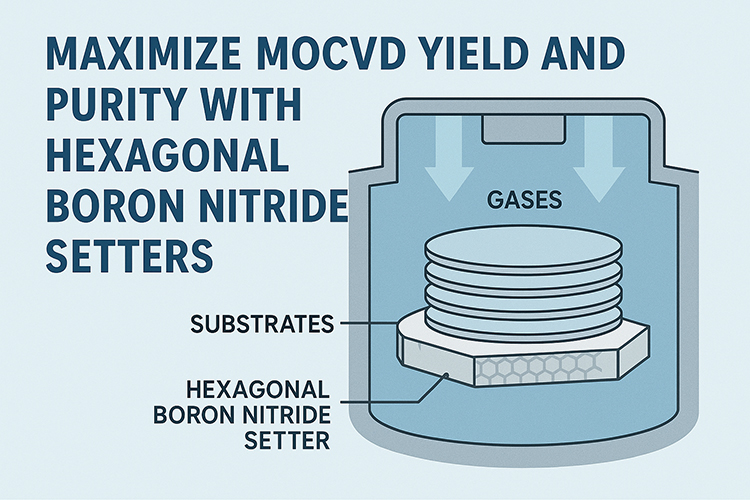

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity