Boron Carbide (B10) for Effective Neutron Shielding in Nuclear Radiation

1. Introduction

Nuclear radiation poses significant risks to human health and the environment. Effective shielding is essential in industries like nuclear power, medical imaging, and aerospace to mitigate these risks. Among various shielding materials, boron carbide stands out due to its unique ability to absorb neutrons efficiently.

This article explores the properties, mechanisms, and applications of boron carbide in radiation shielding, highlighting its role as a critical material in enhancing safety across diverse fields.

2. Nuclear Radiation and Shielding: Need for Protection

Nuclear radiation originates from various sources, including natural radioactive elements, nuclear power plants, and medical applications like radiotherapy. Among different types of radiation, neutron radiation is particularly harmful due to its ability to penetrate deep into materials and interact with atomic nuclei. Prolonged exposure to neutron radiation can damage human tissues, alter DNA, and increase the risk of cancers.

Effective radiation shielding is critical to protect human health and the environment. Shielding materials must be capable of absorbing or deflecting harmful radiation while maintaining structural integrity under harsh conditions. In this context, boron carbide has gained attention as a highly effective material for neutron absorption. Its superior neutron-capturing ability, combined with its lightweight and durability, makes it an excellent choice compared to traditional materials like lead or concrete.

3. Properties of Boron Carbide

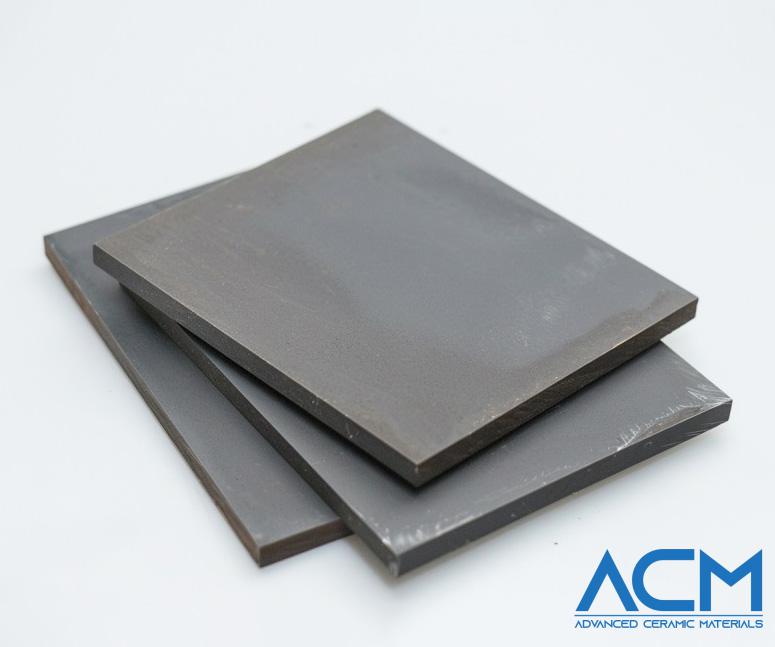

Boron carbide is a ceramic material known for its exceptional hardness, lightweight nature, and thermal stability. These properties make it not only a preferred material for neutron shielding but also suitable for various high-stress applications.

-

Physical and Chemical Properties:

Boron carbide is one of the hardest materials available, ranking just below diamond and cubic boron nitride. Its high hardness ensures durability under extreme conditions, while its low density allows for lighter shielding solutions compared to heavier materials like lead. Additionally, boron carbide exhibits excellent thermal resistance, maintaining its integrity even in high-temperature environments such as nuclear reactors.

-

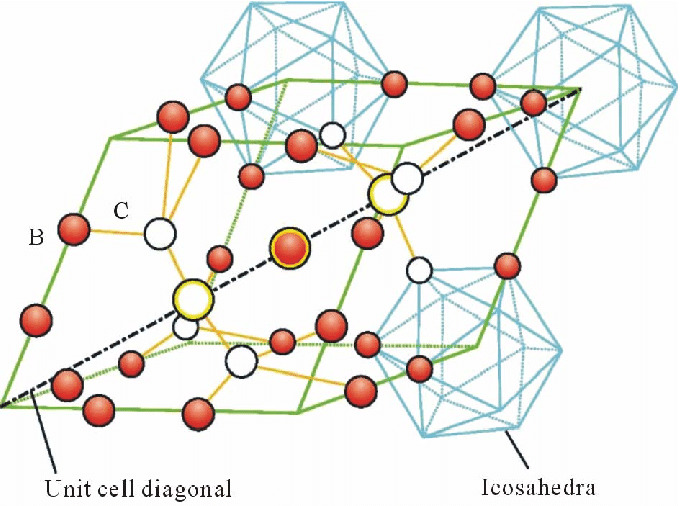

Unique Isotopic Composition:

Boron naturally occurs as two isotopes: B-10 and B-11. Among these, B-10 is highly effective in neutron absorption due to its ability to capture thermal neutrons through the nuclear reaction B-10(n,α)Li-7. This reaction not only neutralizes the neutron but also produces harmless byproducts. The high concentration of B-10 in boron carbide is what sets it apart as a superior neutron shielding material.

With these properties, boron carbide combines strength, efficiency, and practicality, making it a vital material in the development of advanced radiation shielding technologies.

4. Neutron Shielding Mechanism of Boron Carbide

The effectiveness of boron carbide in neutron shielding lies in its unique ability to capture and neutralize neutrons. This property is primarily due to the high concentration of the boron-10 (B-10) isotope, which has an exceptional cross-section for thermal neutron absorption.

-

Neutron Absorption Process:

10B+n→7Li+α+Energy

When a thermal neutron collides with a B-10 nucleus, a nuclear reaction occurs:This reaction produces lithium-7 (Li-7) and an alpha particle (α), both of which have minimal penetrating power and do not pose significant risks. The energy released during the reaction is dissipated harmlessly as heat.

-

Comparison with Other Materials:

Compared to traditional shielding materials like lead or water, boron carbide offers superior neutron absorption efficiency at a significantly lower weight. For example, while materials like lead are effective for gamma radiation, they are less effective against neutrons, which require materials with high neutron cross-sections, like boron carbide. -

Design Considerations:

The performance of boron carbide shielding depends on factors such as material density, thickness, and arrangement. Combining boron carbide with other materials (e.g., concrete or polymers) can enhance its shielding capabilities while optimizing weight and cost for specific applications.

Through its efficient neutron absorption mechanism, boron carbide provides a lightweight, durable, and highly effective solution for mitigating neutron radiation in diverse settings.

5. Applications of Boron Carbide in Nuclear Radiation Shielding

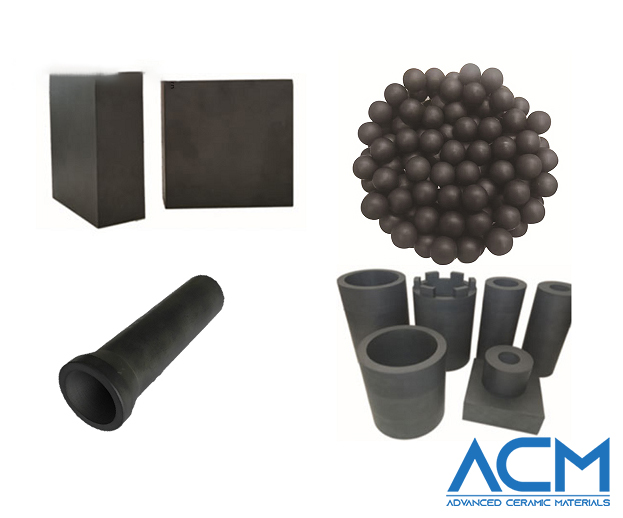

Boron carbide is a valuable material for neutron shielding across various industries. Its lightweight, durability, and efficient neutron absorption capability have driven its adoption in critical applications.

-

Nuclear Power Plants:

Nuclear boron carbide is widely used in nuclear reactors as a neutron absorber. It plays a critical role in control rods, which regulate the fission process by capturing excess neutrons. Additionally, it is used in shielding materials for reactor walls and spent fuel storage containers, protecting workers and the environment from neutron radiation.

-

Aerospace and Aviation:

In aerospace applications, boron carbide helps mitigate the effects of cosmic neutron radiation. Lightweight shielding panels made from boron carbide are used in spacecraft and satellites to protect sensitive equipment and ensure the safety of crew members during prolonged space missions. Its low weight makes it ideal for applications where minimizing mass is essential. -

Medical Applications:

In the medical field, boron carbide is utilized in radiation therapy equipment to shield healthy tissues during neutron-based cancer treatments. It also protects facilities where radioactive isotopes are used, ensuring that medical personnel and patients are not exposed to harmful neutron radiation.

These applications demonstrate how boron carbide combines its physical properties and neutron absorption capabilities to address the diverse demands of nuclear radiation shielding.

6. Conclusion

Boron carbide has proven to be a critical material for neutron shielding in nuclear radiation applications. Its lightweight nature, exceptional durability, and efficient neutron absorption capabilities make it a superior choice compared to traditional shielding materials. By utilizing the boron-10 isotope’s unique ability to capture neutrons, boron carbide plays a vital role in protecting people and equipment across industries such as nuclear energy, aerospace, and medicine.

Advanced Ceramic Materials (ACM) specializes in supplying high-quality boron carbide solutions tailored to meet the demanding requirements of modern radiation shielding. With proven performance and adaptability, boron carbide continues to be an essential material for ensuring safety and reliability in environments exposed to neutron radiation.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

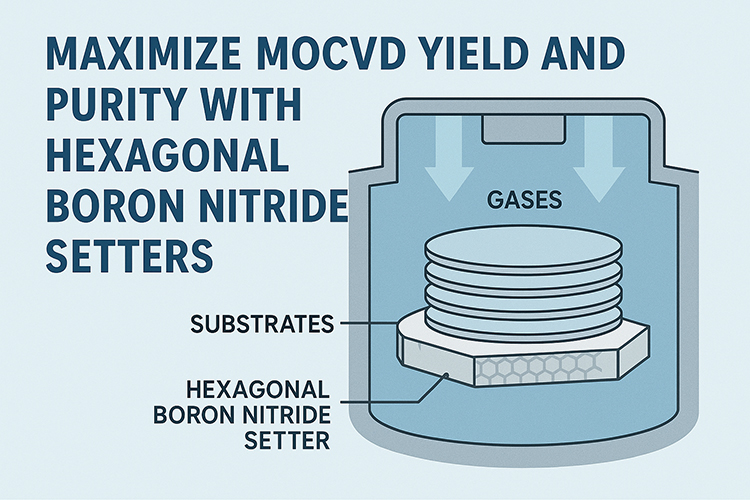

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity