Cesium Carbonate Ceramic: Enhancing the Capacity and Durability of Batteries

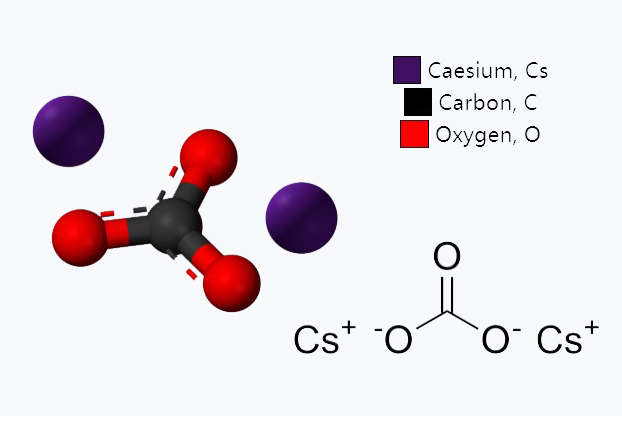

In the rapidly advancing world of energy storage, cesium carbonate ceramic (Cs2CO3) is making significant strides in improving battery performance. Traditionally used in organic synthesis and catalysis, this versatile compound is now finding crucial applications in battery materials, particularly in conductive ceramics. By enhancing capacity, durability, and overall efficiency, cesium carbonate ceramic is becoming an essential component in the quest for better batteries. Let's explore how this material is revolutionizing the battery industry and what makes it so effective.

The Role of Cesium Carbonate Ceramic in Batteries

Cesium carbonate ceramic has garnered attention for its unique properties that contribute to the efficiency and longevity of batteries. Here’s how:

-

Improved Ionic Conductivity: Cesium carbonate ceramic is known for its high ionic conductivity, which is crucial for the efficient functioning of batteries. When used in solid electrolytes, it facilitates the smooth movement of ions, reducing internal resistance and enhancing the overall performance of the battery.

-

Enhanced Stability: One of the significant challenges in battery technology is maintaining stability over prolonged usage. Cesium carbonate ceramic contributes to the thermal and chemical stability of the battery components, ensuring that they can withstand high temperatures and reactive environments without degrading.

-

Increased Capacity: Batteries aim to store as much energy as possible within a given volume. Cesium carbonate ceramic aids in increasing the energy density of batteries. Its incorporation into the electrode materials allows for a higher charge storage capacity, resulting in batteries that can last longer on a single charge.

-

Durability and Longevity: The durability of a battery is a measure of how many charge-discharge cycles it can undergo before its performance deteriorates. Cesium carbonate ceramic enhances the structural integrity of the battery materials, reducing wear and tear during cycling and thereby extending the battery's lifespan.

Applications of Cesium Carbonate in Conductive Ceramics

Conductive ceramics are essential components in modern batteries, providing the necessary conductivity while maintaining structural stability. Cesium carbonate ceramic plays a vital role in these materials:

-

Composite Electrodes: Cesium carbonate ceramic is used in the fabrication of composite electrodes, where it acts as a dopant to improve the electronic properties of the ceramic materials. This enhancement leads to better charge distribution and increased efficiency of the battery.

-

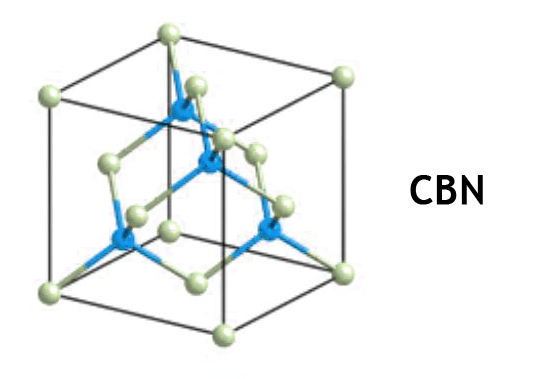

Solid Electrolytes: In solid-state batteries, cesium carbonate ceramic is utilized in the production of solid electrolytes. These electrolytes offer superior ionic conductivity and stability compared to their liquid counterparts, making them ideal for next-generation battery technologies.

-

Thin-Film Batteries: The development of thin-film batteries, which are lightweight and have a high power-to-weight ratio, benefits from the use of cesium carbonate ceramic. It contributes to the formation of thin, uniform films with excellent conductive properties, crucial for the miniaturization of electronic devices.

Cesium Carbonate Ceramic in Emerging Battery Technologies

As the demand for more efficient and durable batteries continues to grow, the role of advanced materials like cesium carbonate ceramic becomes increasingly significant. Researchers are actively exploring new formulations and applications to maximize the benefits of this versatile compound. These advancements include:

- Hybrid Materials: Combining cesium carbonate ceramic with other conductive materials to create hybrid electrolytes and electrodes that offer superior performance metrics.

- Nanostructured Components: Utilizing cesium carbonate ceramic in the development of nanostructured battery components to further enhance conductivity and stability at the microscopic level.

- Sustainable Practices: Investigating the environmental impact of cesium carbonate ceramic production and utilization, ensuring sustainable practices in its application within the battery industry.

Conclusion

Cesium carbonate ceramic is proving to be a valuable addition to the arsenal of materials used in modern battery technology. Its ability to enhance capacity, stability, and durability positions it as a key ingredient in the quest for more efficient and long-lasting batteries. As research and development continue to unlock the potential of cesium carbonate ceramic, we can expect significant advancements in energy storage solutions that will power the technologies of tomorrow. Advanced Ceramic Materials (ACM) remains at the forefront of providing high-quality cesium carbonate ceramic and other advanced materials, driving innovation in the battery industry.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}