How to Make Hexagonal Boron Nitride Powder?

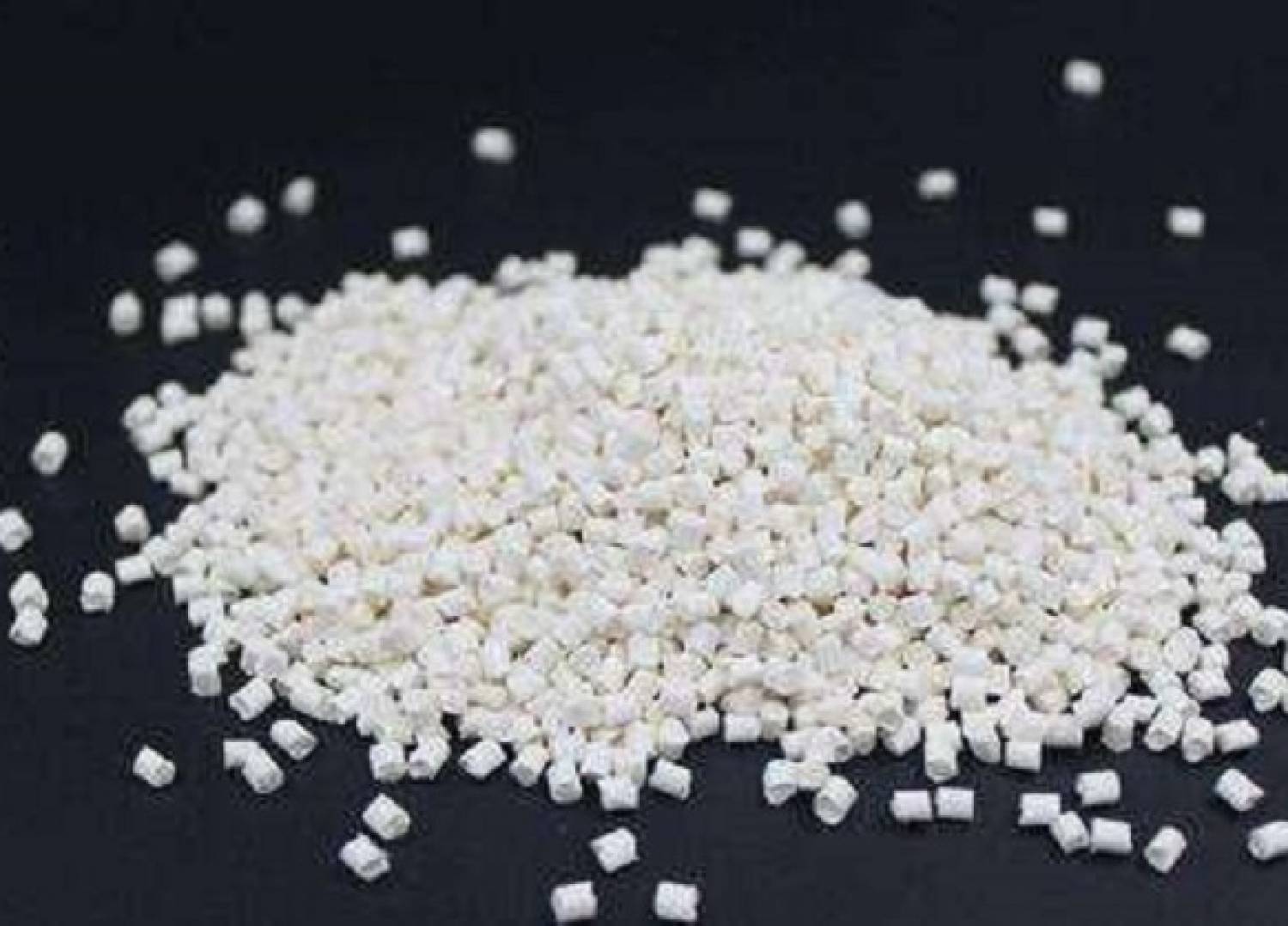

Boron nitride is a new type of ceramic material with excellent performance and great potential for development. Hexagonal boron nitride (h-BN) is an isomer of boron nitride. Its structure is similar to that of graphite. It has a hexagonal layer structure, soft texture, and high processability. Its color is white, commonly known as "white graphite." Let me introduce you to the commonly used method of making hexagonal boron nitride powder.

Chemical Vapor Deposition (CVD) Method

The h-BN powder prepared by the CVD method generally adopts a hot wall reactor, and the gaseous raw materials containing B and N are introduced into a reaction chamber through a carrier gas, and a chemical reaction occurs between the gaseous raw materials at a high temperature to form a BN powder. Among them, boron sources generally use boron-containing compounds such as BF3, BCl3, BBr3, B2H6, and B(OCH3)3, and the nitrogen source is generally NH3 or N2. The purity and sphericity of the h-BN powder prepared by the CVD method are high, making it suitable for various applications. However, precise control of factors such as temperature, pressure, gas flow rates, and reaction time is crucial to achieve desired product characteristics.

Borax – Urea Method

The borax-urea method is a traditional and cost-effective approach for synthesizing h-BN powder. The boron hydride is mixed with urea (ammonium chloride) and heated in an ammonia gas stream to obtain boron nitride.

The reaction equation is:

Na2B4O7+2(NH2)2CO→4BN+Na2O+4H2O+2CO2

Na2B4O7+2NH4Cl+2NH3→4BN+2NaCl+7H2O

The borax-urea (ammonium chloride) method is a traditional method for preparing h-BN powder, which has low production cost, low investment, and a simple process. This method is more suitable for industrial production because the boron nitride obtained by the synthesis is not high in purity and has poor particle size uniformity.

The Hydrothermal Method

The water (solvent) thermal synthesis method, referred to as the hydrothermal method, is to use water (or organic solvent) as a reaction medium in an autoclave to heat a high-pressure autoclave to create a high temperature and high-pressure reaction environment. In such an environment, substances that are generally poorly soluble or insoluble can be dissolved and reacted to form new crystals. The hydrothermal method is usually used to synthesize oxide or metal element ultrafine powder, and research on the preparation of non-oxide superfine powder is still in its infancy. The process conditions of the hydrothermal method are relatively easy to control, the product particle size can reach the nanometer scale, and the uniformity and the sphericity are good, but the yield is generally low. Therefore, the selection of suitable solvents, raw materials, and additives to reduce the reaction temperature (large-scale production below 240 °C) and increase the yield will be the focus of future research.

Conclusion

Hexagonal boron nitride powder is a highly versatile material with widespread applications. Various methods, including chemical vapor deposition (CVD), the borax-urea method, and the hydrothermal method, are employed to produce h-BN powder. Each method offers unique advantages and considerations, such as purity, particle size uniformity, cost, and process complexity.

Understanding these manufacturing techniques will contribute to the advancement of hexagonal boron nitride ceramics and their diverse applications. With its excellent performance and potential for development, h-BN continues to be an important material in various industries. To explore further and access high-purity h-BN powder at a reasonable price, interested individuals can visit manufacturers like Advanced Ceramic Materials at https://www.preciseceramic.com/.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments