SM6076 Glass Bead

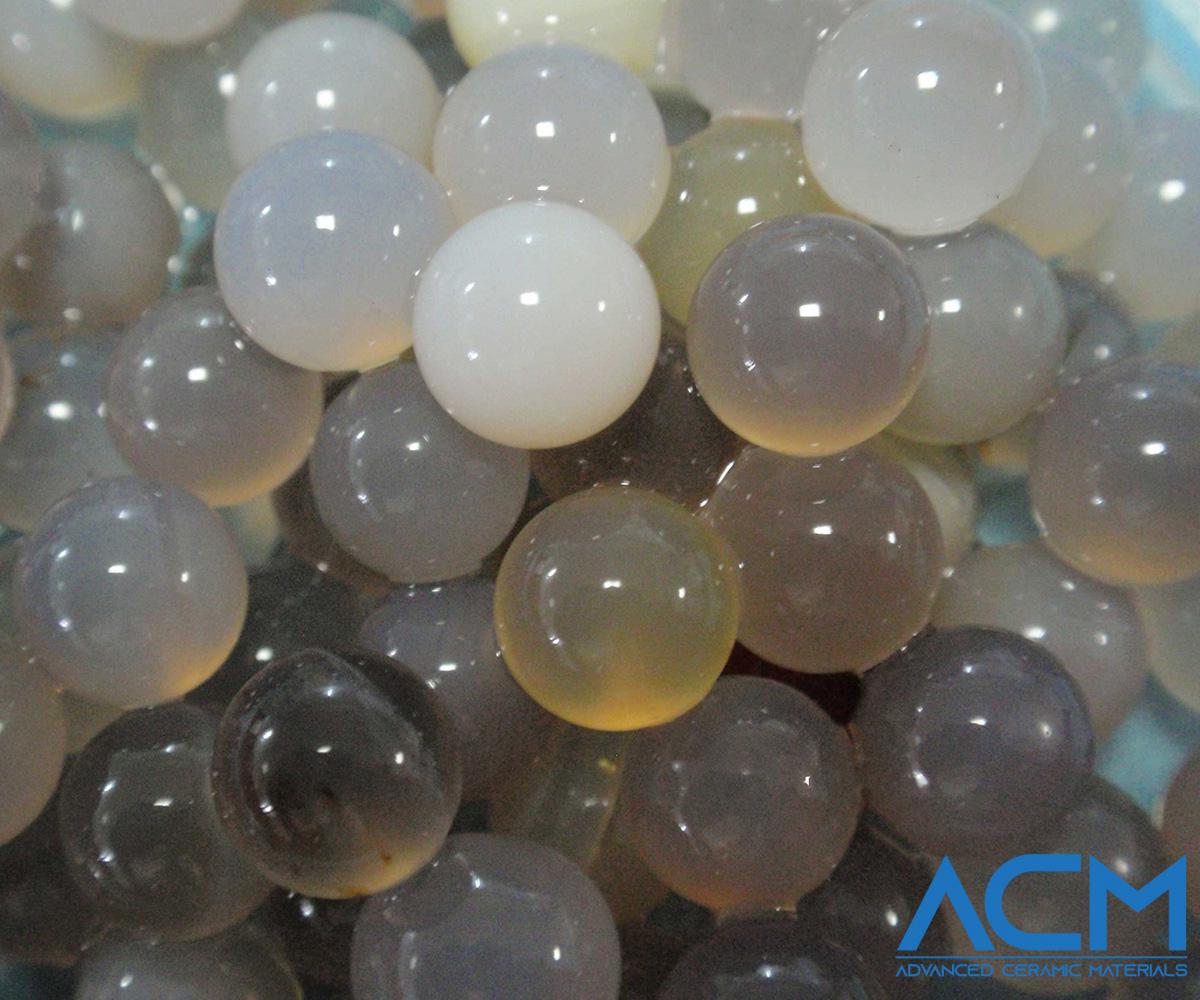

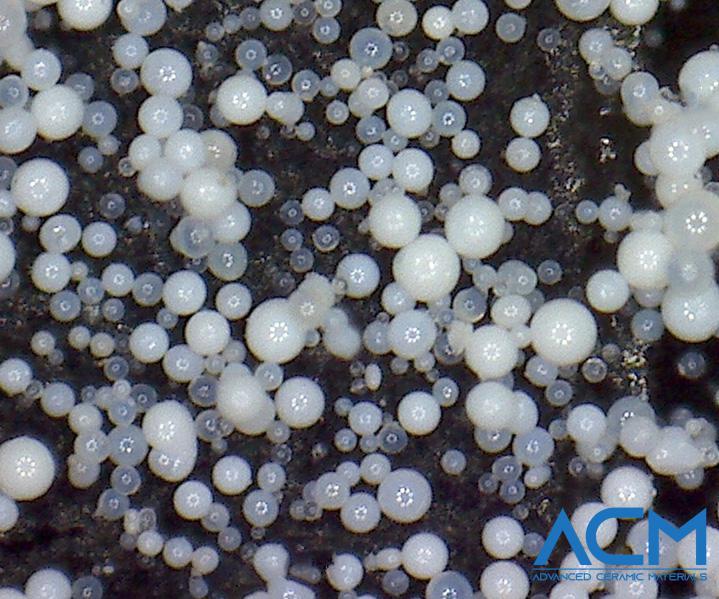

Glass Bead Overview

Glass Beads are produced using advanced techniques such as direct melting of new glass, titration, forming in deionized water, high-temperature hardening, and polishing. They have perfect sphericity and are free of air bubbles, ensuring superior wear resistance. These beads are ideal for cost-effective dispersion and grinding of low-viscosity slurries, making them well-suited for traditional sand mills.

Glass Bead Specification

|

Specific Gravity |

2.5kg/dm3 |

|

Bulk Density |

1.5kg/L |

|

Mohs Hardness |

≥6 |

|

Vickers hardness |

630kg/mm2 |

|

Elastic Modulus |

63Gpa |

|

Minimum Order Quantity (MOQ) |

25kg/drum |

Chemical Composition

|

Chemical Composition |

SiO2 |

Na2O |

CaO |

Al2O3 |

MgO |

Others |

|

Wt% |

70 |

14 |

12 |

1 |

2 |

1 |

Specification

- Bead

|

Model |

Diameter (φ) mm |

|

NS4 |

0.40-0.60 |

|

NS5 |

0.50-0.75 |

|

NS7.5 |

0.75-1.00 |

|

NS10 |

1.00-1.30 |

|

NS12.5 |

1.25-1.55 |

|

NS15.5 |

1.55-1.85 |

|

NS17 |

1.70-2.00 |

|

NS20 |

2.00-2.40 |

|

NS24 |

2.40-2.85 |

|

NS28.5 |

2.85-3.35 |

|

NS30 |

3.00-3.50 |

|

NS35 |

3.50-4.00 |

- Ball

|

Model |

Diameter (φ) mm |

|

NSB8 |

8 |

|

NSB9 |

9 |

|

NSB10 |

10 |

|

NSB11 |

11 |

|

NSB12 |

12 |

|

NSB13 |

13 |

|

NSB14 |

14 |

|

NSB15 |

15 |

|

NSB16 |

16 |

|

NSB17 |

17.0 |

|

NSB18 |

18 |

|

NSB20 |

20 |

*Sizes can be tailored to meet specific customer requirements.

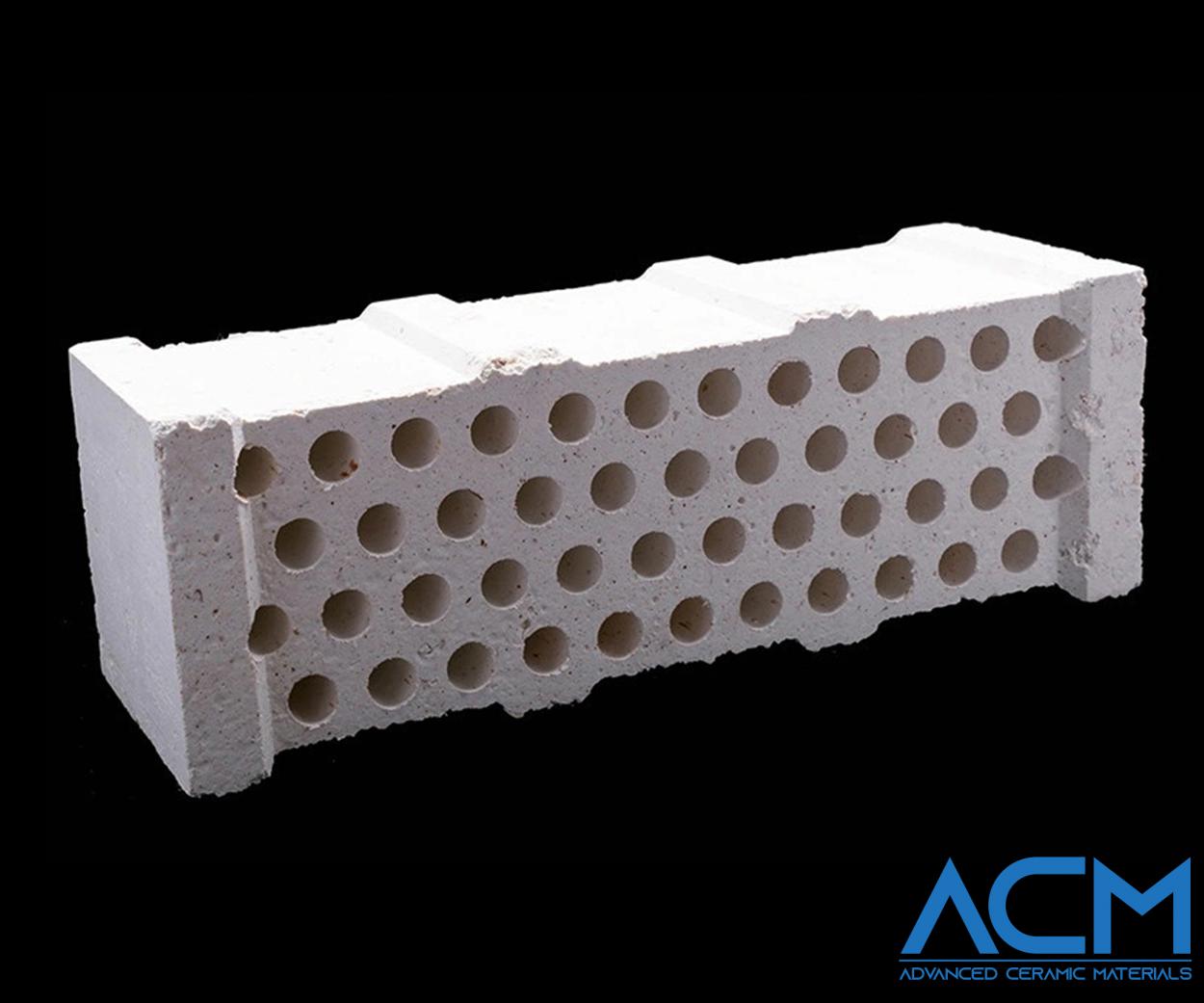

Glass Bead Applications

- Grinding Media: Utilized in the chemical and biological sectors for processing pigments, dyes, paints, inks, varnishes, pesticides, and pharmaceuticals.

- Filtration Media: Employed as filtration media, catalyst carriers, and for polishing and cleaning applications.

- Sealing Components: High-precision glass beads are suitable for use as sealing components.

Glass Bead Packing

Packaged in 25 kg drums and available in composite woven bags or drums.

-

Attachment (Optional)

No file chosen