Why is Silicon Carbide Used in Semiconductors

Silicon Carbide, sometimes mistakenly referred to by the trade name Carborundum. Silicon Carbide is widely used in the manufacture of heating elements, slide bearings, sealing rings, wear parts, sintering aids, crucibles, burner nozzles, heat exchangers. Silicon Carbide also has the resistivity necessary to perform as a semiconductor material.

![]()

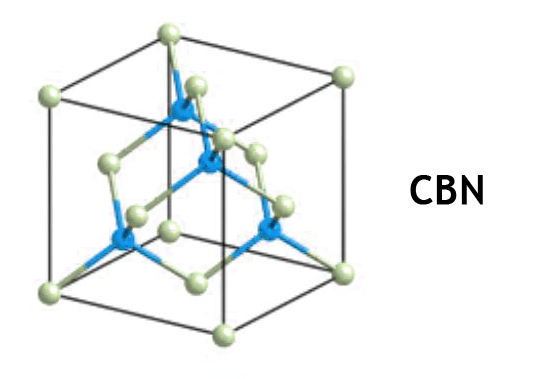

Silicon carbide is not only the lightest, but also the hardest ceramic material and has excellent thermal conductivity, low thermal expansion and is very resistant to acids and lyes. Silicon Carbide (SiC) devices belong to the so-called wide band gap semiconductor group. They offer a number of attractive characteristics for high voltage power semiconductors when compared to commonly used silicon (Si). Silicon carbide behaves almost like a diamond. It is toxicologically safe and can be used in the food industry. In particular, the much higher breakdown field strength and thermal conductivity of SiC allow creating devices which outperform by far the corresponding Si ones.

![]()

Another typical application for silicon carbide components is dynamic sealing technology using friction bearings and mechanical seals, for instance in pumps and drive systems. ![]()

With silicon carbide ceramics the material properties remain constant up to temperatures above 1,400°C. Compared to metals, silicon carbide enables highly economical solutions with longer tool life when used with aggressive, high-temperature media. Silicon carbide ceramics are also ideal for use in demanding conditions in energy technology, paper manufacturing, ballistics, chemical production, and as pipe system components due to its great properties.

TYPICAL PROPERTIES

- High Hardness

- Chemical Inertness

- hermal Shock Resistance

- Abrasion / Wear Resistance

- Strength at High Temperature Ranges

- Electrical Conductivity

- High Thermal Conductivity

- Abrasive

- Low Coefficient of Thermal Expansion

Please visit https://www.preciseceramic.com/ for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}